Catalog excerpts

115 998/0653-V-22 The image on the front cover printed with kind permission of Böhler-Uddeholm GUhring TOOLS fOr THE CompletE MACHINING OF CAST MATERIALS

Open the catalog to page 1

■ THE BEST CAST Especially in the automotive industry, but also in many other industrial sectors, the machining of cast iron is one of the most widespread and multi-faceted machining tasks. It ranges from machining conventional cast materials such as grey cast iron to the demanding new materials such as CGI (compacted graphite iron). At the same time, the user is making highest demands on accuracy and quality. For this most versatile of applications, Guhring supplies tools for every machining task including drilling, tapping and reaming as well as milling operations providing the customer...

Open the catalog to page 2

TWO-FLUTE GUN DRILLS ZB 80 Type Program page Solid carbide Solid carbide Solid carbide Solid carbide Solid carbide Thread cutting tools m7 Guhring no. Standard Tool material Carbide grade Surface finish Type Cutting direction Tolerance on diameter Discount group Guhring standard Solid carbide Solid carbide Solid carbide Solid carbide Q bright (S) TiN 0 FIRE Q TiAIN

Open the catalog to page 3

SINGLE-FLUTE GUN DRILLS EB 100 TWO-FLUTE GUN DRILLS ZB 80 FOR THE MACHINING OF CAST IRON Drilling depth <35xd <35xd No. of flutes Tool material Carbide grade Guhring description Surface finish Cooling Guhring no. Flute length ex-stock special tools Material group Cast iron Solid carbide Solid carbide Material examples Figures in bold = material no. to DIN EN The feed column nos. always relate to tools with the recommended coating. n some cases, the successful application of un-coated tools cannot be guaranteed. un drills must be guided during spot drilling. Gun drills must never operate at...

Open the catalog to page 4

Contents Standard Type GuringCutting Tool Surface Tolerance on Guhring Discount Program guide direction material finish diameter no. group page page Tool description Solid carbide Solid carbide Solid carbide Solid carbide Solid carbide Solid carbide Solid carbide Solid carbide Solid carbide Solid carbide Solid carbide

Open the catalog to page 5

Ratio oil feed drills 1. operation: drilling with Ratio drills ...

Open the catalog to page 6

Ratio drill type RT 100 R Information the high-performance drill for all cast iron materials Thanks to the big success in the special tool sector, Ratio drills type RT 100 R with the patent applied radius geometry are now part of a comprehensive standard range. The tools were primarily developed for the efficient machining of the new materials CGI and ADI, however, they also offer a considerable saving potential for conventional cast materials such as grey cast iron, spheroidal graphite and malleable cast iron. Thanks to the exceptional tool life combined with high cutting rates the...

Open the catalog to page 7

Guhring no. Standard Tool material Carbide grade Surface finish Type Drilling depth Cutting direction Tolerance on diameter Discount group Guhring standard Solid carbide Solid carbide

Open the catalog to page 8

Guhring no. Standard Tool material Carbide grade Surface finish Type Drilling depth Cutting direction Tolerance on diameter Discount group Guhring standard Solid carbide Solid carbide Availability GUHHING

Open the catalog to page 9

Ratio oil feed drills RT 100 R Guhring no. Guhring standard Tool material Solid carbide Solid carbide Carbide grade Surface finish Type Drilling depth Cutting direction Discount group

Open the catalog to page 10

Guhring no. Standard Tool material Carbide grade Surface finish Type Drilling depth Cutting direction Tolerance on diameter Discount group Guhring standard Solid carbide Solid carbide

Open the catalog to page 11

Guhring no. Standard Tool material Carbide grade Surface finish Type Drilling depth Cutting direction Tolerance on diameter Discount group Guhring standard Solid carbide Solid carbide

Open the catalog to page 12

Guhring no. Standard Tool material Carbide grade Surface finish Type Drilling depth Cutting direction Tolerance on diameter Discount group

Open the catalog to page 13

Guhring no. Standard Tool material Carbide grade Surface finish Type Drilling depth Cutting direction Tolerance on diameter Discount group

