Catalog excerpts

Intelligent solutions for complex machining tasks

Open the catalog to page 3

INTERCHANGEABLE HEAD MILLING CUTTER Flexible, wear-resistant, highly accurate: The interchangeable head milling cutter, consisting of cutting head and clamping chuck, can be refitted with a new head in seconds. Axially and radially adjustable as well as extreme clamping force, it promises accurate concentricity. Exceptional performance with maximum cutting rates and reduced machining times. This publication may not, in part or whole, be reproduced. The publishers cannot be held responsible forany errors, omissions or changes of any kind. All products marked with “DIN“, deviating from the...

Open the catalog to page 4

With Guhring’s roughing tool cylinder bore surfaces are mechanically roughened for a high tensile strength of thermally sprayed coatings. Roughing tool

Open the catalog to page 5

High-performance tool material combined with innovative technologies Longstanding expertise The development and manufacture of PCD/CBN tools has counted to Guhring’s core activities for more than 30 years. At Guhring production facilities all over the world innovative complex tools with PCD/CBN cutting edges are produced for highly specialised machining operations. More performance, less tooling PCD/CBN complex tools from Guhring guarantee short cycle times and high feed rates with consistent quality, exact repeatability and accuracy. High wear-resistance results in long tool life and...

Open the catalog to page 6

water Jacket bore

Open the catalog to page 7

Optimal co-ordination of all tool parameters thanks to own R&D sectors 1 TOOL MATERIALS MACHINE & EQUIPMENT DIVISION Own machine tool and equipment divisions Own coating systems and own coating development

Open the catalog to page 8

Everything from one supplier – comprehensive and global Approximately 500 employees world-wide develop, produce and distribute innovative PCD/CBN tools at Guhring. Many of our customers value the many years of know-how in the conception of PCD/CBN special tools that we manufacture according to individual requirements and design for customers in the automotive industry, the aerospace industry or the mechanical engineering industry. A world-wide net of production centres develops and produces Guhring PCD/CBN high-tech tools for all important global markets. With many years of know-how,...

Open the catalog to page 9

ancillary components Page 38 Page 40 Page 42 Page 44 Page 46 Page 48 Page 50 Page 52 Brake caliper Brake cylinder Brake disc Wheel carrier Axle uprights Steering column Joint machining Pump housing Turbocharger Page 12 Page 20 Page 24 Gear Valve housing Cylinder head Cylinder head cover Crankcase Page 56 Page 58 Page 60 Special solutions

Open the catalog to page 10

Aerospace lightweight construction Standard tools and ISO inserts Page 78 Technical section MQL Basics Values for cutting speeds Modules 6x6 and 4x4 Setting and handling notes 08 09 Page Page Page Page

Open the catalog to page 11

Autom Special requirements, precise solutions

Open the catalog to page 12

motive Modern automotive manufacturing relies on the application of high specification materials that are sometimes difficult to machine. Typical components such as engine blocks, cylinder heads or transmission housings put special demands such as wear-resistance and accuracy and – fields of application ideally suited to PCD complex tools from Guhring. On the following pages we present some tooling solutions developed by us for the engine and other automotive components, transmissions and chassis parts.

Open the catalog to page 13

cylinder head

Open the catalog to page 14

Highest performance thanks to highly accurate machining Guhring designs and manufactures PCD tools for all machining tasks related to modern high performance engines. Machining componenets such as the cylinder head or crank case requires many closely positioned holes, the machining of which generates high temperatures. Due to such heat there is a risk of deformation of the precision holes. Guhring’s PCD tools possess special cutting edge geometries. The risk of deformation is significantly reduced and accurate holes guaranteed.

Open the catalog to page 15

MOTOR Cylinder head Water jacket bore This system for chip evacuation is ideally suited for holes when chips are not permitted to enter inside the workpiece. The special geometry of the water jacket drill ensures the chips are directed away from the workpiece. Contamination of the cylinder head is, therefore, greatly reduced. Water jacket bore Finish machining of valve seat insert and valve guide parent metal This solid carbide version offers highest rigidity and is resistant against erosion from abrasive materials. Not adjustable.

Open the catalog to page 16

The diameter is adjustable with the use of the expansion joint. expansion joint expansion screw The reamer diameter is also adjustable with the use of the expansion screw. Finish machining of valve train guide / insert Not adjustable, however, it is possible to correct the concentricity. Fine adjustment of the reamer’s concentricity is possible with the assistance of 4 adjusting screws on the cutting head. adjusting screws rigid insert seat Finish machining of valve train guide / insert Adjustable. adjusting screws axial and angle adjustment is possible 13 motor Drive ancillary components...

Open the catalog to page 17

MOTOR Cylinder head Control cuts Spring seat tool This tooling concept combines several tool types and hence reduces the machining time for the spring seat considerably. The application of 1-shot versions must always be individually checked for every machining process.

Open the catalog to page 18

motor Drive ancillary components Axles and steering Brakes special solutions Aerospace The PCD-tipped option is also available as a solid carbide tool. Finish machining The specially developed cutting edge geometry as well as the arrangement of the cutting edges provide optimal accuracy and short cycle times while maintaining consistent quality. HVA machining This 1-shot version combines the pre- and finish machining for the hydraulic valve compensation bore. The application of 1-shot versions must always be individually checked for every machining process.

Open the catalog to page 19

MOTOR Cylinder head Camshaft bearing tool z=1 PCD reamer for machining camshaft bearing seats in aluminium cylinder heads. The possibility of axial and radial adjustment of the cutting edges guarantees an individual adaptation to the machining task. With the userfriendly setting philosophy the cutting edges can be adjusted effortlessly from one side. In addition to this product, the adjusting device EV-600 is also available from Guhring to perform the radial and axial fine adjustment of the tool.

Open the catalog to page 20All GÜHRING catalogs and technical brochures

-

AEROSPACE

4 Pages

-

the best cast

36 Pages

-

DRILLING TOOLS

910 Pages

-

Grooving Systems

112 Pages

-

SuperLine 2016

148 Pages

-

GE 100 Floating holder

4 Pages

-

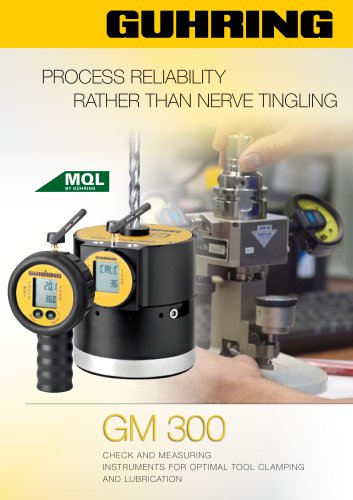

GM300_2015

228 Pages

-

GSS3001

5 Pages

-

Guhring Tool holders

4 Pages

-

GM 300 - MQL-Program

56 Pages

-

HMC 3000

6 Pages

-

TSG 3000

8 Pages

-

GSS 2000

12 Pages

-

PCD and CBN tools

20 Pages

-

PCD-Highlights AMB 2014

2 Pages

-

Stainless steels

18 Pages

-

Tools for the mould and die industry

112 Pages

-

Turbochargers PR 1000 M

6 Pages

-

MILLING TOOLS - 2014

332 Pages

-

CONVENTIONAL gun drills

60 Pages