Catalog excerpts

DRILLING TOOLS

Open the catalog to page 1

Oliver Gühring Sales and Marketing Director Internal training and further programme of education Employees world-wide Employees Germany International knowledge transfer thanks to world-wide exchange programme for employees

Open the catalog to page 2

Dietmar Pfränger Bernd Schatz R&D, Logistics, Technical and Production Director Financial and Commercial Director Core segment tools Tool types Standard tools Special tools

Open the catalog to page 3

TOOL MATERIALS Own carbide production Optimal co-ordination of all tool parameters thanks to own R&D sectors MACHINE & EQUIPMENT DIVISION Own machine tool and equipment divisions

Open the catalog to page 4

GEOMETRIES Own R&D for tool development COATINGS Own coating systems and own coating development

Open the catalog to page 5

Everything from one supplier – comprehensive and global With a global network of manufacturing sites Guhring develops and produces precision tools for all the important markets. Users from the automotive industry, the aerospace industry or the machine tool and general industry rely on the trend-setting tools manufactured world-wide at the highest level to uniform quality standards. MORE THAN PRODUCTION AND SERVICE CENTRES Guhring Corp. sales@guhring.com www.guhring.com Guhring Sweden AB info@guehring.se www.guehring.se HEADQUARTER Gühring KG info@guehring.de www.guehring.de Gühring KG...

Open the catalog to page 6

With innovative technologies Guhring meets specific customer requirements from process proposal to series application of the precision tools – flexibly, promptly, globally. For this, experts are in action internationally looking after customers on site. Production, service and contact persons are available from one supplier world-wide. Highest quality standards world-wide Dr. Gühring KG info@guehring.de www.guehring.de G-Elit Präzisionswerkzeuge info@guehring.de www.guehring.de Gühring s.r.l.-Romania romania@guehring.de Guhring Vietnam LLC info@guhring.vn Guhring Pty. Ltd....

Open the catalog to page 7

Everything from ONE SUPPLIER Our variety of drills includes micro-precision drills Ø 0.05 mm, special solutions Ø 180 mm and HSS as well as solid carbide, 50,000 products for every application. SOLID CARBIDE RATIO DRILLS from page 3 HT 800 INTERCHANGEABLE INSERT DRILLING SYSTEM from page 123 HSS/HSCO TWIST DRILLS straight shank Morse taper shank from page 175, 435

Open the catalog to page 8

GUN DRILLS single-fluted and two-fluted gun drills spiral deep hole drills from page 515 MICRO-PRECISION DRILLS SOLID CARBIDE + HSSE NC SPOTTING DRILLS & CENTRE DRILLS from page 665 STEP DRILLS & CORE DRILLS from page 71

Open the catalog to page 9

e a rc h , n in res ctio ation. n. Per fe ur aspir novatio n - is o ever y in er fectio ard with hining p e stand re . M a c sets th nufactu to o l m a Guhring ent and velopm de Y UALIT F STEEL Q EMIUM HINING O PR C HE MA IN T RT 100 S // steel optimized micro-geometry // high cutting parameters // consistent long tool life from page 59, 96

Open the catalog to page 10

OPTIMISED DRILL CORE heavily reduced tapered core for additional tool stability whilst simultaneously minimising forces AeroX // HSCO8 twist drills for assembly work in general or high-alloyed materials, titanium and aluminium materials // quick drill advance thanks to optimized 135º split point from page 313 For maximum wear and heat resistance // maximum performance especially with high-alloyed and high tensile steels and special alloys // robust design thanks to rigid core, 135º split point geometry from page 31

Open the catalog to page 11

HSS coolant duct drills // for the machining of steel beams and in unstable conditions // optimal cooling with axial and radial coolant delivery // minimum burr development from page 499 we b th i nn ing SIRIUS-coating for maximum performance especially with stainless steels VA-HSCO Sirius twist drills // longer tool life thanks to the Sirius-coating’s high wear resistance combined with an optimized 130º split point geometry from page 231

