Catalog excerpts

Internal threading Special tools

Open the catalog to page 1

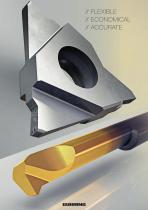

// FLEXIBLE // ECONOMICAL // ACCURATE

Open the catalog to page 2

GROOViNG SYSTEMS

Open the catalog to page 3

GROOVING SYSTEMS highest quality and flexibility thanks to maximum manufacturing depth GRINDING – INDEXABLE INSERTS AND CUTTING INSERTS Complete production on Guhring built grinding machines COATING – INDEXABLE INSERTS AND CUTTING INSERTS // In-house coating on Guhring built coating systems // Latest coating technology and coating ty

Open the catalog to page 4

MILLING/TURNING – HOLDER PRODUCTION GUHRING’S OWN CARBIDE PRODUCTION Blanks – Indexable inserts and cutting inserts Guhring own carbide gra

Open the catalog to page 5

Guhring R&D for innovative tool developments Highest quality standard world-wide Pooled expertise under one roof Exceptionally high manufacturing depth Machining technology with an edge GUHRING Production location Grooving tools

Open the catalog to page 6

Dr. Jorg Guhring President Oliver Guhring Sales and Marketing Director Internal training and further programme of education Employees world-wide Employees Germany « International knowledge transfer thanks to world-wide exchange programme for employees

Open the catalog to page 8

Dietmar Pfranger Bernd Schatz R&D, Logistics, Technical and Financial and Commercial Production Director Director

Open the catalog to page 9

Everything from one supplier – comprehensive and global With a global network of manufacturing sites Guhring develops and produces precision tools for all the important markets. Users from the automotive industry, the aerospace industry or the machine tool and general industry rely on the trend-setting tools manufactured world-wide at the highest level to uniform quality standards. PRODUCTION CENTRES SERVICE CENTRES GREAT BRITAIN Guhring Corp. sales@guhring.com www.guhring.com BROOKFIELD Guhring Inc. sales@guhring.com www.guhring.com NEW HUDSON Guhring Inc. sales@guhring.com www.guhring.com...

Open the catalog to page 10

With innovative technologies Guhring meets specific customer requirements from process proposal to series application of the precision tools – flexibly, promptly, globally. For this, experts are in action internationally looking after customers on site. Production, service and contact persons are available from one supplier world-wide. Own machine construction Highest quality standards world-wide CZECH REPUBLIC Dr. Gühring KG info@guehring.de www.guehring.de Gühring KG info@guehring.de www.guehring.de FACTORY 1 Dr. Gühring KG info@guehring.de www.guehring.de G-Elit Präzisionswerkzeuge...

Open the catalog to page 11

GROOVING SYSTEMS Highest quality and flexibility thanks to maximum manufacturing depth. All from one supplier.

Open the catalog to page 12

SYSTEM 104 Micro-precision tools from Ø 0.7 mm

Open the catalog to page 13

SYSTEM OVERVIEW STEM 1 4MICRO-PRECISION TOOLS Round shank clamping screw top page 16 Round shank clamping screw lateral page 17 Square shank clamping screw lateral page 18 Round shank broaching page 48 Boring out Back boring Boring out and profiling and profiling and chamfering from page 20 from page 31 page 33 Internal grooving, Internal grooving, straight slots full radius slots Internal grooving and chamfering page 37 Internal threading Axial grooving bores Axial chamfering bores from page 43 from page 38 page 42 Cutting inserts from hole-0 0.7 mm...

Open the catalog to page 15

TOOL HOLDER FOR MICRO-PRECISION TOOLS Round shank holder, clamping screw top • Shank-0 10-25, for cutting insert type 104 Type GB 104 • with internal coolant delivery -

Open the catalog to page 16

Round shank holder, clamping screw lateral • Shank-0 10-25, for cutting insert type 104 Type GB 104 • with internal coolant delivery -

Open the catalog to page 17

TOOL HOLDER FOR MICRO-PRECISION TOOLS Square shank holder, 90° offset • Shank 10x10 - 16x16, for cutting insert type 104 • without internal coolant delivery

Open the catalog to page 18

MICRO-PRECISION TOOLS FOR TURNINGCutting insert for boring out and profiling Tool material Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94 Right hand version shown Left hand version mirror image Cutting direction

Open the catalog to page 20

Cutting direction

Open the catalog to page 21

Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94

Open the catalog to page 22

Cutting direction

Open the catalog to page 23

Cutting insert for boring out and profiling Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94

Open the catalog to page 24

Cutting direction ^ ^ ^ |T)]

Open the catalog to page 25

Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94 Right hand version shown Left hand version mirror image

Open the catalog to page 26

Cutting direction ^ ^ ^ |T)]

Open the catalog to page 27

Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94

Open the catalog to page 28

Cutting direction ^ ^ ^ |T)]

Open the catalog to page 29

Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94

Open the catalog to page 30

Cutting insert for back boring and profiling Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94

Open the catalog to page 31

Cutting direction ^ ^ ^ |T)]

Open the catalog to page 32

Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94

Open the catalog to page 33

MICRO-PRECISION TOOLS FOR RADIAL GROOVINGCutting insert for internal grooving, straight slots System 104 from hole-0 1, grooving depth up to 1 mm Tool material Solid carbide for tool holders type GH104/GB104 see from page 16 GiiHHINGNAVIGATOR Cutting data page 94

Open the catalog to page 34

Cutting direction ^ ^ ^ |T)]

Open the catalog to page 35

Cutting insert for internal grooving, full radius slots • from hole-0 3, full radius R0.4-R0.58 Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94

Open the catalog to page 36

Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94 Right hand version shown Left hand version mirror image Cutting direction

Open the catalog to page 37

Cutting insert for axial grooving bores, straight slots from hole-0 4, grooving depth up to 5 mm Tool material Type Surface Solid carbide for tool holders type GH104/GB104 see from page 16 GUHHINGNAVIGATOR Cutting data page 94

Open the catalog to page 38All GÜHRING catalogs and technical brochures

-

AEROSPACE

4 Pages

-

the best cast

36 Pages

-

DRILLING TOOLS

910 Pages

-

SuperLine 2016

148 Pages

-

GE 100 Floating holder

4 Pages

-

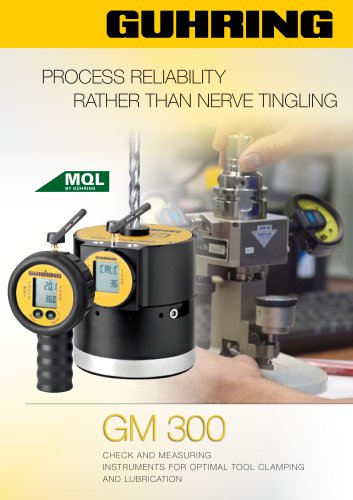

GM300_2015

228 Pages

-

GSS3001

5 Pages

-

Guhring Tool holders

4 Pages

-

GM 300 - MQL-Program

56 Pages

-

HMC 3000

6 Pages

-

TSG 3000

8 Pages

-

GSS 2000

12 Pages

-

PCD and CBN tools

20 Pages

-

PCD-Highlights AMB 2014

2 Pages

-

Stainless steels

18 Pages

-

Tools for the mould and die industry

112 Pages

-

Turbochargers PR 1000 M

6 Pages

-

PCD/CBNTechnology

153 Pages

-

MILLING TOOLS - 2014

332 Pages

-

CONVENTIONAL gun drills

60 Pages