Catalog excerpts

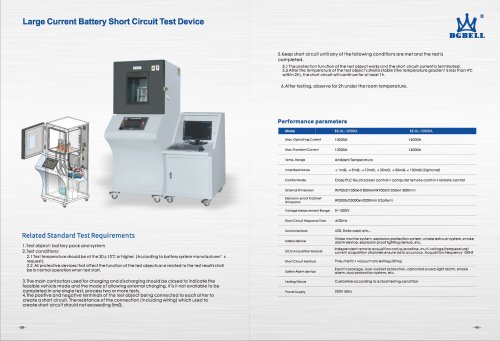

Large Current Battery Short Circuit Test chamber Large Current Battery Short Circuit Testing Machine Large Current Battery Short Circuit Tester Performance parameters Model BE-XL-10000A BE-XL-15000A Max. Operating Current 10000A 16000A Max. Transient Current Temp. Range Ambient Temperature Inner Resistance <1mΩ, <5mΩ, <10mΩ, <20mΩ, <50mΩ, <100mΩ (Optional) Control Mode Close PLC touch screen control + computer remote control + remote control External Dimension W700xD1050xH1830mmwW700xD1050xH1830mm Explosion-proof Cabinet Dimension W2000xD3000xH2000mm (Option) Voltage Measurement Range 0~1000V Short Circuit Response Time ≤20ms Data Interface USB, Data card, etc... Safety device Video monitor system, explosion protection system, smoke exhaust system, smoke alarm device, explosion proof lighting device, etc. Data Acquisition Module Independent remote acquisition and quarantine, multi-voltage/temperature/current acquisition channels ensure data accuracy. Acquisition frequency 100HZ Short Circuit Method Pneumatic + vacuum arc extinguishing Safety Alarm device Electric leakage, over-current protection, abnormal sound-light alarm, smoke alarm, dual protection system, etc. Testing Fixture Customize according to actual testing condition Power Supply 220V 50Hz Related Standard Test Requirements 1.Test object: battery pack and system 2. Test conditions: 2.1 Test temperature should be at the 20+ 10°C or higher. (According to battery system manufacturer’s request). 2.2 All protective devices that affect the function of the test objects and related to the test results shall be in normal operation when test start. 3.The main contactors used for charging and discharging should be closed to indicate the feasible vehicle mode and the mode of allowing external charging. If is it not available to be completed in one single test, process two or more tests. 4. The positive and negative terminals of the test object being connected to each other to create a short circuit. The resistance of the connection (including wiring) which used to create short circuit should not exceeding 5mΩ. 5.Keep short circuit until any of the following conditions are met and the test is completed. 5.1 The protection function of the test object works and the short circuit current is terminated. 5.2 After the temperature of the test object's shellis stable (the temperature gradient is less than 4°C within 2h), the short circuit will continue for at least 1h. 6.After testing, observe for 2h under the room temperatu

Open the catalog to page 1All Guangdong Bell Experiment Equipment Co. catalogs and technical brochures

-

Battery Safety Test Chamber C

28 Pages

-

Environmental Test Chamber C

14 Pages

-

Flammability tester FLAMMABE

1 Pages

-

Crush test chamber BE-8111

1 Pages

-

vacuum drying oven BE-ZK-M

1 Pages

-

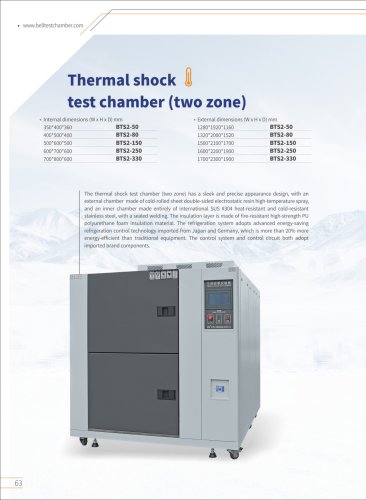

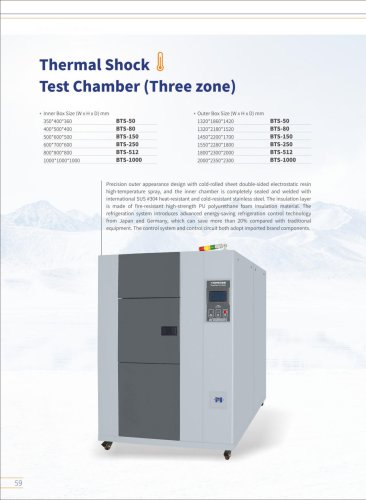

thermal shock test chamber

1 Pages

-

thermal shock test chamber

1 Pages

-

climate test chambers

1 Pages

-

Performance tester BE-8214

1 Pages

-

Dust test chamber BE-XR-12M³

1 Pages

-

Leak testing machine

1 Pages

-

Drop tester BE-8206-1500

1 Pages

-

Drop test chamber BE-8108

1 Pages

-

Flammability tester BE-8105

1 Pages

Archived catalogs

-

HAST test chamber BTH-1000D

1 Pages