Website:

Granlund Tools

Website:

Granlund Tools

Catalog excerpts

Carbide reamers, re-sizeable and xed Tools Solid reamer, left hand spiral 8-10°, extreme differential pitch. Solid carbide tip 6-11 mm, brazed utes Ø 12-40 mm. Grade ISO K10. DIN8094 Form B. Solid reamer, left hand spiral 8-10°, extreme differential pitch. Solid carbide tip 6-11 mm, brazed utes Ø 12-40 mm. Grade ISO K10. Solid reamer, straight utes, extreme differential pitch. Grade ISO K10. DIN 8051 Form A. Solid reamer, straight utes, extreme differential pitch. Grade ISO K10. Common features: Solid reamer, straight utes, extreme differential. Cermet: high cutting speed and wear resistance in steel and cast iron applications. The optimum solution when the cutting conditions are stable. • Reamers are stocked in tolerance H7 and also semi-nished for quick conversion to customers’ requirements. 45° • Differential pitched utes, for round holes and elimination of vibration. • Lapped utes for a better surface nish.

Open the catalog to page 1

Fully oating toolholders for reamers Type Shank Internal tting Floating holders for reamers Re-sizeable reamer, straight utes, differential pitch, for through holes. Grade ISO K10. 58° The expanding reamer can be resized to offset wear by driving the expansion plug further 60° into the reamer. Resizing can normally be done 2-3 times with regrinding. Driving the 62° plug 1 mm further into the reamer will increase the diameter by 0,033 mm. Note: Type 511 reamer cannot be resized to smaller diameters. L These have been designed to compensate parallel and angular mis-alignement of the reamer...

Open the catalog to page 2All Granlund Tools catalogs and technical brochures

-

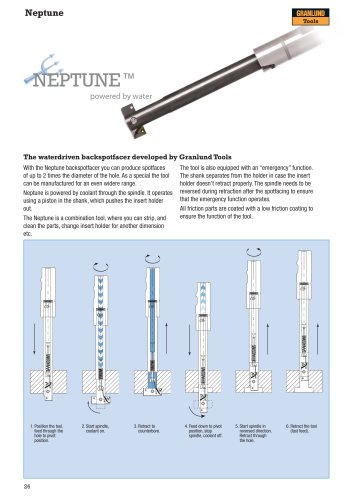

Backspotfacing system

2 Pages

-

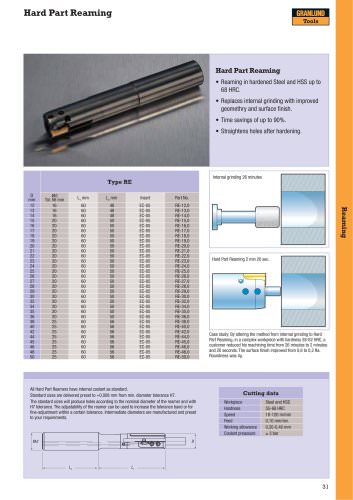

Hard Part Reaming

3 Pages

-

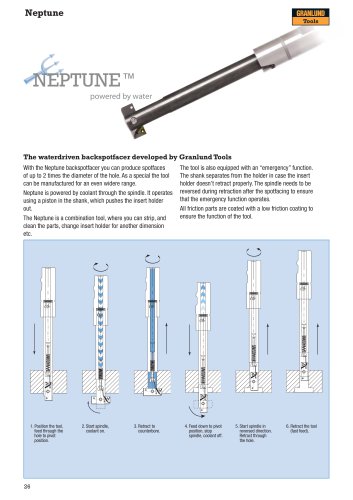

Neptune

2 Pages

-

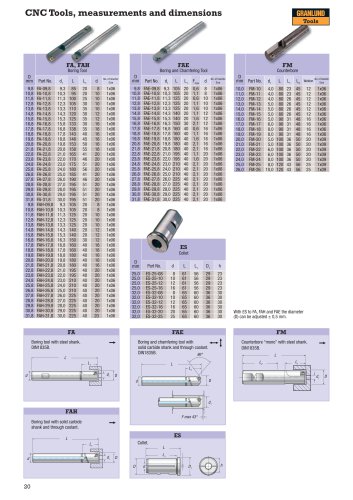

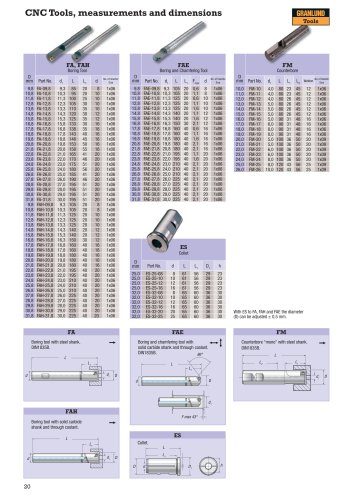

CNN tools

3 Pages

-

Counterboring System Size 01

2 Pages

-

Countersinks

2 Pages

-

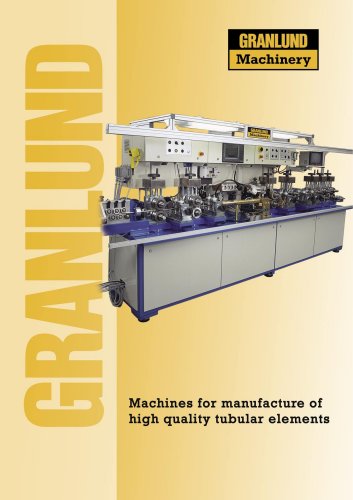

granlund Machinery

24 Pages

-

Main Catalogue EN

42 Pages

-

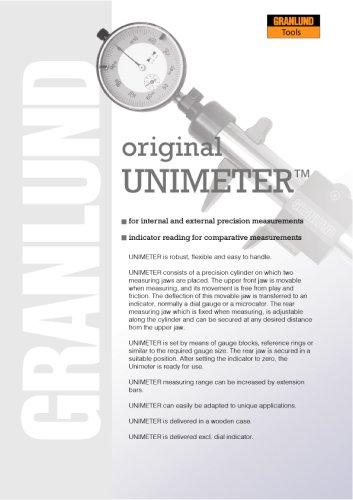

Original UNIMETER

5 Pages

Archived catalogs

-

CNC Tools

3 Pages

-

Counterboring System

2 Pages