Catalog excerpts

The Worldwide Leader in Concrete Paving Technology

Open the catalog to page 1

First, our team of concrete paving specialists will study the submi ed plans for your waterway project and analyze your equipment needs. This involves top widths, bo om widths, percentage of slope on the walls, is the slope constant throughout the project, top to bo om length of the canal walls, distance of the canals, the number of variations in the proles, the presence of a haul road and berm, and anticipated concrete supply to the paver. The team will break down the concepts and provide practical recommendations on the choice of slipform concrete paver and mold considerations or paving...

Open the catalog to page 2

GOMACO’s quality management system is ISO 9001 and our products can be CE certied. Our manufacturing facility leads the concrete paving industry in computerization, robotics, and mechanization to provide precision from concept to nished product. The GOMACO manufacturing team is made up of three generations of personnel who build a product that has a worldwide reputation for quality, versatility, and dependability. Safety is the rst consideration in the design process and we go beyond regulations and requirements with your team’s well-being in mind. Highest Standards of Quality and Safety...

Open the catalog to page 3

Ail-American Canal The Ail-American Canal (located in Southern California, U.S.A.) was a concrete lining project which called for a new 37 kilometer (23 mi) long concrete lined canal to be built parallel to the existing unlined canal. Coffman Specialties paved the 9.7 kilometer {6 mi) long Reach Two and 6.4 kilometer (4 mi) long Reach Three of the project. The proposed lined sections would have slopes of 1.75:1 and 2:1, a bottom width of 15.2 meters (50 ft) and a top width spanning 45.7 meters (150 ft). Slope widths would be variable, between 11.4 meters (37.3 ft) and 14 meters (45.7 ft)....

Open the catalog to page 4

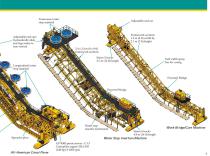

Transverse water stop material hydraulically slide true vertical Framework sections Full width spray Powered Wedge inserter mechanism Water Stop Insertion Machine Work Bridge/Cure Machine Ail-American Canal Paver

Open the catalog to page 5

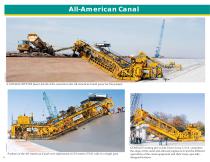

All-American Canal A GOMACO RTP-500 placer fed all of the concrete to the All-American Canal paver for this project. Portions of the All-American Canal were slipformed at 21.9 meters (72 ft) wide in a single pass. 6 GOMACO’s testing pier in Ida Grove, Iowa, U.S.A., simulates the slope of the canal and allowed engineers to test the dierent operations of the canal equipment and their many speciallydesigned features.

Open the catalog to page 6

Reels of blue water stop material are mounted to the paver and the material is fed down through brackets into an inserter mechanism mounted in the paving pan. The blue water stop material is being inserted into the concrete from the paver, which is creating the ongitudinal joints down the canal. paver and its capability to pave the full prism of a canal The water stop insertion machine follows the canal paver. The holes in the concrete are pockets created by workers on the paver notching out pieces of the water stop material, so the transverse water stop material will fit on top of the...

Open the catalog to page 7

Slipf arming Canals The sectional mold and front hopper feature different inserts to change the slope length and the depth. A sliding berm cap allows an extra 300 millimeters (11.8 in) of slope length adjustment on this An adjustable berm cap is available on the canal mold. The adjustable berm cap is attached to the pan and can be adjusted by sliding the mechanism up or down and then bolting it into place. A paver with a front-mounted chain trimmer slipforms a new canal between Amasya and Tasova in northern Turkey in a three-pass process.

Open the catalog to page 8

A chain trimmer on the front of the paver ne trims the grade as the canal is simultaneously poured allowing canal paving eciency. A work bridge has been a ached to the back of the paver allowing the crew to nish the concrete around the joints being scored into the side of the slope. Concrete is metered down the slope by an auger. A system of baes controls the concrete and keeps it from sliding down to the bo om of the canal. This paver is using 3D machine guidance for slipforming the concrete canal lining. 9

Open the catalog to page 9

Canal Paving with GOMACO The trapezoidal canal mold has the ability to pave a deeper and wider canal by adjusting the berm caps. 10

Open the catalog to page 10

The GOMACO paver is referencing stringline from inside the track line for the This four meter (13 ft) wide, 200 millimeter (8 in) thick canal in Japan was trapezoidal canal. slipformed in two paving passes. like before it is finished. This four-track GOMACO machine slipforms a water drainage channel below grade, around natural liquid gas storage tanks in South Wales.

Open the catalog to page 11

Various Applications with the Commander III The Commander III three-track paves a slo ed drain through the Perthus Tunnel between France and Spain. The Commander III three-track uses the simultaneous trim/ pour method to slipform the V-ditch. The Commander III uses the conveyor for fast delivery of concrete to the hopper, as it paves a waterway in Bulgaria. The Commander III three-track slipforms a V-ditch in India. 12

Open the catalog to page 12

Slotted Drains A view from on top of the 4400 looking down on a new slo ed drain in Mauritius. A four-track 4400 paves a 500 millimeter (19.7 in) slo ed drain in Mauritius. The Commander III three-track slipforms a slo ed drain in England. The Commander III paves a slo ed drain and drainage channel in Northern Ireland. 13

Open the catalog to page 13

Overview Of A Slope Extension Project Trimmed material was conveyed to the top of the slope with an onboard conveyor system and discharged on the berm just outside of the stringline. Two similar GOMACO machines were designed to trim and pave the slope extension in the southwestern United States.

Open the catalog to page 14

Paving With The GP - 4000 The GP-4000 trimmed and poured simultaneously and achieved excellent production results. The GP-4000 can pave widths up to 15.24 meters (50 ft).

Open the catalog to page 15

The GOMACO 4400 slipforms a left-side pour U-Channel 508 millimeters (20 in) tall, below grade, and next to an existing road in Mauritius. 16 The Commander III with a sidemounted mold paves a U-Channel in Brazil. This four-track GOMACO paver slipforms a U-Channel in France.

Open the catalog to page 16All GOMACO International catalogs and technical brochures

-

Texture/Cure Machines

8 Pages

-

GRD

4 Pages

-

T/C-5600

4 Pages

-

High-Production Screed

2 Pages

-

Cylinder Finishers Brochure

20 Pages

-

Commander III

4 Pages

-

GP-4000

28 Pages

-

GP-2600

16 Pages

-

GP-2400

12 Pages

-

GT 3200

8 Pages

-

GT 3600

24 Pages

-

G+ ConnectTM

3 Pages

-

GOMACO Full Line Brochure

40 Pages

-

Rail/Tunnel Application

12 Pages

-

Commander II

8 Pages

-

GT-3200 Sidewalk Paver

8 Pages

-

GT-3400 Sidewalk Trimmer

2 Pages

-

Commander III Trimmer

2 Pages

-

Commander III With IDBI

4 Pages

-

3300 Slipform Paver

8 Pages

-

G+ Remote Control

3 Pages

-

Xtreme Commander IIIx

4 Pages

-

GT-6300 Trimmer/Slipform paver

12 Pages

-

GT-6000 Trimmer/Paver

2 Pages

-

rail tunnel

12 Pages

-

GT-3200

12 Pages

-

GT-3400

16 Pages

-

GT-3600

24 Pages

-

Commander III

28 Pages

-

4400 Barrier paver

8 Pages