Catalog excerpts

Performance parameters Model Structure Horizontal Horizontal Horizontal Crush Mode Horizontal Horizontal Horizontal Drive Mode Electro-hydraulic servo Chamber Independent horizontal structure and control system Test Space W2500 X D2000 X H 1000mm [can be customized) Energy Saving Design PowerSupply Crush Speed Hail Penetration Speed Test Condition Adopt dual hydraulic cylinder driving, main-subsidiary hydraulic cylinder design. Maximized saving space and reduce the Iota! power configuration of the equipment, AC380V 50HZ 1 ‘-400rnm/min (Adjustable) 1 ~40mm/s (Adjustable] The variable of force, displacement, speed, time, auxiliary voltage, auxiliary temperature (.etc) can be used as control variable in naiE penetration and crush tests. Control Mode MCU+PC combined control mode, remote control operation to ensure the safety of testing. Punning Mode Available for Programming Mode and Constant Mode Hail Penetration Accuracy ^1%[F$R] Crush Deformation 0-100% multistage setting, multi-layer crush deformation loading available. Crush Fixture Arc crush plate ( Radius 75mm) , available for different fixtures according ta different test standards. Data Acquisition Module independent remote collection and isolation, Multiplex voltage, temperature, current acquisition channel, ensure the data correctly; Safety Alarm Device Electrical leakage, over voltage, overload and over temperature, over current protection, abnormal sound and light alarm, smoke alarm lamp, etc *FlQme resistance and explosion-proof design for the test area. Safety device *Ru$t-proof and anti-corrosion design for the lest area *Emergency stop button. *Over pressure protection *Crush limit protection device, *Water-proof for the test area. *Other safety design. Related Standard Test Requirements 1. Tost object: Battery storage pack or system. 2. Crush according to the following conditions 2.1 Crush plate: half cylinder with radius 75mm, length of the plate should be larger than the crushed battery size but shorter than 1 m; 2.2 Crush Direction: X and Y direction (car driving direction called X axis, another horizontal direction perpendicular to cor driving direction coiled Y axis). To ensure the safety of test operation, tests can be performed on two test objects separately. 2.3 Crush level: Stop the crush when the crush force reached 100KN or the crush deformed by 30% of the total size of the crush direction for the battery pack, remain for 1 Omins. 3. After testing, observe for 1 h under fhe testing temperature.

Open the catalog to page 1All Guangdong Bell Experiment Equipment Co. catalogs and technical brochures

-

Battery Safety Test Chamber C

28 Pages

-

Environmental Test Chamber C

14 Pages

-

Flammability tester FLAMMABE

1 Pages

-

Crush test chamber BE-8111

1 Pages

-

vacuum drying oven BE-ZK-M

1 Pages

-

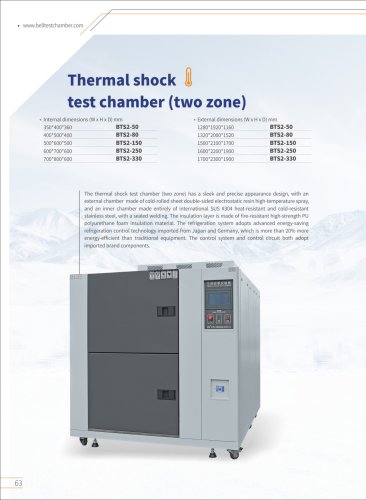

thermal shock test chamber

1 Pages

-

thermal shock test chamber

1 Pages

-

climate test chambers

1 Pages

-

Performance tester BE-8214

1 Pages

-

Dust test chamber BE-XR-12M³

1 Pages

-

Leak testing machine

1 Pages

-

Drop tester BE-8206-1500

1 Pages

-

Drop test chamber BE-8108

1 Pages

-

Flammability tester BE-8105

1 Pages

Archived catalogs

-

HAST test chamber BTH-1000D

1 Pages