Catalog excerpts

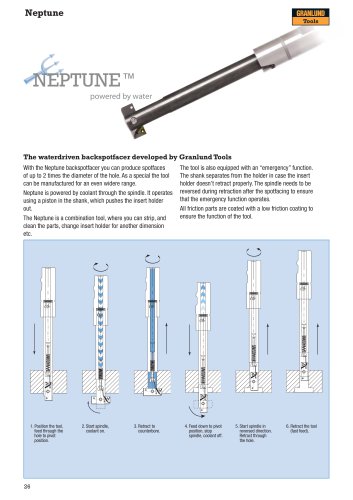

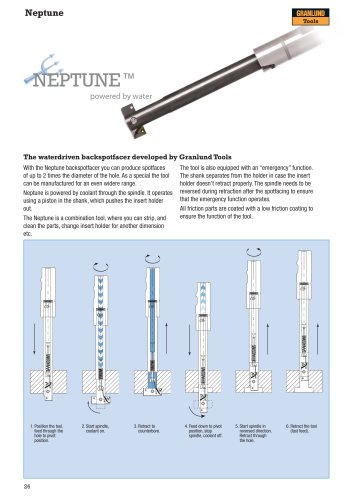

Neptune Tools The waterdriven backspotfacer developed by Granlund Tools With the Neptune backspotfacer you can produce spotfaces of up to 2 times the diameter of the hole. As a special the tool can be manufactured for an even widere range. Neptune is powered by coolant through the spindle. It operates using a piston in the shank, which pushes the insert holder out. The Neptune is a combination tool, where you can strip, and clean the parts, change insert holder for another dimension etc. 1. Position the tool, feed through the hole to pivot position. 2. Start spindle, coolant on. The tool is also equipped with an “emergency” function. The shank separates from the holder in case the insert holder doesn’t retract properly. The spindle needs to be reversed during retraction after the spotfacing to ensure that the emergency function operates. All friction parts are coated with a low friction coating to ensure the function of the tool. 4. Feed down to pivot position, stop spindle, coolant off. 5. Start spindle in reversed direction. Retract through the hole. 6. Retract the tool (fast feed).

Open the catalog to page 1

Cutting data for backspotfacer type NE Cast iron Cast aluminium • Coolant through the spindle or by means of a coolant adapter is required to operate the tool. For reliable operation the pressure should be >3 bars and the flow >30 l/min. Before using the tool, make sure that the insert holder pivots freely, lubricate and clean

Open the catalog to page 2All Granlund Tools catalogs and technical brochures

-

Backspotfacing system

2 Pages

-

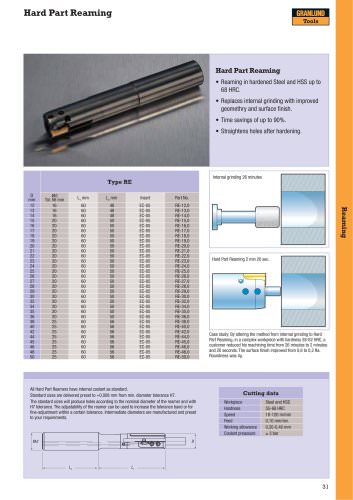

Hard Part Reaming

3 Pages

-

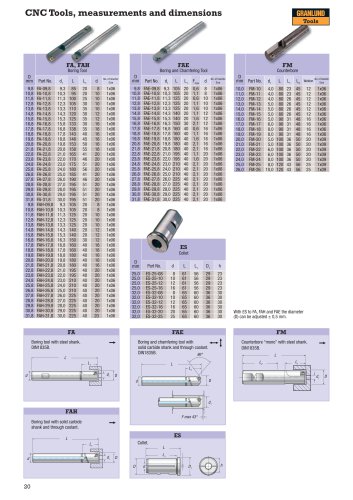

CNN tools

3 Pages

-

Counterboring System Size 01

2 Pages

-

carbide reamer

2 Pages

-

Countersinks

2 Pages

-

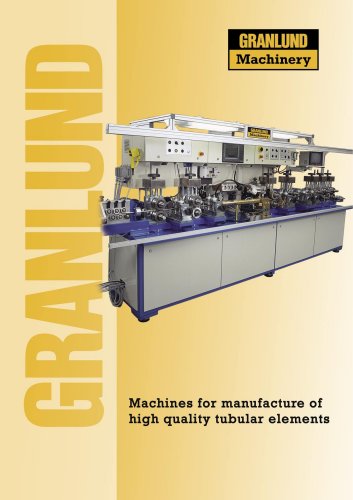

granlund Machinery

24 Pages

-

Main Catalogue EN

42 Pages

-

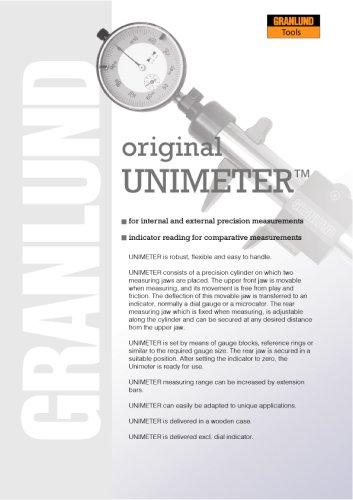

Original UNIMETER

5 Pages

Archived catalogs

-

CNC Tools

3 Pages

-

Counterboring System

2 Pages