Catalog excerpts

OPERATION TERMINAL FOR THE FOOD INDUSTRY Customized solutions Splash water protected operation terminal for Wernesgrüner Brauerei GmbH TASK DEFINITION PROJECT DESCRIPTION PROJECT DATA The German export-oriented brewery Wernesgrüner Brauerei GmbH is an inherent part of the brewery group Bitburger Braugruppe. In order to guarantee an efficient flow of information and goods between the five brewery locations (Wernesgrüner, Bitburger, Köstritzer, Licher and König Pilsener), a standard ERP system is relied on throughout the group. Data collection portals in the different product divisions support in real time the demand-oriented planning. Against the background of the specific hygiene requirements in the microbiologically sensitive filling area, Wernesgrüner Brauerei approached GETT Gerätetechnik with a request to develop an operation terminal customized to their specifications. The essential criteria of the specification sheet incorporated the safe operation even in case of a high degree of humidity and effect of splash water, as it can be expected in case of regular intermediate and final cleaning using foaming agents and in application of high-pressure cleaners. A mobile solution should be found during the implementation; a solution that resorts to the standard components used within the brewery group and positively influences the availability of spare parts this way. The following presented technical parameters refer exclusively to the application modalities customized for Wernesgrüner Brauerei and should solely serve as an exemplary representation of the client-specific service range of GETT Gerätetechnik. The most different technologies will be combined according to the case of application; these technologies will be defined in a shared dialogue on the basis of the continuously growing range of in-house data input components on the grounds of the client‘s wishes. The project volume comprised the complete design and included the following components: Casing Design in stainless steel, splash water protected according to IP65, frontal glass pane, openable by means of two padlocks, laterally assembled switch to start the terminal, fixation on movable frame Frame Powder-coated, four transport rollers at the foot end, two of them with locking function Operation unit Splash water protected (IP65) membrane keypad with 50-mm built-in trackball, permanently installed in the casing, short-stroke key version for tactile writing experience, foil printing according to GETT standard Display type Standard monitor with 22“ screen diagonal, simple enclosure installation, humidity-protected arrangement behind glass Data processing unit Thin Client PC Connections/Exits 220 V electric supply, Ethernet network interface, splash water protection according to IP65 standard (all connections in casing frame led to the floor level) SPECIFIC CHALLENGES Mobile multi-shift operation, regular plant cleaning by means of foaming and high-pressure cleaners, corrosive environmental conditions, reliable data export Client: Wernesgrüner Brauerei GmbH Industry: food and beverage industry Product: splash water protected operation terminal Application: entry of production-relevant data for evaluation in superordinate ERP system Keypad: splash water protected short-stroke keypad with integrated trackball Frames / rollers: corrosion-resistant design (tolerance against chloride-containing cleaning and disinfection agents) GETT Gerätetechnik GmbH Mittlerer Ring 1 08233 Treuen Phone: Fax: E-Mail: Internet:

Open the catalog to page 1All GETT Gerätetechnik GmbH catalogs and technical brochures

-

Gateway wireless

1 Pages

-

Gateway corded

1 Pages

-

TKV-084-FIT-TOUCH-IP65-MGEH

2 Pages

-

TKH-TOUCHB-MODUL

3 Pages

-

TKS-030C-TOUCH-KGEH

2 Pages

-

TKS-030C-TOUCH-MODUL

2 Pages

-

TKS-030c-KGEH

1 Pages

-

TKS-030C-MODUL

1 Pages

-

TKS-105c-TOUCH-KGEH

2 Pages

-

TKS-105c-TB38-FP-4HE

2 Pages

-

TKS-105C-KGEH

1 Pages

-

TKS-105C-FP-4HE

2 Pages

-

TKS-105c-MODUL

3 Pages

-

TKS-104c-KGEH

1 Pages

-

TKS-104C-MODUL

1 Pages

-

TKS-088c-TOUCH-MODUL

3 Pages

-

TKS-088c-TB38-KGEH

1 Pages

-

TKS-088c-TB38-MODUL

2 Pages

-

TKG-107-TOUCH-IP68-BLACK

2 Pages

-

TKG-106-IP68-BLACK

1 Pages

-

TKG-086-IP68-BLACK

1 Pages

-

TKF-085b-MODUL

2 Pages

-

TKL-103-LH-KGEH-WHITE

1 Pages

-

TKR-103-TOUCH-ADH

5 Pages

-

TKG-083b-TOUCH-MODUL

3 Pages

-

TKG-083b-TB38-MODUL

2 Pages

-

TKG-083b-MODUL

1 Pages

-

TKG-105-IP68-BLACK

1 Pages

-

TKG-105-MED-IP68-BLACK

1 Pages

-

TKF-085b-TOUCH-MODUL

3 Pages

-

TKF-085c-TOUCH-MGEH

2 Pages

-

TKS-088c-TOUCH-SCHUBL

3 Pages

-

TKS-105c-TOUCH-MODUL

3 Pages

-

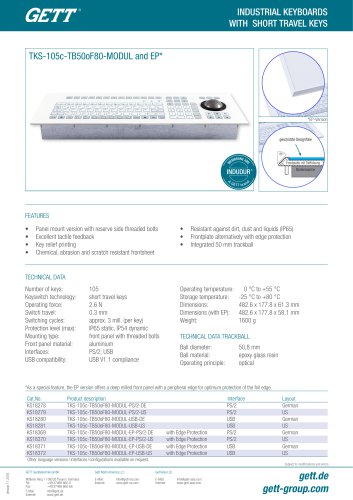

TKS-105c-TB38-MODUL and EP*

3 Pages

-

TKS-105c-TOUCH-KGEH

2 Pages

-

CK4W

3 Pages

-

CLEANKEYS CK4 KEYBOARD

2 Pages

-

KR23210

3 Pages

-

GETT_KL15263

1 Pages

-

CK_Datasheet_CKM2W

1 Pages

-

KL20232

2 Pages

-

Flyer TKV-084-FIT

2 Pages

-

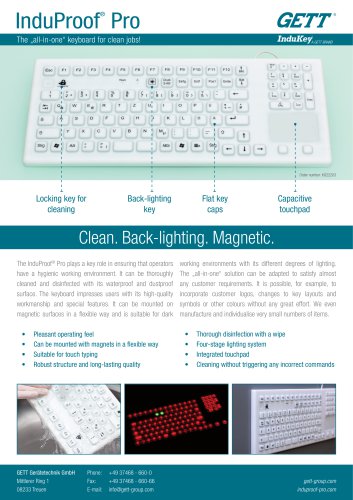

Flyer Induproof Pro

2 Pages

Archived catalogs

-

TKS-105C-TB38-KGEH

1 Pages

-

TKS-088c-TOUCH-KGEH

2 Pages

-

KH20225

1 Pages

-

Flyer Smart Clinical Board

2 Pages

-

Indukey catalogue 2013

104 Pages

-

InduKey_2012_HQ

104 Pages

-

InduKey Catalogue

72 Pages