Catalog excerpts

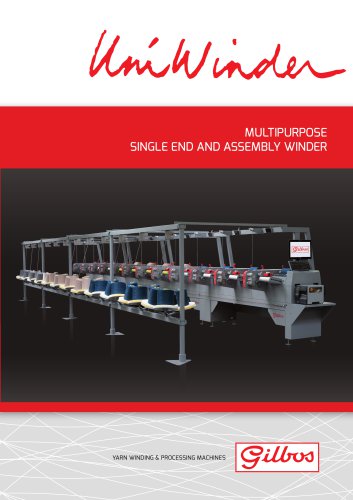

technical specifications Type of winding Winding speed (speed depending on process parameters) on cyclindrical tubes Ø 73 mm x 290 mm with freely programmable winding angle between 13° and 21° standard - 15 s cycle time - 8 tubes in magazine Traverse length Package diameter Package weight up to 12 kg or 26,5 lbs depending on the fiber material BCF, CF or spun - PES, PP, PA, natural fiber Count range gauge 800 or 1000 mm, 3 spindles per section Spindles, guides & feeder rollers individually driven and controlled by digital inverter Electrical supply Total connected load multipurpose Single end and assembly winder Machine and process control Hyperion and Orion control system developed by Gilbos GILBOS of AMERICA, Inc. 1812 Antioch Road Dalton GA 30720 USA Tel. +1 706 529 3600 Fax +1 706 529 3595 info@gilbos.com www.gilbos.com All technical details, descriptions, illustrations, dimensions and other particulars in this brochure are given in good faith, and can be subject to change without notice. Yarn Winding & Processing Machines GILBOS winding and processing machines for: Rewinding Rewinding + CMS Assembly winding AirEntangling AirTwisting SmarTwisting Heatset winding Yarn Winding & Processing Machines

Open the catalog to page 1

OPTIONS Conveyor belt Automatic Winder for single end and assembly winding • Conveyor belt at the rear side of the machine • Photocell to stop/start the conveyor. Brake plate UniWinder CMS - Creel Management System and package lift • Brake plateon the package. avoid that broken ends are wound with additional Creel Management System. • UniWinderwind packages for a specific carpet design Ability to • to a pre-determined length. • The input data is a csv-file created by any leading Carpet Design Software package, containing the length and yarn type for each position in the creel. Optimal use...

Open the catalog to page 2

OPTIONS Conveyor belt Automatic Winder for single end and assembly winding • Conveyor belt at the rear side of the machine • Photocell to stop/start the conveyor. Brake plate UniWinder CMS - Creel Management System and package lift • Brake plateon the package. avoid that broken ends are wound with additional Creel Management System. • UniWinderwind packages for a specific carpet design Ability to • to a pre-determined length. • The input data is a csv-file created by any leading Carpet Design Software package, containing the length and yarn type for each position in the creel. Optimal use...

Open the catalog to page 3

technical specifications Type of winding Winding speed (speed depending on process parameters) on cyclindrical tubes Ø 73 mm x 290 mm with freely programmable winding angle between 13° and 21° standard - 15 s cycle time - 8 tubes in magazine Traverse length Package diameter Package weight up to 12 kg or 26,5 lbs depending on the fiber material BCF, CF or spun - PES, PP, PA, natural fiber Count range gauge 800 or 1000 mm, 3 spindles per section Spindles, guides & feeder rollers individually driven and controlled by digital inverter Electrical supply Total connected load multipurpose Single...

Open the catalog to page 4All GILBOS catalogs and technical brochures

-

MULTIPURPOSE TAKE-UP WINDER

4 Pages