Catalog excerpts

Online Analysis AT-LINE STATION Extrusion Testing Platform real-time compliant material characterization Multifunctional • Melt index / Viscosity • Optical film inspection • Haze, Gloss • Film thickness since 1962 • Continuous measurement of the extrusion process • Die swell measurement, mel

Open the catalog to page 1

The Concept The At-Line Rheometer makes it possible to have continuous control of the polymerization process of pellets, fine granules or powder. Key rheological process information is generated continuously for possible close loop process automation based on the rheological characterization of material. This concept line consists of a combination of Online Rheometer, such as the MBR, SSR or RTR/RTS-TD and our EXTRUSIOMETER, that generates the melt. An optional raw-material feeding system (Online Sampler) ensures consistent material flow to the measurement apparatus to support the...

Open the catalog to page 2

AT-LINE STATION Film Testing Station for all applications AT-LINE STATION Set-up example EXTRUSIOMETER with Online-Sampler and Dosing Unit (1a) Measuring Head (RTR/RTS-TD, MBR, SSR) for determination of MFR, MVR, viscosity, ... External thermostat (temperature control) to regulate rolls from Coat hanger dies for films up to 400 mm 2-fold deflection rolls for smoothing or calender (3 rolls), roll width up to 420 mm Camera system to detect inhomogeneity and contamination Colour touch screen with operating Software „ROSWin“ for standalone usage Control and display draw off speed, draw off...

Open the catalog to page 3

The Concept Lab-Extruder GOETTFERT Lab-Extruders are stand-alone measurement instruments that is why we call them EXTRUSIOMETER! More than a half century of experience and continuous development with rheological analysis are incorporated in our line of extruders and rheological testing equipment. Different standard sizes are available, as well as user specified cylinder systems. The EXTRUSIOMETER may be equipped with multiple pressure transducers and temperature sensors, just one of the many important characteristics of the device. The liquid cooling system avoids the plastification of the...

Open the catalog to page 4

Film Analysis „Reflections“ on Rheology - transparent or maybe not... The continuous measurement of film thickness, gloss and detection of spots Film Thickness The laser distance measurement head operates with high precision, covering all the adjustable range. Its set-up can be optimized to cover a wide range of materials and surfaces. A simple Good/Bad analysis is available, also advanced functions, such as statistical analysis with averaging, min/max values and excentricity. Film Gloss Via the multi-angle gloss measurement, we cover the range from dull to high gloss. Using intelligent...

Open the catalog to page 5

AT-LINE STATION Rheometer Measuring Head Flat Film Unit optional with film analysis Blown Film Unit optional with film analysis EXTRUSIOMETER X-trude Series or Twin screw system Die Swell Measurement optional with melt cutting unit Filter Measuring Head Melt Tensile Measurement (RHEOTENS Online) As well as... - Continuous output measurement - Pelletizer - Strand Winder - Cooling Bath - Cable Sheating Die

Open the catalog to page 6

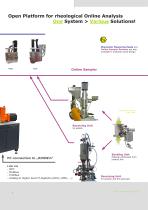

Open Platform for rheological Online Analysis One System > Various Solutions! Rheometer Measuring Heads and Online Sampler Systems are also available in explosion proof design. Online Sampler ... Material flow direction in any order ... Receiving Unit for pellets PC connection to „ROSWin“ Link via - OPC - Modbus - Profibus - Analog to higher level IT-Systems (DCS, LIMS, ...) Sending Unit Material withdrawal from product line Receiving Unit for powder and fine granule

Open the catalog to page 7

The Blown Film Unit AT-LINE Station - Downstream system options The Blown Film Station is a compact unit to blow, cool, draw-out and to wind up the extruded tubes. Primarily used in production quality control to measure how well the dispersion works in batches run on extruders and kneaders; in incoming quality control for color and spot distribution; in the development to find and control the max. draw-out of the polymer and to test the suitability of polymers and compounds used. Alternatively to produce small film tubes in different thicknesses, for applications mainly found in the...

Open the catalog to page 8

Material Feeding - Online Sampler Pellets, fine granules, powder, ... - steady from A to B! To ensure fully automated measurements of the AT-LINE STATION, the system can be designed by feeding out of a silo or hooked directly to the production. In both application cases a sample is taken by the Sending Unit and transferred by a carrier inert gas (e.g. nitrogen) to the Receiving Unit. Amplifier stations are available to make sure no material is stuck, if distances become too large. During the startup an optimization at site it is made sure that it runs perfectly year in, year out. Many soft-...

Open the catalog to page 9

Software One Software for all applications! ROSWin - multi functional Software for the control of all online measuring systems Rheo Online Software for Windows, in short ROSWin, is the user interface and visualization Software for all continuously working Online Rheometers and for the EXTRUSIOMETER. Attachable options are easily integrated. ROSWin runs on MS Windows® operating systems and is a stable platform for all our Online Rheometers and their options. Continuous development and testing in our R&D department, together with its numerous installations by customers worldwide, demonstrate...

Open the catalog to page 10

Power output Maximum torque Screw speed Cylinder geometries Screw back pressure Exchangeable bushing for powder and granules Rubber cylinder Cylinder tempering Variable numbers of pressure transducers Variable numbers of heating/cooling zones Variable numbers of melt temperature sensors Torque measurement Measure mode: constant speed / constant pressure Microsoft Windows® Software "ROSWin" Optional Add-On Systems and Follow Up Units • Fully automated material feeding (for powders, pellets or fine granules (Online-Sampler) • Metering, agitation and tamping mechanism • Round hole die, Slit...

Open the catalog to page 11All Göttfert Werkstoff-Prüfmaschinen catalogs and technical brochures

-

RubberView network

1 Pages

-

Meltindex

12 Pages

-

MINI BYPASS RHEOGRAPH MBR

12 Pages

-

Elastomer-Testing

12 Pages

-

TRICO-Ram

2 Pages

-

Elastomer Testing

12 Pages

-

Software -WinRheo2

1 Pages

-

Extrusiometer - X-TRUDE series

12 Pages

-

Melt Indexer MI - series

12 Pages

-

RHEOGRAPH 20 / 25 / 75 / 120

8 Pages

-

RemoteNet

1 Pages

-

Extrusiometer

12 Pages

-

Rheotens and Haul-Off

4 Pages

-

MI-Cleaning Boy

1 Pages

-

Online Rheometer

12 Pages

-

Rheograph 25E

1 Pages

-

TRICO RAM

2 Pages

-

Capillary Rheometers

8 Pages

-

GÖTTFERT

8 Pages

-

ELASTOGRAPH

12 Pages

Archived catalogs

-

MI-Series

12 Pages

-

rheometer

4 Pages

-

fully automatic rheometer

3 Pages