Catalog excerpts

Testing requirements:After the battery is fully charged according to the specified test method, the battery is placed on the wire mesh of the test tool, and the test tooling is shown in Appendix E.2. If the battery slips during the test, the battery sample can be fixed to the wire mesh with a single wire; if this is not the case, the battery cannot be bundled. Heat the battery with flame and stop heating when the following three conditions occur: a) battery explosion b) The battery is completely burned c) continuous heating for 30min, but the battery is not ignited, not exploding

Open the catalog to page 1

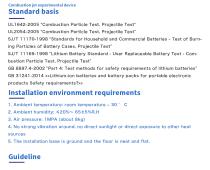

Combustion jet experimental device ULl 642-2005 "Combustion Particle Test, Projectile Test" UL2054-2005 "Combustion Particle Test, Projectile Test" SJ/T 1 1 170-1998 "Standards for Household and Commercial Batteries - Test of Burning Particles of Battery Cases, Projectile Test" SJ/T 1 1 1 69-1 998 "Lithium Battery Standard - User Replaceable Battery Test - Combustion Particle Test, Projectile Test" GB 8897.4-2002 "Part 4: Test methods for safety requirements of lithium batteries" GB 31 241-2014 «Lithium-ion batteries and battery packs for portable electronic products Safety requirements?»...

Open the catalog to page 3

Standard IJ/T11170-1998 Household and Commercial Battery Safety Standards Combustion particle test: Requirement: Each test sample cell or battery is placed on a wire mesh screen. The mesh screen has 20 holes per 25.4 mn (1 inch) and the wire diameter is 0.43 mn (0.017 inch). The mesh screen was installed at 38.1 mn (1.5 inches) above the burner. The ratio of combustion to air flow is adjusted to produce a bright blue flame that causes the wire mesh to glow into a bright red color. A multi-layered gauze is placed vertically with a distance of 0.94 m (3 ft) from the center of the mesh to the...

Open the catalog to page 4

SJ/T 11169-1998 lithium battery standard UL 1642: 1995 Combustion particle test: Requirement: For protection, this test is to be carried out in a room separate from the observer. Each test sample cell or battery was placed on a wire mesh screen. The mesh screen had 20 holes per 25.4 mm (1 inch) and the wire diameter was 0.43 mm (0.017 inches). The mesh screen was installed at 38.1 mm (1.5 inches) above the burner. The ratio of burning to air flow is adjusted to produce a bright blue flame that causes the wire mesh to glow into a bright red color. It is approximately 700° (1292° F). A...

Open the catalog to page 5

Combustion jet test Requirement: Each battery tested was placed on a wire screen with a hole density of 20/inch (25.4 mn) and the wire diameter was 0.017 inches (0.43 mn). The steel screen is placed directly above the combustion hole, lAl/2 inch (38.1mn) from the hole. The fuel gas supply requires that a bright blue flame be placed directly on the steel screen to make it bright red. A vertical panel is placed 3 feet (0.31 m) from the center of the steel screen, and the panel is naturally (easy to burn) hang the cotton layer. The cotton area is 1 square yard (914 x 914mn), a total of four...

Open the catalog to page 6

Combustion jet test Requirement: Each test cell is placed on a 20-hole steel wire per inch (25.4 mm) with a wire thickness of 0.017 inches. The screen is placed at a distance of 1-1/2 (58.1 mm) inches from the burner. Fuel and air are sprayed at a speed that provides a bright blue flame so that the wire mesh burns bright red. A coarse asbestos panel was placed at a vertical distance of 3 feet (0.91 m) from the center of the stencil. The asbestos sheet is one square yard and consists of four layers of coarse asbestos material weighing 0.4-0.6 ounces per square yard. The test sample is placed...

Open the catalog to page 7All Guangdong Jian Qiao Testing Equipment Co. catalogs and technical brochures

-

JQ-3F-1000

6 Pages

-

JQ-876

4 Pages

-

JQ-264A

6 Pages

-

JQTHV-1000B

7 Pages

-

JQTHV-1700

5 Pages

-

JQTS3-408

7 Pages

-

JQTS2-50

12 Pages

-

JQESS-225

8 Pages

-

JQT-720

4 Pages

-

JQTHV-3400

7 Pages

-

JQTHV-500

8 Pages

-

JQTHV-1000

5 Pages

-

Impact test bench IS-10

7 Pages

-

Impact test kit JQ18-1

2 Pages

-

Test Fixture

2 Pages

-

Workshop

3 Pages

-

SL0808

6 Pages

-

LIS50

2 Pages

-

JQA-202-335

9 Pages

-

JQA-102-240

8 Pages

-

JQA-021-150

8 Pages

-

JQA-031-150

7 Pages

-

Workshop

6 Pages

-

RLY-1000A

3 Pages

-

JQ-1000D

3 Pages

-

JQ-315ST

3 Pages

-

DL-6055

2 Pages

-

JYZC-20

6 Pages

-

DL-815

2 Pages

-

FZ-8201

3 Pages

-

JP-7006

4 Pages

-

DQY-5M3

2 Pages

-

JQ-12M3

3 Pages

-

JQ-5000A

3 Pages

-

HS-6053

3 Pages

-

JQ-8209-12

5 Pages

-

JY-100

5 Pages

-

JQ-8104

2 Pages

-

JQ-8226A

2 Pages

-

JQ-8106

2 Pages

-

JQ-8108

2 Pages

-

JQ-6052

5 Pages

-

JQ-8101

2 Pages

-

JQ-8103

3 Pages

-

JQ-8102

2 Pages

-

Electrodynamic shaker JS-50A

4 Pages

-

Pneumatic crash tester JQQ-50

12 Pages

-

Impact test bench JQJ-50

8 Pages

-

JIAN QIAO Adjustment device

2 Pages

-

Electrodynamic shaker

31 Pages

-

Battery testing chamber

28 Pages

-

climatic chambe catalogue

70 Pages