Catalog excerpts

A REVOLUTIONARY TWISTING SYSTEM FOR BCF CARPETYARNS YARN WINDING & PROCESSING MACHINES

Open the catalog to page 1

CONVENTIONAL PROCESS SMART PROCESS Storage - Relaxation Tufting - Weaving Tufting - Weaving

Open the catalog to page 2

INLINE TWISTING FOR HEATSETTING CONVENTIONAL TWISTING AND HEATSETTING 2 operations NO singles twist Maximum Bulk Good Tip Definition 1 operation NO singles twist Maximum Bulk Good Tip Definition Multi-purpose twisting system for carpet BCF yarns; each module produces 2 ends of 2 ply or 2 ends of 3 ply yarn in 1 single step. Alternate twist direction S/Z with small tack point between the twisted zones. High speed twisting with maximum bulk and no singles twist. Twisting directly from extrusion packages, thereby avoiding intermediate storage and handling. Endless styling possibilities

Open the catalog to page 3

WORKING PRINCIPLE Tension - measurement Stage 2 Heatsetting Power-Heat-Set® Superba® Closed loop tensioners SmarTwist Accumulator > 25 min. capacity Closed loop tensioners 1st & 2nd end Tension - measurement Stage 1

Open the catalog to page 4

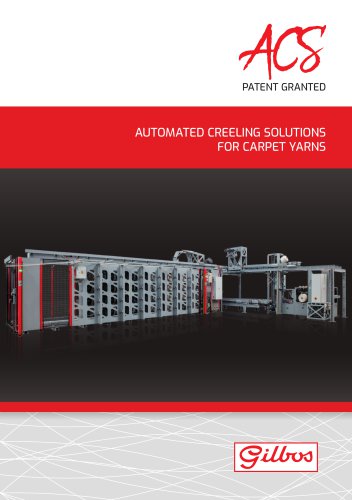

FEATURES EASY SWITCH FROM 2 TO 3 PLY YARNS RFID IN TWISTJETS TO GUARANTEE PROPER JET USE AND EASY CHANGE OF TWIST JETS CHARACTERISTICS OF THE SMARTWIST PROCESS Larger heatsetting creel, but no space for cablers required. 2 ends per finished package, so only half the take-up winder required. 2 ends per finished package, so 2 ends in each tufting needle. 2 ends in each tufting needle, so only half the tufting creel required. 2 ends per finished package, so no length differences and no yarn waste. No intermediate storage of cabled yar

Open the catalog to page 5

MACHINE AND PROCESS CONTROL BY MEANS OF THE HYPERION AND ORION SYSTEM 72 ENDS = 36 SMARTWIST MODULES SUPERBA® LAYOUT

Open the catalog to page 6

Human Interface Gilbos Machines The Gilbos Hyperion control system controls all the vital entanglement parameters such as speed, air pressure and yarn tension. Also the production parameters such as length, number of packages, production and efficiency are monitored by the Hyperion control system. All the parameters are stored on the Hyperion control system in easily adjustable recipes. Transferring recipes and adjusting machine configurations can be done within a matter of seconds. Access to the Hyperion control system is protected by passwords with different security levels. 48 ENDS = 24...

Open the catalog to page 7

TECHNICAL SPECIFICATIONS Count range Layout gauge Twisting speed Electrical supply Total connected load Machine and process control Hyperion and Orion control system GILBOS nv Grote Baan 10 BE-9310 Herdersem - Aalst Belgium Tel. +32 53 78 18 78 Fax +32 53 78 24 70 info@gilbos.com www. gilbos.com GILBOS of AMERICA, Inc. 1812 Antioch Road Dalton GA 30720 USA Tel. +1 706 529 3600 Fax +1 706 529 3595 info@gilbos.com www. gilbos.com All technical details, descriptions, illustrations, dimensions and other particulars in this brochure are given in good faith, and can be subject to change without...

Open the catalog to page 8All GILBOS catalogs and technical brochures

-

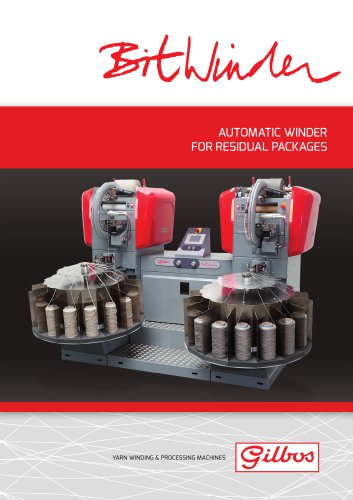

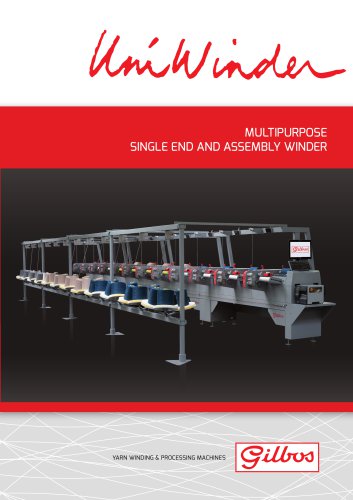

MULTIPURPOSE TAKE-UP WINDER

4 Pages