Catalog excerpts

GROB-Werke Technological competence through generations

Open the catalog to page 1

In the beginning there is an idea. Contents GROB Mindelheim plant System Business Universal machining center Planning Design and Development Production Assembly & Installation Service Technical Training GROB Departments

Open the catalog to page 2

GROB Mindelheim plant: The Beating Heart of GROB-WERKE Is Nestled in Bavaria. National roots and regional responsibility Established in 1968 as a supplier plant to GROB’s headquarters in Munich, what began on a mere 1500 square meters of ground in Mindelheim, Bavaria has grown five decades later into one of the largest employers and training facilities in the region. A workforce of over 2900 people is currently employed at the Mindelheim facility, which now fills ten halls and spans over 200,000 square meters. The success story goes on, with yet another expansion of the Mindelheim facility...

Open the catalog to page 3

System Business: Boundless Permutations. Competence In State-ofthe-Art Technology Around the World There are two things we consider to be of utmost importance at GROB: our customers and their products. In order to ensure optimum implementation of our production equipment, we foster a close relationship with our customers, acting as a point of contact on all strategic matters. Decades of experience, as well as high quality and dependability in both design and delivery serve to ensure that GROB customers enjoy optimum support in all aspects of the system business. The fact that GROB has...

Open the catalog to page 4

Universal machining center business: An innovation makes its mark. The “G” Success Story Goes On and On Drawing upon their wealth of development experience, GROB engineers have developed a five-axis universal machining center for all cutting users. The proven G-module technology, built upon experience and expertise acquired from the automotive manufacturing industry, has been transferred to the technology and design of the G350, the G550 and the G750. Further innovative developments, such as the hydraulics-free machine tool and the milling and turning center, have led to fast successes in...

Open the catalog to page 5

Planning: The Nucleus For Successful Ideas and Products. The Link Between Requirements and Process Design In Planning, ideas are conceived as the cornerstones for success in customer projects. Here at GROB, Planning is not interpreted as a catalytic convertor for customer requirements with existing technologies; for years we have seen it as a source of innovation and the link between Design and Development. It brings together decades of experience, high levels of technical expertise and optimum competence right along the process chain, from cutting to assembly and on to engineering. Our...

Open the catalog to page 6

Design and Development: The Heart of the Company. Ahead of Its Time – With Its Sights Set On Reality Here at GROB, Design and Development are the significant starting points for the competitiveness and success of the company. In order to rise to the challenge, our technicians and engineers have to fulfill a variety of requirements, some of which can be rather contradictory. Exhibiting a wealth of creativity and a large dose of lateral thinking, our technicians and engineers veer away from paths that necessity steers them down in order to develop new, innovative concepts. This is always done...

Open the catalog to page 7

Production: World-Class - Production of the Highest Standard. Taking Shared Responsibility At GROB-WERKE, we’ve achieved our ambitious target of world-class production through different optimization processes. Segmenting production workflow, reducing internal cycle times and the refinement of process strategies have all factored into the optimization process. The highly vertical process along the entire production chain, including a wide variety of machining technologies and employee expertise, creates the perfect basis to meet customer needs. This vertical production process allows for the...

Open the catalog to page 8

Assembly & Installation: Experience and Dexterity. Core Competence in All Aspects of the Machining Process From sub-assembly to installation, then proceeding right through start-up and commissioning, GROB employees demonstrate their core competences in all aspects of customer relations. GROB Logistics Management ensures that workflows run with optimum results from beginning to end. A specially developed system of shop-floor management integrates the employees into our functional module. State-ofthe-art IT support makes the availability of material transparent in real time, creating an...

Open the catalog to page 9

Service: Worldwide Ambassadors For GROB-WERKE. GROB Service Connects: Anytime, Any Place Our service begins with the planning and coordination of machine installation and supports the customer through the start of production. It also includes the coordination of training services, advice on the most optimal system utilization, overhauling installations and support for machine faults during the production process. This applies to all deliveries from the four production facilities in Bluffton (USA), São Paulo (Brazil), Dalian (PR China) and Mindelheim (Germany) to all corners of the globe....

Open the catalog to page 10

Technical Training: Foundations For a Successful Future. In the long tradition of our company The over 1400 young apprentices at our Mindelheim facility personify our ongoing commitment to training the next crop of skilled workers. And this goes beyond Germany. GROB has been writing its own success story in Brazil, and the US in particular, with its dual-vocational training system, setting an example for the whole sector to follow. There are ideal training opportunities available in our hightech training department, as well as in carefully selected training centers within our different...

Open the catalog to page 11

GROB Departments: Reliable Basis For the Success of the Company. Our Behind-the-Scenes Networkers GROB has explored particular avenues in process and cost optimization. The company performs pioneering work with its “GROB Production System” (G-PS). G-PS describes methods and principles that make an important contribution towards the development of products or processes throughout the company. Not least of all, the proportion of added value within the company has been decisively improved by G-PS. As with sports, team skills are also highly important to companies. Everyone in the company is...

Open the catalog to page 12All GROB-WERKE catalogs and technical brochures

-

GROB Group brochure

40 Pages

-

GROB International 02/2017

11 Pages

-

GROB International 01/2018

16 Pages

-

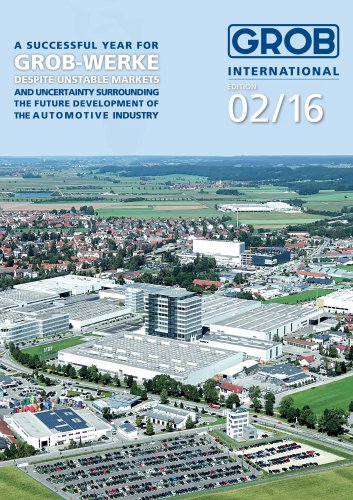

INTERNATIONAL EDITION 02/16

15 Pages

-

GROB International 02/15

9 Pages

-

GROB International 01/15

11 Pages

-

INTERNATIONAL Issue 02/14

11 Pages

-

INTERNATIONAL Edition 01/14

20 Pages

-

GROB International 01/10

9 Pages

-

GROB International 02/10

9 Pages

-

GROB International 01/11

9 Pages

-

GROB International 02/11

11 Pages

-

GROB International 01/13

11 Pages

-

GROB International 02/13

20 Pages

-

GROB International 01/12

11 Pages

-

GROB International 02/12

11 Pages