Catalog excerpts

PROCELL LABSYSTEM Spray granulation Spray Agglomeration Spray Coating Spray encapsulation powder layering Direct pelletization Glatt. Integrated Process Solutions.

Open the catalog to page 1

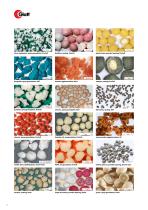

I— 1 mm —I micro organisms, spray granulation, ProCell fertilizer, coating, ProCell tomato, agglomeration, Vario fungicide, spray granulation, AGT vitamin, spray granulation, ProCell sauce powder, agglomeration, GF lavender oil, encapsulation, ProCell zeolite, direct pelletization, shovel rotor enzyme, coating, Vario I— 1 mm —I ceramic, spray granulation, AGT I— 1 mm —I catalyst, coating, ProCell I— 1 mm —I proteine, spray granulation, ProCell plastic foam, powder layering, ProCell PUFA, encapsulation, ProCell hollow spheres, powder layering, shovel rotor

Open the catalog to page 2

Technologies Solutions for your product ideas ProCell LabSystem Glatt Process Technology Food, Feed & Fine Chemicals offers The laboratory unit ProCell LabSystem is designed for testing of innovative technologies for a variety of applications such as spouted bed and fluid bed processes in the single kg-scale: for the food, animal feed, cosmetic, chemical or fine chemical »» Spray granulation: granules and pellets from liquids »» Spray agglomeration: granules from powder Our focus: development, optimization and processing of bulk »» Spray coating: coating of particles with liquids materials...

Open the catalog to page 3

standard system with Vario 3 insert TECHNICAL DATA spraying rate »» 0.2 –18 l/h (depending on product) air flow/inlet air temperature utility requirements »» weight: 1,300 kg »» main measurements refer to drawing

Open the catalog to page 4

Flexible UNIT: ProCell – Vario – GF – AGT – Rotor ProCell System »» continuous spouted bed: spray granulation and encapsulation »» batch spouted bed: ProCell 5- insert working volume: 0.4 – 4 l capacity: 0.2 – 2 kg/h ProCell 10 – insert working volume: 0.8 – 8 l capacity: 0.4 – 4 kg/h Vario System »» continuous fluid bed: spray granulation and encapsulation »» batch fluid bed: agglomeration, coating and Vario 3 - insert working volume: 2.5 – 10 l capacity: 0.4 – 4 kg/h Vario 7 - insert working volume: 10 – 38 l capacity: 1 – 10 kg/h Wurster coating GF System »» continuous fluid bed: spray...

Open the catalog to page 5

Product Flow in The ProCell LabSystem cleaning water cleaning water solid discharge spray liquid final product Standard configuration cyclone with dust recycling (incl. rotary valve) 13 external filter in lower part continuous discharge double-valve system 14 WIP system for internal process filter increased process air volume 500 m³/h 4 internal process filter increased inlet air temperature 300°C, 250 m³/h 5 spray nozzle (bottom-spray) 16 continuous volumetric powder feed 6 continuous discharge zig-zag-sifter 17 bypass inlet air heater closed loop process gas with condensation data...

Open the catalog to page 6

Modular configuration options: TAKE YOUR CHOICE external filter in lower part cartridge filter, internal process filter cyclone with rotary valve and dust recycling top spray two-way-nozzle, insulated (hot-melt) bag filter, internal process filter condenser, closed loop process top spray three-way nozzle nozzle with (left) /without (right) needle volumetric powder feed continuous product discharge/zig-zag-sifter spray pump Glatt. Integrated Process Solutions. 7

Open the catalog to page 7

Product Flow in The ProCell LabSystem Maximum operator flexibility Solid dosing The ProCell LabSystem made by Glatt is the most flexible When continuous dosing of solid raw material is desired, this laboratory fluid bed unit on the market. Integrated in a can be done by means of a screw feeder. mobile base unit, this modular lab all-rounder allows the use of all process options for batch and continuous fluid bed, Continuous discharge spouted bed or rotor processes for a great variety of material The zig-zag-sifter is not only discharging product from the process. The compressed air, which...

Open the catalog to page 8

SAFeTY ConCept: Standard And PRO-Design expansion chamber and filter housing in PRO-design ProCell LabSystem, PRO-design, Vario 3 - insert ProCell LabSystem designed for ... product vessel in PRO-design minimum ignition energy in the dust cloud at 200 °C > 3 mJ minimum ignition temperature (MZT) > 300 °C glowing temperature (thin layer ignition temperature) > 275 °C dusts shall be electrically conducting (specific resistance < 10 9 Ωm) dusts maximum explosion overpressure Pmax ≤ 11 bar maximum Kst value Kmax ≤ 400 bar*m/s hybrid mixtures: maximum explosion overpressure of dusts Pmax ≤ 10...

Open the catalog to page 9

Processes Spray granulation Liquids (solutions, suspensions, melts) are sprayed into the fluid bed. The process combines the drying respectively solidification of liquids and the granulation in a single step. There is no need for a separate feed of solid raw material. The granules are growing in layers homogeneously. Typical grain sizes: 50 µm - 4 mm. Spray encapsulation Embedding substances in matrix pellets. The substances to be protected are emulsified and then gently spraygranulated. Spray agglomeration Very small particles are fed to the fluid bed. Binder liquid is sprayed and wets the...

Open the catalog to page 10

Overview of operator advantages »» feasibility tests 500 g/batch - 4 kg/batch (batch mode) and 200 g/h - 4 kg/h (continuous mode) »» production of samples 1 kg/batch - 30 kg/batch (batch mode) and 1 kg/h - 15 kg/h (continuous mode) »» maximum flexibility for all processes and operating modes »» maximum flexibility for all material systems and future products »» high operator protection »» high environment protection »» simplified safety reviews prior to trials and productions »» mobility ProCell LabSystem, standard configuration, with Vario 3 insert Glatt. Integrated Process

Open the catalog to page 11

© Glatt Ingenieurtechnik GmbH. All rights reserved. Subject to errors and technical changes. BRO_PTF_105_ProCell-LabSystem_2018-05_EN Glatt Corporate Marketing.

Open the catalog to page 12All Glatt Ingenieurtechnik GmbH catalogs and technical brochures

-

FLUIDIZED BED SYSTEMS

24 Pages