Catalog excerpts

Single-Width Centrifugal Fan Performance Supplement • Engineering Information • Air Performance • Sound Performance • Dimensional Data

Open the catalog to page 1

Table of Contents Engineering Data Air and Sound Performance Data Dimensional Data Sizes Sizes Sizes Sizes All Greenheck products are supported by the industry’s best product literature, electronic media, and Computer Aided Product Selection program, CAPS. Online, you can also find electronic copies of our product literature as well as storage, installation and maintenance information in our Installation and Operation Manuals. And, of course, you can always count on the personal service and expertise of our national and international representative organization. To locate your nearest...

Open the catalog to page 2

Engineering Data Motor Selection Greenheck centrifugal fans can be supplied with any motor that is commercially available, and appropriate for the fan size and performance required. The tables show motor frame sizes corresponding to those motors readily available. See the maximum motor frame size charts below if motor is for arrangement 9 or 10 fans. Notes: 1. Fractional horsepower motor frame sizes shown may change due to variations in voltage, special features and manufacturer. 2. Motors shown are ball bearing, continuous duty. Two speed motors are two winding, 1/3 reduction in RPM. 3....

Open the catalog to page 3

Engineering Data Motor Starting Torque When selecting a motor for a centrifugal fan, the motor must be capable of driving the fan at operating speed and also capable of accelerating the fan wheel, shaft and drive to the operating speed. Moments of inertia are shown for steel wheels. Aluminum wheels are one-third of the value shown. The fan performance tables and curves in this catalog show the brake horsepower required to operate the fan once it is brought to operating speed. For applications requiring a large air volume at a low static pressure, the BHP required at the fan’s operating RPM...

Open the catalog to page 4

Engineering Data Inlet Vane Performance As inlet vanes are closed, they impart a spin to the airflow in the direction of wheel rotation and reduce airflow, static pressure and brake horsepower as shown in the graphs below. The graphs show how CFM, static pressure and brake horsepower are affected as inlet vanes are modulated from 100% open to 0% open in a typical variable air volume system. Graph 3 provides RPM and BHP correction factors for fans equipped with inlet vanes. 100 80 % Peak Brake Horsepower % Peak Static Pressure % Wide Open Volume % Wide Open Volume RPM & BHP Corrections To...

Open the catalog to page 5

Engineering Data Effect of Air Density – Temperature and Elevation Ratings in the fan performance tables and curves of this catalog are based on standard air (clean, dry air with a density of 0.075 pounds per cubic foot, barometric pressure at sea level of 406.75 inches wg, temperature of 70°F). Selecting a fan to operate at conditions other than standard air requires an adjustment to both static pressure and brake horsepower. One cubic foot of air has a constant volume regardless of temperature or elevation. However, air density changes with non-standard temperature or elevation....

Open the catalog to page 6

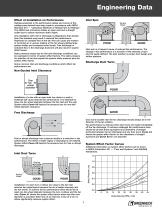

GOOD GOOD GOOD Inlet spin is a frequent cause of reduced fan performance. The change in fan performance is a function of the intensity of spin GOOD POOR and not easily defined. The best solution is proper duct GOOD design and POOR n tio airflow patterns. a Ro t Length of effect factors. The static pressure be expressed in terms of systemStraight Duct for selection oftion fans equals the system static pressure plus the the GOOD a system teffect factor. GOOD ion Turning Turning Vanes Vanes POOR POOR POOR Length POOR of Straight Duct Static pressure losses due to inlet and discharge conditions...

Open the catalog to page 7

Sound Performance Testing AMCA Licensed Ratings Sound tests of Model BISW and AFSW were conducted in Greenheck Fan Corporation’s AMCA Accredited sound laboratory in accordance with AMCA Standard 300. Inlet and outlet sound ratings comply with AMCA Publication 311, qualifying these models to bear the AMCA Seal for Sound and Air Performance. The sound power levels published here can be compared directly with those of other similarly rated fans, or used as a baseline to determine sound levels in occupied spaces. The sound data in this brochure is the result of extensive testing, which included...

Open the catalog to page 8

Sound Performance Testing Outlet Sound – Duct End Corrections This correction accounts for sound that is reflected back into the duct where there is an abrupt termination of the duct. AMCA Standard 300 requires that outlet sound power for fans with ducted outlets include Duct End Corrections. These corrections account for any sound power that may be present in the duct but is not measured in the reverberant room, because it is reflected back into the duct at the discharge. Duct end corrections are included in all outlet sound power ratings. Tolerance and Application The certification...

Open the catalog to page 9

Sample Fan Selection Sound and Air performance are identical for Greenheck Series 21 and 41 centrifugal fans. The following example explains the model number code for both series of centrifugal fans. The purpose of these two pages is to demonstrate the manual centrifugal fan selection process. These pages also contain helpful tips to check your fan selection, as well as a step-by-step set of instructions on how to use this manual to properly select a centrifugal fan. An important point to remember when manually selecting a centrifugal fan is that more than one fan is available to meet the...

Open the catalog to page 10

Fan Selection Procedure STEP 1 Enter the performance table with the desired CFM and Ps. Obtain the fan RPM, BHP and Class. STEP 2 Enter the Fan Curve with the desired CFM and Ps. Obtain the fan operating point, % WOV, Motor HP and verify fan class by curve shading. EXAMPLE For this example, we will use 19,100 CFM at 4.0 Ps. This gives us a fan RPM of 995, requiring 17.2 BHP, with Class I construction. EXAMPLE For this example, the fan operating point is at 60% WOV using a 20 HP motor. NOTE: If your specific fan selection requires inlet vanes or if the fan operating point is not at standard...

Open the catalog to page 11All Greenheck catalogs and technical brochures

-

building value in air WORLDWIDE

56 Pages

-

Model TAUD TAUB-CA

24 Pages

-

Model TAUB-L/H

16 Pages

-

Model AX

8 Pages

-

Models QEI QEID

52 Pages

-

Models TCB TCBRU TCBRS

32 Pages

-

Inline Fans (Models SQ and BSQ)

48 Pages

-

Greenheck Coils Brochure

8 Pages

-

Bypass Air Plenum

2 Pages

-

Belt Drive Duct Fans (Model BDF)

12 Pages

-

Models IDHC and IDHB

8 Pages

-

Centrifugal Roof Exhaust Fans

52 Pages

-

Industrial Process Fans

12 Pages

-

AMCA & Greenheck

2 Pages

-

Air Measuring Products

8 Pages