Catalog excerpts

Large Current Short Circuit Test Resistive Cabinet Large Current Short Circuit Test Resistive Load bank Performance parameters BE-XL- 5000ADZ BE-XL-10000ADZ Max. Operating Current 5000A 10000A Resistance 1~100m< Adjustable 1~100m© Adjustable can choose to adjust the resistance value without pole or adjust in steps Eg 1mΩ ( Max.Operating Current 5000A ) 1mΩ ( Max.Operating Current 10000A ) 5mΩ ( Max.Operating Current 5000A ) 5mΩ ( Max.Operating Current 10000A ) 10mΩ ( Max.Operating Current 2000A ) 10mΩ ( Max.Operating Current 10000A ) 20mΩ ( Max.Operating Current 1000A ) 20mΩ ( Max.Operating Current 5000A ) 80mΩ ( Max.Operating Current 500A ) 80mΩ ( Max.Operating Current 1000A ) 100mΩ ( Max.Operating Current 500A ) 100mΩ ( Max.Operating Current 500A ) Heat dissipation 2 axial flow fans installed on the top with intelligent temperature control control system. Design Overview High-current short-circuit resistance cabinet line design shall be able to withstand the impact of high current colleagues to ensure the stability of the resistance value: contact copper plate and wire must be selected under the internal resistance value of all-copper material; resistance using graphite material resistance, resistance stability, resistance does not change with the temperature, resistance of very good linearity, you can adjust the resistance accuracy to 0.1mQ. Graphite resistor performance. 1. Thermal stability: for the use of the product rapid heat and cold conditions, special design to ensure the reliability of product quality. 2. Graphite has a high degree of electrical conductivity, can withstand more than 3000 °C high temperature, melting point 3800 °C, boiling point 4250 °C, with plasticity, chemical stability, insoluble in acid and alkali. 3. Corrosion resistance: uniform and fine matrix design delays the erosion degree of the product. 4. Impact resistance: the thermal shock strength that the product can withstand is extremely high, so any process treatment can be carried out with confidence. 5. Acid resistance: The addition of special materials significantly improves the quality of the product, which is excellent in terms of acid resistance index and greatly extends the service life of the product. 6. Control of metal contamination: The strict control of material composition ensures that the product does not contaminate metal when dissolving. 7. Quality stability: High-pressure formation of the production technology process and quality assurance system to more fully ensure the stability of quality. Design of graphite resistors 1. Connection: the use of series connection, connected through the copper plate 2. Graphite resistor: using round graphite resistor rod. Convenient for precision processing and assembly as well as easy adjustment of linear resistance value. 3. Structure: bracket support, multi-layer graphite assembly superimposed, side access to the wire. 4. The top of the structure is installed with high temperature resistant axial flow exhaust fan heat dissipation control system. When the graphite resistor is instantly overloaded to generate high temperature, the heat dissipation control system will automatically start the axial fan for air absorption and heat dissipation. And put out a red light alarm. Protect the graphite resistor and also remind the operator to pay attention to the safety of the experiment. 5. Heat dissipation partition network: steel wire sealing plate is installed on the left and right sides of the bracket to improve heat dissipation performance and high safety prote

Open the catalog to page 1All Guangdong Bell Experiment Equipment Co. catalogs and technical brochures

-

Battery Safety Test Chamber C

28 Pages

-

Environmental Test Chamber C

14 Pages

-

Flammability tester FLAMMABE

1 Pages

-

Crush test chamber BE-8111

1 Pages

-

vacuum drying oven BE-ZK-M

1 Pages

-

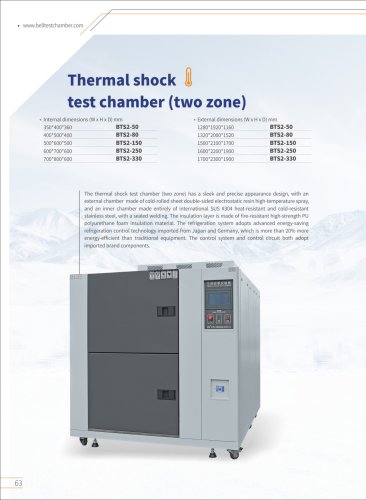

thermal shock test chamber

1 Pages

-

thermal shock test chamber

1 Pages

-

climate test chambers

1 Pages

-

Performance tester BE-8214

1 Pages

-

Dust test chamber BE-XR-12M³

1 Pages

-

Leak testing machine

1 Pages

-

Drop tester BE-8206-1500

1 Pages

-

Drop test chamber BE-8108

1 Pages

-

Flammability tester BE-8105

1 Pages

Archived catalogs

-

HAST test chamber BTH-1000D

1 Pages