Catalog excerpts

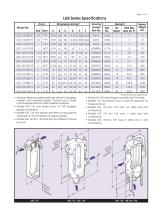

Graver Technologies CONSLER LGS SERIES COMPRESSED GAS SEPARATORS Features • ASME Code designed and constructed • High flow rate capabilities • Low pressure drop and long element life • High temperature capability • Economical, replaceable cartridges • Modified and custom designs available Applications • Effective separation of oil, water and other liquid aerosols from compressed air and gas lines. • High efficiency removal of: - Dispersed liquids, 4pm & up, 99% - Solid particles, 1pm & up, 99% • Use as a prefilter to an air dryer, increasing system efficiency and equipment service life. • Gas pipeline applications, to protect equipment from liquid and solid contaminants. • Ideal for satisfying original equip. mfr. specifications. Element Design & Construction The LGS Series filters offer a high efficiency coalescing style element. Each model employs one or more of these replaceable element cartridges which provide positive gasket sealing to prevent by-pass of unfiltered gases. Long filter life, low pressure drop, and efficient filtration and coalescing action are assured. This coalescing action is simply a "gathering" of minute liquid particles or smaller droplets to form larger droplets. The small droplets that enter the inside of the element are intercepted or impinged by the filter media and extracted from the gas stream. The larger droplets once formed, drain off the outside of the element and fall by gravity to the sump area in the filter housing where a drain connection is provided for removing the coalesced liquid. The high efficiency element prevents re-entrainment of liquid downstream. The coalescing/ draining action continues at the same rate that new liquid enters the element, allowing long service life before element replacement is required. The LGS Series filters are designed to handle liquid concentrations up to 1000 ppm and are capable of providing downstream air having less than 5 ppm of liquid. Dew point remains unaffected by the coalescing action. Element Materials Standard elements are composed of extremely fine borosilicate glass fibers with a resin binder, in a cylindrical, depth-type design. LGS Series elements may be used in service temperatures up to 200° F, and an optional element style permits high temperatures up to 400° F in continuous service and 450° F intermittently. Standard elements are furnished with plated steel center core and end caps. Stainless steel and other materials are also available. Housing Design and Construction Housings are designed and constructed in accordance with ASME Code Sec. Vlll Division I requirements for unfired pressure vessels (6 1/4" diameter and above). Models LGS 115 and above are available with "U" stamp registration and certification. All models can be quickly serviced without breaking pipe connections. Models LGS 120 and up are furnished with 1/4" NPT gauge connections on the inlet/outlet nozzles. Standard models LGS 130 and above are furnished with leg supports. Model LGS 160 has a hinged closure device, and Models LGS 170 and above are equipped with a davit lifting device for cover removal. Standard filter housings may also be modified or customized to meet unique or special application needs. Typical design modifications include: special leg lengths, end connection types, inlet/outlet orientations, modified closure styles, and special controls and accessories. Special gasket and element materials will allow the filter vessel to be applied in service conditions up to its maximum design of 180 psig at 466° F. Filter Materials and Ratings • Housings - Carbon Steel LGS 110:150 psig at 100° F max. LGS 115 & larger, threaded conns:180 psig at 650° F max. LGS 115 & larger, flange conns:180 psig at 466° F max. • Closure Gasket - NEOPRENE*; 300° F max. • Standard Elements - Fiberglass media; 4 micron retention at 99% for dispersed liquids, 1 micron at 99% for solids; 250° F max; not cleanable. Optional elements up to 400° *DuPont registered

Open the catalog to page 1

• Standard filters are supplied with high efficiency fiberglass medium and neoprene gasket. Contact your Consler bnand representative for other available materials. • Models LGS 120 and above have 1/4" NPT plugged gauge connections. • Models LGS 130 and above have three (3) leg supports with length of 18" from bottom of vessel to grade. • Models LGS 140 thru 150 have two (2) handles for closure removal *All dimensions are approximate. • Model LGS 160 has a hinged cover with one (1) handle. • Models 170 and above have a davit lift assembly for closure removal. • Models LGS 115 thru 135 have...

Open the catalog to page 2

LGS Flow Rate Capatibility Charts1Capacity (SCFM) vs. Differential Pressure (psi) At 60° F-Gas Specific Gravity 1.0 (Air)2 LGS Model 1. Values are based on actual test results or empirical calculations. Optional Automatic Drain Valve For automatic drainage of the coalesced liquid without system shutdown. Drain valves are cast iron and float operated for wide variations in flow with a maximum capacity of 2 gpm. A shut off valve is also supplied to allow periodic service while the Filter/Separator remains in operation. Recommended for compressed air and inert gas applications only. Drain...

Open the catalog to page 3

(Reference: Mechanical Engineers' Handbook by L.S. Marks, copyright May 1954; McGraw-Hill Book Co., Inc.) For correction factors for gases other than those listed above, contact Graver. Graver Technologies also makes: • Air Intake Filters • Air Intake Filter/Silencers • Air/Gas Pressure Filters • Vacuum Filters • Liquid Filters/Strainers • Smoke/Oil Mist Eliminators • Filter Separators • Special and Custom-Designed Filters and Filter Elements • Lube Oil Filters and Filter Elements Graver Technologies has representatives in major cities of the United States, Mexico and Canada....

Open the catalog to page 4All Graver Technologies catalogs and technical brochures

-

GLP

2 Pages

-

Citadel

2 Pages

-

Stratum™ C Series

8 Pages

-

Healthcare Brochure

4 Pages

-

Beverage Brochure

6 Pages

-

Products

2 Pages

-

Compressed Gas Filters

8 Pages

-

Exhaust Filters

4 Pages

-

Air Intake Panel Filter

6 Pages

-

Air Intake Filter

4 Pages

-

Liquid Filter Housings

7 Pages

-

Low Pressure Gas Filters

4 Pages

-

Oil Mist Coalescers

2 Pages

-

Nitric Acid Filters

4 Pages

-

Ecosorb ® S-406

1 Pages

-

Ecosorb ® C-945

1 Pages

-

Ecosorb ® C-941

1 Pages

-

Ecosorb ® C-908

1 Pages

-

GTX 323-E Brochure

8 Pages

-

Backwashing Membranes

1 Pages

-

Stratum Series Brochure

8 Pages

-

Scepter Product Brochure

8 Pages

-

Vacuum Filters

4 Pages

-

Air - Gas Filter/Separators

6 Pages

-

Housing & Elements

2 Pages

-

Air & Gas Filters

2 Pages

-

W-762 MSDS

4 Pages

-

S-406 MSDS

4 Pages

-

C-906 MSDS

4 Pages

-

W-701

1 Pages

-

S-405

1 Pages

-

C-902

1 Pages

-

Metsorb® HMRG

2 Pages

-

Metsorb® HMRP

2 Pages