Catalog excerpts

Our Company introduces itself: In the year 1918, August Paul Gronemeyer opened his company in Dusseldorf, which predominantly manufactured chains and elevators. It was apparent that he was a talented entrepreneur, with good business sense and he prided himself on his perfect workmanship. Production facilities were demolished during war time. The company was to be rebuilt in 1945 in Hoxter, Weser. ded the reins of the company over to Although Gunter continued to fol- low in his fathers footsteps he intro- duced modernization and expansion of production capacity, increasing struction and...

Open the catalog to page 2

Customer confidence, high quality commitment and delivery perfor- mance are of paramount importan- The introduction of a quality assu- rance system guarantees high quali- The production facilities with well proven drive components, enables achievement of necessary produc- tion level for special purpose machi- nes, particularly with respect to high availability of plant specific spare comprises of a dedicated team of experienced designers and engi- neers. Their knowledge and com- mitment make it possible for us to implementation of large complex

Open the catalog to page 3

Conceptual design, project engineering and implementation of complex conveyor solutions The conveying system is often overlooked within the big- ger scheme of project engineering of production facilities. It can be said that: Any system is only as powerful as its weakest link. With our presence as your partner, your conveyor system will not be that aforementioned weak link. Modern production machines need optimum linking. This is valid both for high capacity production lines as well as for the flexibility of product changeover. Integration of a fire protection terminal ■ development of...

Open the catalog to page 4

■ competent customer consultancy services by our project engineers CAD system layout ■ object specific cemand assessment tor conveyo' capacity calculation ■ suggestion and discussions with customer on possible solutions for line des.gn ■ automatic synchronization of interfaces with other suppliers ■ short delivery time of equipment from our large manufacturing facility B quality assurance at all slayes of oroe' processing ■ installation and commissioning by our experienced service staff ■ all year availability of specialized mechanics ■ a well organized stock and oui cutting edge production...

Open the catalog to page 5

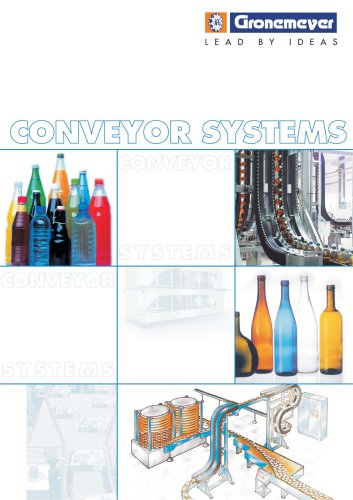

Conveyor system with slat-band and plate top chains Our conveyor systems are used for primary material flow of unit loads as well as for interlinking of production machines For these conveyor systems, straight and cur- plate top chains can be used. Ihese can be made from plastic, steel and stainless steel. Also we can offer modular plastic belts ferent types of conveyor systems are available. All systems are desi- gned in such a way that their indivi- dual components are assemoed together as a modular unit. If requi- conveyor can be easily obtained by rearranging some of the modular...

Open the catalog to page 6

Hygienic System This system is suitab e tcr wet opera- tion or especially for applications with high hygienic requirements. This is exclusively built with stainless steel and rustproof components. ne ooer construction prevents dirt deposits and facilitates easy For dry operations, we also offer the same construction in painted steel Whether it is with gears of fixed speed or with eleccronic/mecharical variable speed, all variants are avai- lable in shaft mounted execution or chain driven. All standard makes Aluminum Standard System

Open the catalog to page 7

Gronemeyer Side Grip Technology For space saving special applications, side grip technology trorr the house of Gronemeyer has proved to be successful for the last many years. It has been successfully used in many different types of industries for careful conveying in vertical direction. Because of the soft clamping process even sensitive oroducts can be con- veyed. D'ooping out or twisting the materia being transported is prevented with low contact pressure. Big products like KtGs, crates, cartons etc. can also be transported by appli- cation of a wider gripper chain. For small products...