Open the catalog to page 14

Guhring no. Standard Tool material Carbide grade Surface finish Type Drilling depth Cutting direction Tolerance on diameter Discount group

Open the catalog to page 15

RATiO OIL FEED DRILLS RT 100 R Tool material Carbide grade Type Surface finish _Cooling Material group Material examples Figures in bold = material no. to DIN EN Solid carbide Cast iron Spheroidal graphite and malleable cast iron pre-conditions for use: Powerful machines, no play in spindle bearings, alignment accurate tool holders, Maximum concentricity error of clamped tools: 0.02 mm. High coolant pressure. We recommend the application of hydraulic chucks or shrink fit chucks. Cooling: We recommend cooling with soluble oil or neat oil. Under certain conditions RT 100 R can also be applied...

Open the catalog to page 16

RATiO OIL FEED DRILLS RT 150 GG Tool material Carbide grade Type Surface finish _Cooling |Guh.no./std. HA Material group Material examples Figures in bold = material no. to DIN EN Hardness vc m/min Solid carbide <240 HB <300 HB pre-conditions for use: Powerful machines, no play in spindle bearings, alignment accurate tool holders, Maximum concentricity error of clamped tools: 0.02 mm. High coolant pressure. We recommend the application of hydraulic chucks or shrink fit chucks. Cooling: We recommend cooling with soluble oil or neat oil.

Open the catalog to page 17

OiL FEED TAPS, FLUTELESS TAPS & THREAD MiLLiNG CUTTERS 2. OPERATiON: MACHiNiNG The wORKpiECE wITH taps, fluteless taps & thread milling cutters TYPE DTMC SP THREAD MILLING CUTTER TYPE TMU SP THREAD MILLIN CUTTER

Open the catalog to page 18

Guhring no. Standard 1 Standard 2 Tool material Surface finish Type Form Cutting direction Tolerance on diameter Discount group

Open the catalog to page 19

Guhring no. Standard 1 Standard 2 Tool material Surface finish Type Form Cutting direction Tolerance on diameter Discount group Solid carbide FLUTELESS TAPS FOR MALLEABLE CAST MATERiALS In addition to solid carbide oil feed fluteless taps for ISO-metric fine threads, Guhring no. 1581, our H standard range also includes the following fluteless taps optimised for the machining of malleable cast materials: Solid carbide oil feed fluteless taps for ISO-metric threads with TiN-coating, to DIN 371, for M3 to M10 threads, Guhring no. 1972. Solid carbide oil feed fluteless taps for...

Open the catalog to page 20All GÜHRING catalogs and technical brochures

-

AEROSPACE

4 Pages

-

DRILLING TOOLS

910 Pages

-

Grooving Systems

112 Pages

-

SuperLine 2016

148 Pages

-

GE 100 Floating holder

4 Pages

-

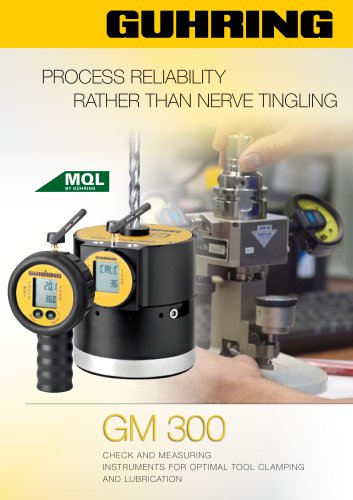

GM300_2015

228 Pages

-

GSS3001

5 Pages

-

Guhring Tool holders

4 Pages

-

GM 300 - MQL-Program

56 Pages

-

HMC 3000

6 Pages

-

TSG 3000

8 Pages

-

GSS 2000

12 Pages

-

PCD and CBN tools

20 Pages

-

PCD-Highlights AMB 2014

2 Pages

-

Stainless steels

18 Pages

-

Tools for the mould and die industry

112 Pages

-

Turbochargers PR 1000 M

6 Pages

-

PCD/CBNTechnology

153 Pages

-

MILLING TOOLS - 2014

332 Pages

-

CONVENTIONAL gun drills

60 Pages