Catalog excerpts

Goulds HT 3196 Goulds Pumps Goulds 3196 Process Pump with Patented Intelligent Monitoring

Open the catalog to page 1

2 Goulds 3196 Proven Performance... Over One Million Process Pump Installations Worldwide When the Goulds 3196 ANSI Standard Dimension Process Pump was first introduced in 1961, it immediately became the standard for the industry. Today, the number of installations attest to its remarkable performance. Users in chemical, petrochemical, pulp & paper, primary metals, food & beverage and general industries know they can make no better choice than the best — Goulds Model 3196.

Open the catalog to page 2

Maintenance Cost $32,000 Purchase Cost $8,000 Installation Cost $16,000 Operating & Energy Cost $44,000 Goulds 3196 3 In order to select a chemical process pump wisely, consideration must be given to design features that provide long-term reliable performance. The pump must be designed for optimum shaft seal and bearing life to prevent the failure of these two primary causes of pump downtime. IMPELLER Must be designed for long-term, maintainable performance and minimum hydraulic loads for maximum reliability. SEAL CHAMBER Must be designed for favorable seal environment — proper heat...

Open the catalog to page 3

Goulds 3196 4 Open Impeller Enclosed-type Impeller Fully Open Impeller Two Times More Wear Area Longer Life, Reduced Repair Costs The most critical wear areas of a pump are the casing and stuffing box/seal chamber clearances. At a given wear rate, the larger wear area means longer life. Remarkably, Goulds had performance in mind when the Model 3196 standard dimension process pump was developed in 1959. Of timely significance was the decision to feature a fully open impeller rather than an enclosed type. There are three excellent reasons why: Greater wear area for longer life Renewable...

Open the catalog to page 4

Goulds 3196 5 Maintained High-Performance Long Pump Life It is common knowledge that as a pump wears, the performance decreases. Goulds open impeller can be adjusted, simply and quickly, to compensate for wear and renew performance. The enclosed type impeller cannot be adjusted. Performance renewal requires new or repaired casing and impeller. 38% INCREASED NPSH 14 4 8 12 0 0 40 80 100 160 NPSH(FT) CAPACITY (GPM) 0 40 80 100 160 CAPACITY (GPM) 0 40 80 100 160 CAPACITY (GPM) 2% INCREASED POWER 40 30 20 POWER(BHP) 3% REDUCTION TDH 9% REDUCTION FLOW 470 450 430 HEAD(FT) Typical reduction in...

Open the catalog to page 5

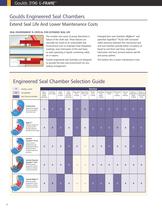

Goulds 3196 6 Goulds Engineered Seal Chambers Extend Seal Life And Lower Maintenance Costs The number one cause of pump downtime is failure of the shaft seal. These failures are normally the result of an unfavorable seal environment such as improper heat dissipation (cooling), poor lubrication of the seal faces, or seals operating in liquids containing solids, air or vapors. Goulds engineered seal chambers are designed to provide the best seal environment for any sealing arrangement. Enlarged bore seal chambers (BigBoreTM and patented TaperBoreTM PLUS) with increased radial clearance...

Open the catalog to page 6

Goulds 3196 7 Goulds Dynamic Seal Eliminate Sealing Problems, Reduce Maintenance Costs On tough pumping services, especially corrosives and slurries, mechanical seals require outside flush and constant, costly attention. Even then, seal failures are common, resulting in downtime. Goulds offers a solution: The Dynamic Seal which, simply by fitting a repeller between the stuffing box cover and impeller, eliminates the need for a mechanical seal. BENEFITS OF DYNAMIC SEAL: • Eliminate use of seal water • Eliminate pumpage contamination and product dilution • Reduce utility cost • Eliminate...

Open the catalog to page 7

2 1 5 2 4 3 1 The heart of the , the condition monitor unit continuously measures vibration and temperature at the thrust bearing and automatically indicates when pre-set levels of vibration and temperature have been exceeded, so that changes to the process or machine can be made before failure occurs. A visual indication of pump health makes walk-around inspections more efficient and accurate. The result is a more robust process to monitor and maintain all your ANSI pumps so that your plant profitability is maximized. Patented Condition Monitor Optimized Oil Sump Design Internal sump...