Open the catalog to page 12

HSCO NC spotting drills ting e RE-coaand heat resistanc FI ano ating -co E with NanoFIRE-coating // accurate spotting with maximum cutting values and tool life // maximum performance thanks to nanoFire-coating from page 705 EB800 guide pads and inserts with new coating // optimal adaption to the material to be machined thanks different coating options from page 556

Open the catalog to page 13

esses. n g p ro c h inin machin e s e a rc etting r ressive t re n d - s ire prog ip with ls requ h ria leaders r t m a te . nology f-the-a g tools te c h S t a te - o y cuttin re s t h e r secu f o r ro t a Guhring ncepts ntive co nd inve a N DESIG g ATIVE t coolin N N OV I icien o re e f f for m // optimised flow velocity // especially suitable for the machining of stainless steels, titanium- and special alloys // increased coolant volume

Open the catalog to page 14

NT FFICIE LY E M I CA L m a t e r i a l s NO E ECO aluminium MOR of ILLING DR // entire material range of soft and tough aluminium found in both wrought and cast alloys. // special drills for Ø 3 mm to 20 mm and depths up to 12xD // wet machining and MQL possible from page 815 // especially suitable for the machining of long-chipping steels // excellent chip evacuation even with reduced cutting speeds // flute form and cutting edge geometry optimally adapted to the machining task

Open the catalog to page 15

ICS PLAST ive materials SITE OMPO r highly abras C FIBRE s fo solution to o l i n g MACHINING OF FCP Optimised tools for the machining of glass fibre reinforced plastics (GFRP) and carbon fibre reinforced plastics (CFRP) as well as stack materials components without fibre projections delamination-free component surface no damage to component through “peel-up” or “push out” prevention of fibre splitting “pull-out” on component minimising burr development prevention of thermal damage from page 816 FCP DRILLING OPERATION with optimal mac

Open the catalog to page 16

tion ptimisa ife o E to o l l C ation EARAN rg e t l o c to t a D CL CTURE tion guidance TRU SER S oling lubrica LA co a n k s to th // reduction of thermal stresses, i.e. at outer corners and cutting lips // improved cooling lubrication // increased hole quality // high design flexibility of clearance thanks to laser machining simulation with Computational Fluid Dynamics (CFD) Tool axis // more favourable chip development/improved chip fracture // improved chip evacuation // production of nominal fracture points in chip // reduced built-up edge // lower machining forces and Cutting edge 1...

Open the catalog to page 17All GÜHRING catalogs and technical brochures

-

AEROSPACE

4 Pages

-

the best cast

36 Pages

-

Grooving Systems

112 Pages

-

SuperLine 2016

148 Pages

-

GE 100 Floating holder

4 Pages

-

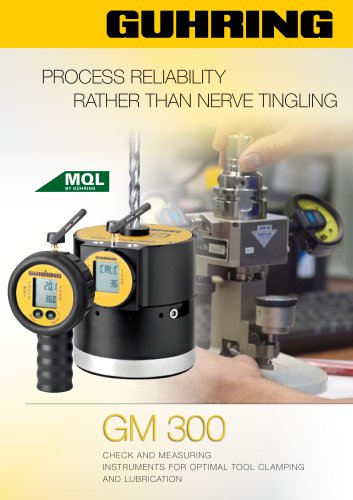

GM300_2015

228 Pages

-

GSS3001

5 Pages

-

Guhring Tool holders

4 Pages

-

GM 300 - MQL-Program

56 Pages

-

HMC 3000

6 Pages

-

TSG 3000

8 Pages

-

GSS 2000

12 Pages

-

PCD and CBN tools

20 Pages

-

PCD-Highlights AMB 2014

2 Pages

-

Stainless steels

18 Pages

-

Tools for the mould and die industry

112 Pages

-

Turbochargers PR 1000 M

6 Pages

-

PCD/CBNTechnology

153 Pages

-

MILLING TOOLS - 2014

332 Pages

-

CONVENTIONAL gun drills

60 Pages