Catalog excerpts

economic efficiency and quality for complex machining tasks

Open the catalog to page 1

PCD and CBN tools from Guhring page 5 Guhring is one of the leading suppliers of PCD and CBN tools with world-wide production and service facilities. From natural diamond to synthetic PCD and CBN page 6 A natural diamond possesses numerous characteristics that makes it the ideal tool material. However, the industry believes it is not perfect enough. This is the reason why synthetic tool materials such as PCD and CBN were developed. Advantages and application ranges page 8 PCD and CBN tools are especially suitable for the machining of difficult-to-machine, highly abrasive materials offering...

Open the catalog to page 3

The new plant II in Albstadt / Germany Choongnam / Korea

Open the catalog to page 4

PCD and CBN tools from Guhring Global know-how he development and production of PCD and CBN tools has been one of Guhring‘s high-tech sectors since the mid 80‘s. At three production locations, Germany, Czech Republic and USA, innovative and complex tools are developed globally for highly specialised machining tasks. New PCD and CBN production Centre-piece of our PCD and CBN production is our facility in Albstadt, located in a purposebuilt, state-of-the-art building since early 2004. Here, a workforce of approximately 200 develops and produces predominantly customer specific special tools...

Open the catalog to page 5

From natural diamond… Wonder of nature s the hardest natural mineral the diamond is ideally suited for machining other materials. It also possesses extreme hardness as well as very sharp cutting edges if machined accordingly. For example, a diamond will scratch any other mineral but cannot be scratched by any other stone itself. Treasure from the deep Natural diamond consists of pure carbon and graphite. It was created millions of years ago in the earth‘s crust through complex geological processes. At a depth of 130 to 700 kilometres below the earth‘s surface there were large quantities of...

Open the catalog to page 6

… to synthetic PCD and CBN PCD – a super-hard tool material ecause diamonds have always been very valuable, mankind has attempted to artificially recreate diamonds – by means of magic and alchemy of course without success. However, natural science has increasingly unearthed the secret of the diamond and opened the door for a synthetic production. 20 tons per annum The first synthetic diamond was created at General Electric, USA in 1955. More or less simultaneously, ASEA in Sweden developed a similar process. With this special process, at a temperature between 1500° C and 1800° C and a...

Open the catalog to page 7

Advantages of PCD and CBN tools Powerful and economical ools with PCD and CBN cutting edges are the ideal solution for difficult-to-machine, highly abrasive materials. These tools achieve highest quality and economic efficiency. The result: Long tool life, highest surface quality, optimal process reliability and repeatability. CFK is probably the most suitable future material applied in the aircraft industry thanks to its high rigidity and low weight. A consequence of this development is the difficult machining. The abrasive wear leads to a visible rounding of carbide cutting edges within a...

Open the catalog to page 8

Assembly of the new Airbus A380 Where the precision of Guhring tools counts. Photograph: Airbus S.A.S. Application Satisfying highest demands CD is especially suitable for the drilling, milling and reaming of non-ferrous materials, light and heavy metals, fibre-reinforced plastics, ceramics as well as synthetic glass. CBN is especially efficient for the machining of hardened steels and pearlitic cast materials. These materials are currently specifically applied in the automotive and aerospace industry as well as in the machine tool industry.

Open the catalog to page 9

Field of application - Aircraft industry High-tech and the dream of flying The solution: Guhring‘s PCD and CBN know-how In many cases it is the high hardness and the very sharp cutting edges of PCD and CBN tools that actually makes the machining of modern materials applied in the aerospace industry possible. In addition, Guhring‘s extensive know-how in the PCD and CBN sector regarding the design of tools and machining Airbus application: Guhring tools with PCD cutting edges 10 GUHRING PCD and CBN tools processes ensures that the tools developed by Guhring achieve the required quality and...

Open the catalog to page 10

Field of application - Automotive industry Better performance - less fuel consumption Multi-faceted application: Milling, drilling and reaming of a transmission housing. ightweight construction for better performance and less fuel consumption in the automotive industry is leading increasingly to the application of special materials such as aluminium and magnesium alloys in this field. Typical workpieces are, for example, engine blocks, cylinder heads, crankshafts and camshafts as well as transmission housings – ideal for the application of PCD and CBN tools. Fine machining: Slide valve...

Open the catalog to page 11

The PCD tool program Standard and highly complex special tools uhring‘s PCD tool range on the one hand includes drills, milling cutters and reamers as well as interchangeable inserts. In addition, Guhring develops, designs and produces predominantly A small selection from our PCD tool program customer specific special tools for highly complex machining tasks. This includes, for example, PCDtipped finishing reamers for the machining of valve seats in the automotive industry or combination tools enabling different machining operations with one single tool.

Open the catalog to page 12

The CBN tool program Standard and highly complex special tools uhring‘s CBN tool range includes, dependent on the range of application, drills, milling cutters, reamers and interchangeable inserts. These tools are applied in the automotive and medical industry as well as other specific applications. For example, CBN tools from Guhring are successfully and economically applied in the production of wheels, pumps and shafts. A small selection from our CBN tool program

Open the catalog to page 13

Process design for optimal results The machining process should be observed in its entirety o take full advantage of the efficiency of PCD and CBN tools, the complete machining process should be looked at. This applies to the application of complex special solutions combining several machining steps in one tool. From process design to the application of the tool in volume production, Guhring‘s complete know-how is available to the 1. Tool design and imperfection inspection. customer. World-wide, Guhring‘s technical field service engineers for PCD and CBN tools provide advice to customers...

Open the catalog to page 14All GÜHRING catalogs and technical brochures

-

AEROSPACE

4 Pages

-

the best cast

36 Pages

-

DRILLING TOOLS

910 Pages

-

Grooving Systems

112 Pages

-

SuperLine 2016

148 Pages

-

GE 100 Floating holder

4 Pages

-

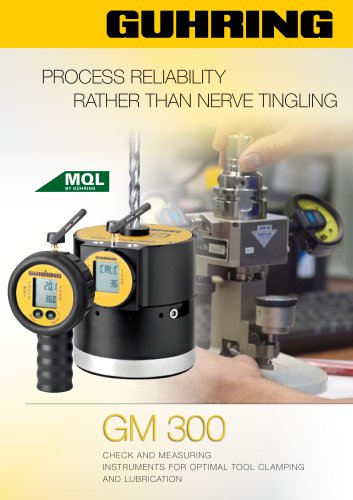

GM300_2015

228 Pages

-

GSS3001

5 Pages

-

Guhring Tool holders

4 Pages

-

GM 300 - MQL-Program

56 Pages

-

HMC 3000

6 Pages

-

TSG 3000

8 Pages

-

GSS 2000

12 Pages

-

PCD-Highlights AMB 2014

2 Pages

-

Stainless steels

18 Pages

-

Tools for the mould and die industry

112 Pages

-

Turbochargers PR 1000 M

6 Pages

-

PCD/CBNTechnology

153 Pages

-

MILLING TOOLS - 2014

332 Pages

-

CONVENTIONAL gun drills

60 Pages