Catalog excerpts

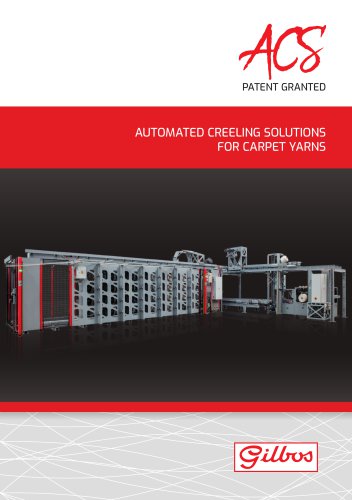

AUTOMATED CREELING SOLUTIONS TECHNICAL SPECIFICATIONS TAKE PACKAGE FROM PALLET/CONTAINER On demand for multiple headset systems of 1 to 6 belts Number of packages per hour AUTOMATED CREELING SOLUTIONS FOR CARPET YARNS Count range PATENT GRANTED 240 per feed robot 120 for 1 preparation deck 240 for 2 preparation decks 240 per carrier – lift PREPARATION STATION FINDS TAIL & LEADING END 120 per creel robot Air consumption Package dimensions Electrical supply Full carrier Package weight Machine and process control PREPARED PACKAGE IS PLACED IN CARRIER & CONVEYED TO ROBOT Hyperion and Orion control system CREEL ROBOT REMOVES CARRIER WITH EMPTY PACKAGE GILBOS winding, processing machines & package handling Rewinding Assembly winding AirEntangling AirTwisting Heatset winding Automated package handling GILBOS of AMERICA, Inc. 1812 Antioch Road Dalton GA 30720 USA Tel. +1 706 529 3600 Fax +1 706 529 3595 info@gilbos.com www.gilbos.com All technical details, descriptions, illustrations, dimensions and other particulars in this brochure are given in good faith, and can be subject to change without notice. CREEL ROBOT PLACES CARRIER WITH FULL PACKAGE IN THE CREEL & SPLICES THE ENDS PACKAGES TO HEATSET OR WARPING YARN WINDING & PROCESSING MACHINES PACKAGE HANDLING MACHINES

Open the catalog to page 1

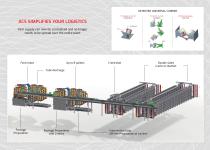

PATENTED UNIVERSAL CARRIER CONVENTIONAL PROCESS AUTOMATED CREELING SOLUTIONS 1 / Package on carrier Preparation ACS SIMPLIFIES YOUR LOGISTICS 2/ Carrier to creel Transport Operator takes package Operator places package in creel Operator splices yarn ACS takes, prepares, places and splices yarn Yarn supply can now be centralized and no longer needs to be spread over the entire plant Heatsetting/Tufting process Operator removes empty package > 100 % labor time > Ergonomic issues Heatsetting/Tufting process ACS removes empty package > No labor required > No ergonomic issues > Handling packages...

Open the catalog to page 2

PATENTED UNIVERSAL CARRIER CONVENTIONAL PROCESS AUTOMATED CREELING SOLUTIONS 1 / Package on carrier Preparation ACS SIMPLIFIES YOUR LOGISTICS 2/ Carrier to creel Transport Operator takes package Operator places package in creel Operator splices yarn ACS takes, prepares, places and splices yarn Yarn supply can now be centralized and no longer needs to be spread over the entire plant Heatsetting/Tufting process Operator removes empty package > 100 % labor time > Ergonomic issues Heatsetting/Tufting process ACS removes empty package > No labor required > No ergonomic issues > Handling packages...

Open the catalog to page 3

AUTOMATED CREELING SOLUTIONS TECHNICAL SPECIFICATIONS TAKE PACKAGE FROM PALLET/CONTAINER On demand for multiple headset systems of 1 to 6 belts Number of packages per hour AUTOMATED CREELING SOLUTIONS FOR CARPET YARNS Count range PATENT GRANTED 240 per feed robot 120 for 1 preparation deck 240 for 2 preparation decks 240 per carrier – lift PREPARATION STATION FINDS TAIL & LEADING END 120 per creel robot Air consumption Package dimensions Electrical supply Full carrier Package weight Machine and process control PREPARED PACKAGE IS PLACED IN CARRIER & CONVEYED TO ROBOT Hyperion and Orion...

Open the catalog to page 4

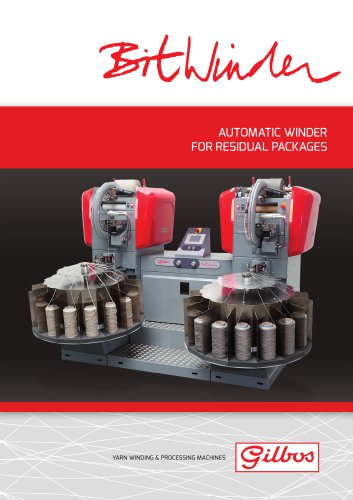

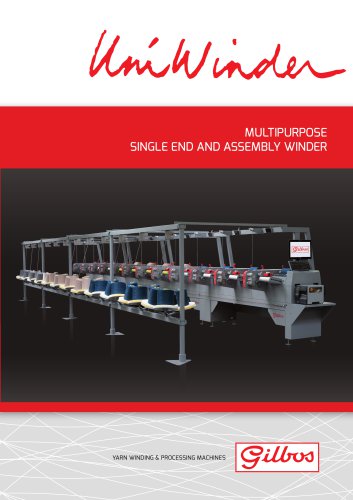

AH technical details, descriptions, illustrations, dimensions and other particulars in this brochure are given in good faith, and can be subject to change without notici GILBOS winding, processing machines & package handling Rewinding Assembly winding AirEntangling AirTwisting Heatset winding Automated package handling GILBOS of AMERICA, Inc. 1812 Antioch Road Dalton GA 30720 USA Tel. +1 706 529 3600 Fax +1 706 529 3595 info@gilbos.com www.gilbos.com YARN WINDING & PROCESSING MACHINES PACKAGE HANDLING MACHINES

Open the catalog to page 5All GILBOS catalogs and technical brochures

-

MULTIPURPOSE TAKE-UP WINDER

4 Pages