Catalog excerpts

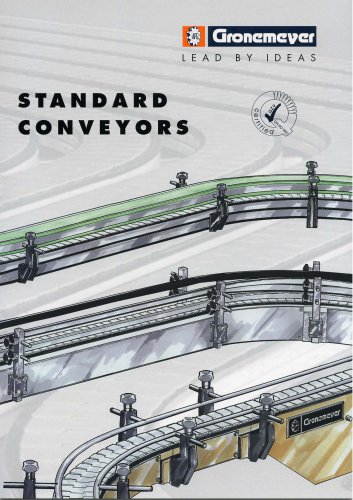

plus over several preceding straight running slat-band chain as well as the side flexing slat-band chains from America had been well establis- German market. construction have opened middle size products. Although Gronemeyer began business primarily with the sale of conveyor chains, they started complete conveyor systems special needs of individual continuous technical Standard Conveyor System which fulfills the requirements a reliable production flow.

Open the catalog to page 2

OUR STANDARD CONVEYOR SYSTEM What looks at first like a simple job of transporting goods from point A to point B can quickly develop into a complicated matter similar to threading the whole production line through well it all comes down to the reliable transport, many size, weight, material, These requirements are filled available construction Non-pressure separation • Production output (ex. high temperature, humidity, hygiene, combustible • Line design (ex. winding or spacious rooms) severity, accumulation frequency, multiple shift • Customer specified construction components, • Chain...

Open the catalog to page 3

Standard-System for slat band chain with hold down tabs (TAB) Another development extending from our original Gronemeyer modular complex transport lines. rectangular pipe on which the wear strip is fastened. The single pipes are screwed together using connecting rings to form a conveyor segment. Because of this angles and radius, as well as precision fitting transport lines down nearly to the exact millimetre. Also the down grade arches. A special wear resistant plastic is used for wear strip material. In cases of extreme environment conditions where consider using brass or stainless steel.

Open the catalog to page 4

Standard-System for slat band chain with bevelled guide shoes initially degreased and then given several coatings of enamel paint using the customer has free choice as our stainless steel version. conditions such as like in the meatpacking industry, the high corrosion resistant steel may be

Open the catalog to page 5

Buffer section with accumulation chain

Open the catalog to page 6

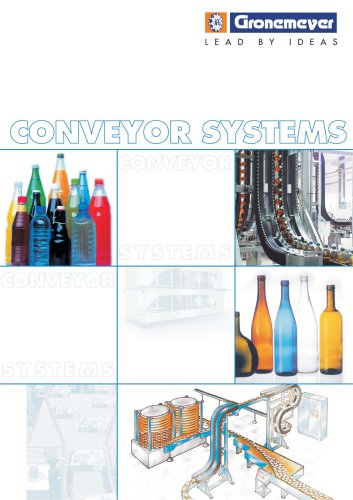

CONVEYOR TECHNIC: - feeding from 19 bundle packers to - 1700 meter conveyor section, made of Gronemeyer standard conveyors - 17 Gronemeyer vertical conveyors - 12 Gronemeyer distribution diverters - 3 single liners for specific products - over 50 different packing sizes - single line conveyor capacity speed up to 50 packs per minute - automatic buffer for stops due to storage adjustment of palette - supplied with traversable maintenance platforms OPERATING SYSTEM: - two separate PLCs Type Simatic S5 115U - exchangeability of all relevant operating parameters with a Master-PLC and Bus system...

Open the catalog to page 7

For long conveyor distances proven itself highly efficient through a minimum in weight side flange profiles the distance between supports meters. Inside and outside grooves allow a chipless installation. Guide rail peripheral components such as photo cells and pneumatic a very high degree. Not only can remounted in different ways, chipless mounted traverses and wear strips the conveyor can also be adjusted for different chain widths. Just the type of modular construction system The system is completed using side rail guiding which provides a high degree of rigidity with little weight.

Open the catalog to page 8

Simple chipless assembly of initiators and other auxiliary of this profile. Application only in dry work areas like the glass industry, but also in other industrial areas where sprays are used. Through the sporadic dampness. The system has proven itself machines with palettizer. Large spans and minimum maintenance requirements allow transport lines even in areas which are difficult to

Open the catalog to page 9

those with high sanitary Gronemeyer Hygienic- System. This system beverage, pharmaceutical, naturally all areas of food- The smooth sheet metal construction inhibits dirt return track of the chain is carried on plastic rollers allowing the conveyor chain to remain free of dripping remains open underneath and Collecting basins underwards funnelled to a central drain from where it can be recycled in an efficient type of Sectional view of the hygienic-system circulating lubrication system.

Open the catalog to page 10

Side flanges made of stainless steel-sheet (polished, sanded or glass bead shine) are giving a clean aspect. For aggressive high corrosion resistant steel. Conveying system with outward transfer buffer We happily await your call

Open the catalog to page 11

Gronemeyer Maschinenfabrik GmbH & Co. Rohrweg 31 D-37671 Hoxter - Germany Postfach 100253 D-37652 Hoxter - Germany

Open the catalog to page 12All Gronemeyer Maschinenfabrik GmbH & Co. catalogs and technical brochures

-

heliflex spiral buffer

4 Pages

-

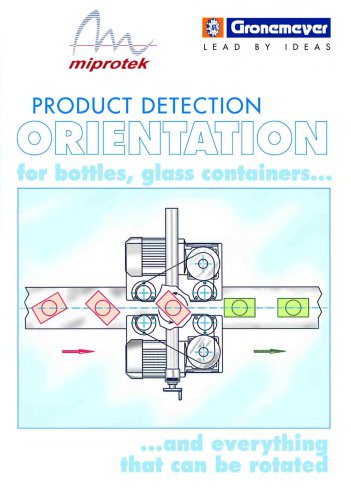

aligner station Brochure en

3 Pages

-

conveyor technology

20 Pages

-

FIFO spiral buffer

4 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

Vertical storage

1 Pages

-

synchronized distributor

4 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

Aluminium compact system

4 Pages

-

Gronemeyer Conveying Systems

20 Pages

-

SIDE GRIP CONVEYORS

2 Pages

-

SPIRAL FLOW SYSTEMS

2 Pages

-

CONVEYING SYSTEMS

13 Pages

-

Sweets Industry

4 Pages

-

Beverage industry

4 Pages

-

FIFO- Spiral Buffer

4 Pages

-

Conveyor Systems

20 Pages

-

Aluminium- Compact- System

6 Pages