Website:

GÜHRING

Website:

GÜHRING

Catalog excerpts

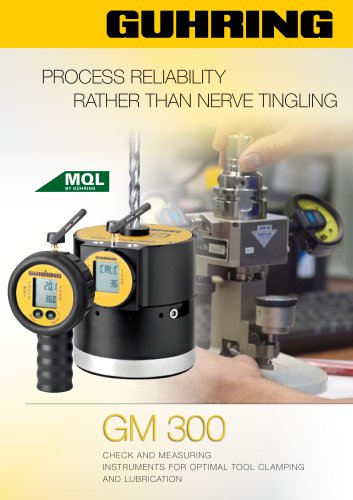

PROCESS RELIABILITY RATHER THAN NERVE TINGLING

Open the catalog to page 1

Check- and Measuring instruments Optimal tool clamping and lubrication Pre-requisite for perfect machining results is not only the right choice of machine, tool holder, chuck and tool. Just as important is a constant check of tool clamping and lubrication. Optimal tool clamping and lubrication ensures long tool life, highest cutting performance as well as excellent quality and prevents tool breakage, chip congestion or inferior machining quality. As a full-range supplier of tools, tool holders and chucks for all matters machining, Guhring has also developed a comprehensive program of...

Open the catalog to page 2

GUHRING REPAIR SERVICE clamping force for hydraulic chucks The hydraulic clamping technology is a well-known, proven and reliable method for the clamping of tools. Thanks to its completely closed design the system is sealed and impervious, requires extremely low maintenance and guarantees longevity. Following many years of general use, however, thermal and mechanical influences can lead to a reduction in clamping force. The result can be a poor tool life and a diminished surface quality including expensive tool breakages during machining operations. Determining the loss of clamping force...

Open the catalog to page 3

Senso-shrink 3000 clamping force for shrink fit chucks SENSO-SHRINK 3000 offers the user the following benefits: With SENSO-SHRINK 3000 Guhring offers a clamping force measuring instrument for shrink fit chucks. SENSO-SHRINK 3000 simply, quickly and accurately determines the clamping force of the shrink fit chuck by measuring the bore volume on your premises. The measuring result displayed by SENSO SHRINK 3000 is the deviation percentage from the nominal value of a reference chuck. Measuring results in a range between 95 % and 105 % indicate optimal clamping of the tool. simple, quick and...

Open the catalog to page 4

filtering efficiency of the coolant system Coolant pressure and volume Guhring‘s PQ 3000 enables quick and simple measuring of pressure and volume of coolant flow directly in the machine using the actual tool applied. in the stationary tool spindle. This way, it is possible to establish the real conditions of the relevant machine and tool configuration and measure the resulting actual rate of flow. Guhring has developed the PQ 3000 instrument for quick, simple and direct measuring of the existing coolant pressure and rate of flow for tools with internal cooling. PQ 3000 provides the...

Open the catalog to page 5

MQL-Check 3000 coolant volume and reaction time with MQL The development of Guhring‘s new MQL-Check 3000 allows simple and quick measuring of the coolant volume and the reaction time with minimal quantity lubrication (MQL) directly at the tool point. For the user, the result is a considerable increase in process reliability with MQL machining. MQL-Check 3000 consists of: measuring unit incl. sender and magnetic base for installation with horizontal machining BY GÜHRING display facility with receiver measuring filter for measuring range up to 12 ml/h, up to 30 ml/h and up to 60 ml/h Data...

Open the catalog to page 6

Special tooling solutions Tapping/thread milling/ fluteless tapping Countersinking/ de-burring Modular tooling systems Tool restoration service No liability can be accepted for printing errors or technical changes of any kind. The illustrations show optional equipment. Our Conditions of Sale and Terms of Payment apply. Available on request.

Open the catalog to page 7All GÜHRING catalogs and technical brochures

-

AEROSPACE

4 Pages

-

the best cast

36 Pages

-

DRILLING TOOLS

910 Pages

-

Grooving Systems

112 Pages

-

SuperLine 2016

148 Pages

-

GE 100 Floating holder

4 Pages

-

GM300_2015

228 Pages

-

GSS3001

5 Pages

-

Guhring Tool holders

4 Pages

-

GM 300 - MQL-Program

56 Pages

-

HMC 3000

6 Pages

-

TSG 3000

8 Pages

-

GSS 2000

12 Pages

-

PCD and CBN tools

20 Pages

-

PCD-Highlights AMB 2014

2 Pages

-

Stainless steels

18 Pages

-

Tools for the mould and die industry

112 Pages

-

Turbochargers PR 1000 M

6 Pages

-

PCD/CBNTechnology

153 Pages

-

MILLING TOOLS - 2014

332 Pages

-

CONVENTIONAL gun drills

60 Pages