Catalog excerpts

Induction Shrink Fit Systems GÜHRING - your world-wide PARTNER World-Wide Partner

Open the catalog to page 1

Work easily, quickly and efficiently ... The advantages of shrink fit technology: Perfect 360º tool clamping provides extreme clamping force and rigidity High repeatability, hence reduced operating errors Minimal imbalance thanks to rotational symmetry Excellent concentricity Reduced components, therefore lower costs for purchasing, storage and administration You benefit from: High economical efficiency Longer tool life Considerable time saving Safe shrink fitting The minimal heating of the shrink fit chuck ensures maximum operating safety on the one hand, on the other the controlled...

Open the catalog to page 2

Simple operation Quick cooling The movement of the spindle and its heating is a single handed operation. Tool clamping cannot be simpler and quicker! The water-cooled cooling elements cool down the shrink fit chuck quickly and safely. The shrink fit chuck remains clean and dry, so that it can be applied again without drying and without rusting. Hot spots remain safely screened during the cooling process in order to prevent burns. Efficient operation The turntable allows simultaneous preparation, heating and cooling of the shrink fit chucks. Subsequently, there is no waiting time, tool...

Open the catalog to page 3

Comfort Plus With turntable. The GSS 2000 Comfort Plus is the complete solution for simple, quick and secure tool clamping in the shrink fit chuck. ta tion Three s system At three positions you can simultaneously prepare, heat and cool – i.e. continuously clamp or unclamp tools. This gives your production maximum flexibility and efficiency, saving time and money.

Open the catalog to page 4

Put an end to complex tool clamping and adjustment. With GSS 2000 you can clamp your tools easily, quickly and securely. Benefit from the advantages of GSS 2000: > high-performance > overheating spindle, hence quick change time mode possible (equipment automatically selects the correct heating program) detection choosing wrong chuck/program programs for standard/reinforced and very small holder/shrink fit extensions > heating cutting rates

Open the catalog to page 5

Full performance The GSS 2000 Eco Plus is a single-position system that provides the full induction and cooling performance of a professional system at a reasonable cost. It is ideal as either an entry-level model that any time can be extended up to the equipment features of the Comfort Plus or used as a second or third system in your production.

Open the catalog to page 6

For a rters new st cooling without Reduced to the essentials For newcomers to the shrink fit technology the GSS 2000 offers all necessary equipment features for clamping or unclamping tools, but dispenses with the cooling.

Open the catalog to page 7

Swivel tray The practical swivel tray can be directly located within the GSS 2000 to accommodate the most important accessories. The sturdy trolley provides the GSS 2000 with secure positioning and location for the SpeedCooler. The spacious drawer of the trolley provides additional room for further accessories. As a result, everything is in its place.

Open the catalog to page 8

3 Pliers For the safe handling of hot tools. thermo secure Gold 3000 Perfect combination: GSS 2000 + TSG 3000 perfect concentricity highest balance maximum operational safety

Open the catalog to page 9

Comfort Plus Basic unit and accessories Test our Comfort Plus for 4 weeks free of charge ❏ System trolley 4748 1.000 ❏ Pliers 4749 1.000 ❏ Swivel trays 4763 1.000 appropriate holders Are tool diameters 3-5 mm applied? Company stamp: Telephone/fax: Contact name:

Open the catalog to page 10

Eco plus / Basic Basic unit and accessories ❏ GSS 2000 Eco Plus ❏ GSS 2000 Basic 4752 10.000 4730 10.000 ❏ System trolley ❏ Pliers 4749 1.000 ❏ Swivel trays 4763 1.000 appropriate holders Are tool diameters 3-5 mm applied? Company stamp: Telephone/fax: Contact name:

Open the catalog to page 11

Special tooling solutions Tapping/thread milling/ fluteless tapping Countersinking/ de-burring Modular tooling systems Gühring oHG Postfach 100247 • 72423 Albstadt Herderstraße 50-54 • 72458 Albstadt Tool restoration service Your contact: Mathias Hirt Product Manager Shrink Fit Systems No liability can be accepted for printing errors or technical changes of any kind. Our Conditions of Sale and Terms of Payment apply. Available on request. The illustrations show optional equipment.

Open the catalog to page 12All GÜHRING catalogs and technical brochures

-

AEROSPACE

4 Pages

-

the best cast

36 Pages

-

DRILLING TOOLS

910 Pages

-

Grooving Systems

112 Pages

-

SuperLine 2016

148 Pages

-

GE 100 Floating holder

4 Pages

-

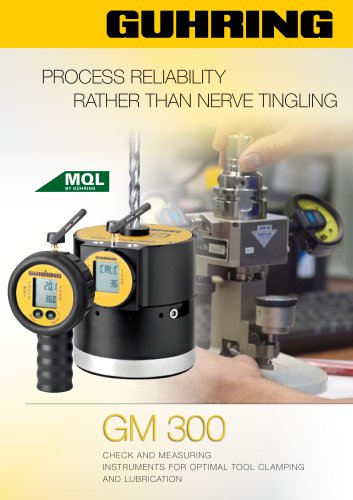

GM300_2015

228 Pages

-

GSS3001

5 Pages

-

Guhring Tool holders

4 Pages

-

GM 300 - MQL-Program

56 Pages

-

HMC 3000

6 Pages

-

TSG 3000

8 Pages

-

PCD and CBN tools

20 Pages

-

PCD-Highlights AMB 2014

2 Pages

-

Stainless steels

18 Pages

-

Tools for the mould and die industry

112 Pages

-

Turbochargers PR 1000 M

6 Pages

-

PCD/CBNTechnology

153 Pages

-

MILLING TOOLS - 2014

332 Pages

-

CONVENTIONAL gun drills

60 Pages