Open the catalog to page 8

Gronemeyer Gripper Chain The key 10 iroublc-frec operation is the right selection of gripper chain. Based on the ongoing market demands of latest technology products, many different design variants of rubber profile and carriage plate have been developed over the years. Also for extremely demanding applications like ir the sugar and the detergent industry, the working life of these chains is very out- standing. Mary types of materia! for the gripper chain are suitable for use in wet appli cation or with applications with high ambient or product temperatures. Vertical Conveyor The vertical...

Open the catalog to page 9

Gronemeyer Side Grip Technology Bottle Turner Customized requirements or legal specifications often call for an internal cleaning of new containers of qlass or plastic, new PET bottles, cans etc. before tilling. Will: the Gronemeyer bottle turner, you have the facility of rinsing or blowing-out the new containers before filling. In this system, the products can be turned either upwards or downwards (depending on product and infeed height). This flexibility in construction also enables cleaning of the material to be conveyed together with up- or downward transport (e.g. from one floor into...

Open the catalog to page 10

Rinscr with downward movement Neck Sterilizing Due to procedural reasons within the beverage production, often moiste- ning of the bottle neck with the pro duct for few seconds becomes necessary. Both in cold and hot filling, our neck sterilizer has proved to be successful. The design adapts itself to the system specific parameters such as conveying capa city and moistening time. Due to the vertical moistening routes, the machine can also be integrated later on in any filling line even within limited space. Neck sterilizer with revolving disk to reduce wear of chain and wear strips Roadway...

Open the catalog to page 11

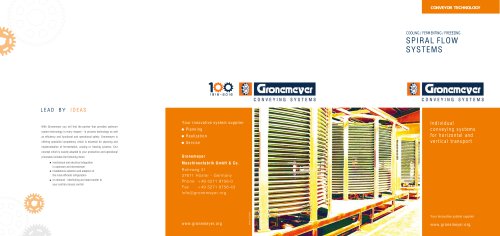

Gronemeyer Spiral Flow Systems With the application of our Gronemeyer spiral flow systems, it is possible to handle o'cducts in single or multiple tracks in a very limited space during pro- cess operations, it cooling, fermenting or freezing s required in continuous material flow, the products pass through an air conditioned chamber. The complete system consists of spiral system and cold/chilling cell, which is designed as per specific application and is handed over to the customer on As per process requ rements, product shape and conditions, Gronemeyer offers various specifically designed...

Open the catalog to page 12All Gronemeyer Maschinenfabrik GmbH & Co. catalogs and technical brochures

-

heliflex spiral buffer

4 Pages

-

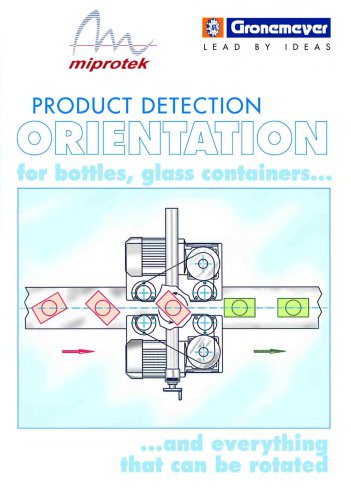

aligner station Brochure en

3 Pages

-

conveyor technology

20 Pages

-

FIFO spiral buffer

4 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

Vertical storage

1 Pages

-

synchronized distributor

4 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

conveyor technology

20 Pages

-

Aluminium compact system

4 Pages

-

Gronemeyer Conveying Systems

20 Pages

-

SIDE GRIP CONVEYORS

2 Pages

-

SPIRAL FLOW SYSTEMS

2 Pages

-

CONVEYING SYSTEMS

13 Pages

-

Sweets Industry

4 Pages

-

Beverage industry

4 Pages

-

FIFO- Spiral Buffer

4 Pages

-

Aluminium- Compact- System

6 Pages

-

Standars conveyor

12 Pages