Catalog excerpts

Throughput of a thousand kilos and more GETECHA heavy-duty granulators

Open the catalog to page 1

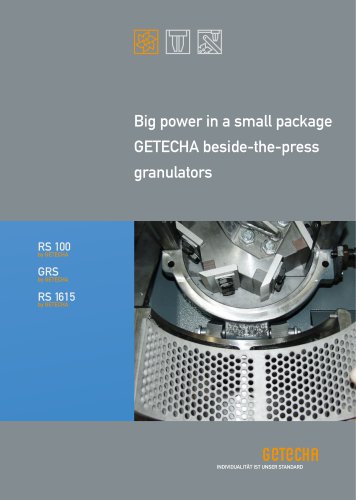

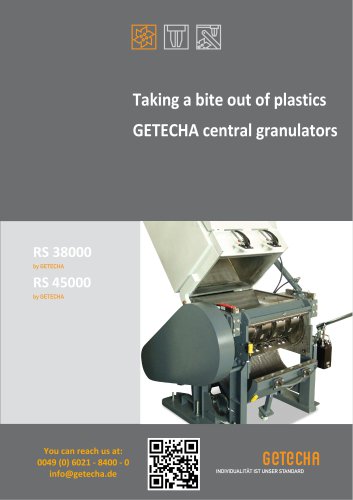

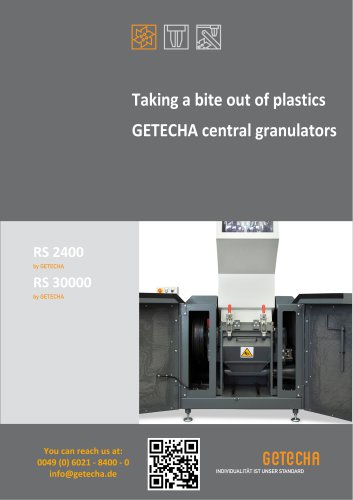

Choose the system partner who is also a competent dialogue partner: GETECHA. For more than five decades, we have been acting as consultants to the plastics processing industry, developing, planning, and manufacturing consistently individual solutions from sprue recovery and automation systems to granulation. We have been supporting many of our customers for a very long time already. We simply feel at home with your challenges. Individualität ist unser Standard. True greatness, tailor-made The successful central granulator for all areas of plastic granulation. Unbeatable when it comes to...

Open the catalog to page 2

Even more of everything, for everything The biggest of the big. When tonnage is what counts, the RS 8000 is the granulator of choice. Equipped with an automatic feed system and granulate transport, it becomes a high-performance granulating center. A high level of the automation simplifies maintenance and ensures high economy. “Want to go a number higher?” • Segmented frame rotor ensures optimal distribution of cutting forces, ideal intake behavior and a low noise-level • Thick-walled stock outages and hollow shapes are seized flawlessly Easy to clean • Hopper and screen cradle open and...

Open the catalog to page 3

Projects realized by GETECHA Granulation of blow-molded forms made of highly viscous and sticky plastic Requirements: Granulation of fuel containers, flash and starting tubes made of COEX. The temperature of the material that is to be granulated exceeds 150 °C, i.e., the plastic is highly viscous and sticky. When designing the granulator, it is a matter of ensuring sufficient capacity in terms of throughput so that nothing sticks inside the grinding chamber. For storage, the granulate must be cooled to at least 80 °C in order to avoid melting together here, as well. Our solution: A...

Open the catalog to page 4

Technische Daten: Technical specifications: Modell Model Rotor cutting diameter Hopper opening Cutting chamber opening Cutting length No. of rotary blades No. of stationary blades Type of cutting Rotor revolution Motor power, standard Screen size, standard Throughput Electrical connection Painting Model Modell Rotor cutting diameter Hopper opening Cutting chamber opening Cutting length No. of rotary blades No. of stationary blades Type of cutting Rotor revolution Motor power, standard Screen size, standard Throughput Electrical connection Painting 600 mm 625 x 830 mm 600 x 795 mm 600 mm 3x2...

Open the catalog to page 5

Granulation Beside-the-press granulators Central Granulators Heavy-Duty Granulators Automation Sprue removal Handling systems Special automation solutions Technical installations Development Manufacturing Start of operation GETECHA granulators granulate plastics and return them to the production cycle. The granulators can be expanded into stand-alone recycling systems. GETECHA realizes tailor-made, turnkey automation systems right around injection moulding machines. They are your onestop source for development, manufacturing, service and training. GETECHA have a worldwide sales and service...

Open the catalog to page 6All GETECHA catalogs and technical brochures

Archived catalogs

-

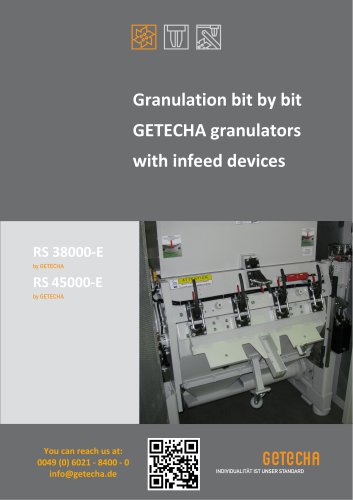

RS 38000-E RS 45000-E

2 Pages

-

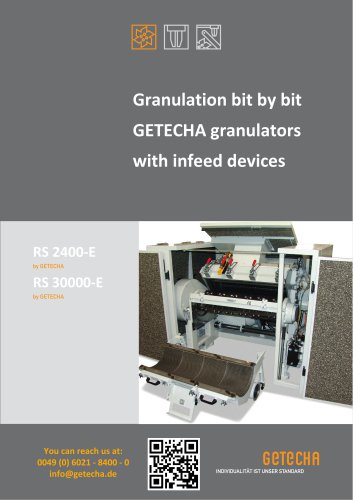

RS 2400-E RS 30000-E

2 Pages