Open the catalog to page 8

Shaft and Bearings Engineered for Maximum Reliability The rugged shaft and bearing combination maintains shaft deflection of less than 0.002 inches at all operating points. The result is longer seal and bearing life. Premium severe-duty thrust bearings increase bearing fatigue life by 2-5X. • High purity steels have fewer inclusions than standard steel — better grain structure and wear resistance. • Heat treatment of bearing elements increases hardness for increased fatigue life. Forty-degree contact angle on the thrust bearing for higher thrust load capability. • 35% higher dynamic load...

Open the catalog to page 9

CONDITION MONITOR (Patent Pending) Constantly measures vibration and temperature at the thrust bearing. Colored LED’s indicate general pump health. Provides early warning of improper operation before catastrophic failure occurs. INPRO VBXX-D HYBRID LABYRINTH SEALS Prevents premature bearing failure caused by lubricant contamination or loss of oil. Stainless steel rotors for optimal performance in corrosive environments. CONTINUOUS PERFORMANCE Original flow, pressure and efficiency are maintained by simple external adjustment resulting in long-term energy and repair parts savings. PREMIUM...

Open the catalog to page 10

Goulds 3196 12 Baseplate Mounting Systems Goulds offers a complete range of pump mounting systems to meet plant requirements; make installation and maintenance easier. STANDARD OPTIONAL *Engineered option—requires special baseplate PLANT REQUIREMENTS Corrosion Resistance (mild/moderate) Corrosion Resistance (severe) Machined Pump & Motor Parts Circular Grout Holes (4 in. min.) Vent Holes (1 in. min.) Vent Holes (1/2 in. min.) Non-Overhang Full Drain Rim Built-in Drain Pan (under pump) Drain Pan Under Pump Baseplate Leveling Screws Motor Alignment Adjusters Lifting Feature Continuous Welding...

Open the catalog to page 11All Goulds Pumps catalogs and technical brochures

-

IC i-FRAME series

11 Pages

-

3420 series

11 Pages

-

3316 series

12 Pages

-

JC series

12 Pages

-

3175 series

16 Pages

-

3196 i-FRAME series

24 Pages

-

AF series

8 Pages

-

3180

20 Pages

-

3700

12 Pages

-

Goulds 7200SB

12 Pages

-

Vertical Turbine Pumps

20 Pages

-

Goulds 3400

11 Pages

-

Goulds AF

8 Pages

-

IC i-FRAME

24 Pages

-

Goulds API 3600 i-FRAME®

12 Pages

-

Goulds ICP

8 Pages

-

Goulds ICO i-FRAME® Series

16 Pages

-

Goulds API 3620 i-FRAME®

16 Pages

-

Goulds 3175

16 Pages

-

Goulds API 3171

8 Pages

-

Goulds 3171 / CV 3171

16 Pages

-

Goulds 3355

7 Pages

-

Goulds 3335

4 Pages

-

Goulds 3316

12 Pages

-

Goulds 3298

20 Pages

-

Goulds 3180

20 Pages

-

Goulds JC Slurry Pump

10 Pages

-

Goulds JCU

8 Pages

-

Goulds HS / HSD

4 Pages

-

Goulds ICB Close-Coupled

19 Pages

-

Goulds 3196 i-FRAME Process Pump

19 Pages

-

7200CB Barrel Multistage Pumps

12 Pages

-

Goulds 3640

8 Pages

-

Pump Selection Guide

16 Pages

-

Goulds Model JC Slurry Pump

10 Pages

-

Vertical Cantilever Pump VHS

9 Pages

-

SealPlus Mechanical Seals

4 Pages

-

ICM

8 Pages

-

Mining & Mineral Processing

12 Pages

-

Products for Pulp and Paper

4 Pages

-

Pumps for Power Generation

8 Pages

-

Wet Pit Column Pumps

4 Pages

-

Single Suction Dry Pit Pumps

2 Pages

-

Model HS and HSD

4 Pages

-

LF 3196 i-FRAME

11 Pages

-

CV 3196 i-FRAME

11 Pages

-

Goulds 3198 i-FRAME

11 Pages

-

Goulds Trash Hog®

11 Pages

-

Goulds 3796

11 Pages

-

HT 3196 i-FRAME

14 Pages

-

Goulds 3400 Double Suction Pumps

11 Pages

-

Goulds API 3171

4 Pages

Archived catalogs

-

Goulds 3420 Double Suction Pumps

11 Pages

-

Goulds Model 3900

13 Pages

-

Medium Consistency Pump Systems

11 Pages

-

Goulds Model 3175

15 Pages

-

Goulds 3910

11 Pages

-

Goulds Model 5500

11 Pages

-

Goulds AF Axial Flow Pumps

11 Pages

-

Goulds Molten Sulfur Pumps

2 Pages