Catalog excerpts

Like any other industrial valve steam traps are subject to wear and their correct functioning can be impaired by precipitated solids and dirt deposits. To assess the performance of a steam trap the following questions have to be answered: • Does the steam trap work properly? • If not, does the faulty trap cause a loss of steam (leakage) or banking-up of condensate (obstructed discharge p assage)? Faulty steam traps are a major source of waste in a steam distribution system. A trap that is blowing live steam is the worst offender, but traps that are plugged or stuck closed can also be costly. The decreased plant efficiency due to loss of energy and additional make-up water results in lost production. Furthermore, an increase of pressure is liable to arise in condensate systems which will lead to d ifficulties at all locations where condensate is discharged. The magnitude of such a steam loss depends on the cross-sectional area of the leak and, at the same time, the amount of discharged c ondensate. Locations where only small amounts of condensate are formed and discharged, e. g. drainage points in steam lines and tracing systems, are particularly problematical. On the other hand, locations where relatively large amounts of condensate are discharged will not give rise to considerable loss of live steam because of the presence of a large volume of liquid. Steam traps which are obstructed or stuck closed do not cause loss of energy and/or water but reduce – to a greater or lesser extent – the efficiency of heat-transfer equipment and steam users. And waterhammer caused by condensate banking-up leads to considerable p hysical damage in steam and condensate systems. Experience shows that installations where no regular trap testing and servicing takes place have a failure rate of defective steam traps in the order of 15 – 25 %. Regular maintenance and trap testing, which should be carried out at least once a year, can strongly reduce the f ailure rate to 5 %. Level meters use conductivity to monitor steam trap performance. A test chamber with an integral level electrode is installed upstream of the trap to detect any defective steam trap. The corresponding output signal is displayed by the Remote Test Unit NRA 1-3x (remote monitoring). The system VKE can monitor all types and makes of steam traps to detect loss of live steam. The correct operation of RHOMBUSline steam traps type BK 45/46, MK 45, UBK 46 can be verified by using the c ompact-type level probes NRG 16-19, NRG 16-27 and NRG 16-28. The test station NRA 1-3x will evalute the data coming from the system VKE. Another way to test traps is to use an ultrasonic listening device which detects the sound produced by steam flowing through the traps. Depending on the test system used the sound sensed by the device is either graphically represented in the form of a curve (VKP 40) or i ndicated by the deflection on the scale of a meter (VKP 10). When using the VKP 10, the field data specialist has to assess the i ndicator deflection and, consequently, the operation of the steam trap. The VKP 40, however, can directly track leaks associated with faulty steam traps and provides comprehensive reporting and a complete trap survey history. Annual costs caused by steam loss Number of steam traps installed Annual failure rate (Empirical value with first check approx. 15 – 25 %) A Number of defective steam traps B Steam loss per steam trap (kg/h) C Annual operating hours D Annual steam loss (kg) E Cost of steam per ton F Annual loss in EURO Example Test Systems Steam traps can be tested during operation by using sightglasses, ultrasonic listening devices or level meters. Sightglasses (Vaposcopes Type VK 14, VK 16) provide an effective means of observing the flow of liquids in pipework. They are installed upstream of the traps, and allow the assessment of the traps by making their operation visible. A satisfactory trap installation must pass all the water that flows to it without discharging live steam and must not be rendered inoperative by particles of dirt or by an accumulation of air. A Number of defective steam traps B Steam loss per steam trap C Annual operating hours D Annual steam loss By the way: A new steam trap costs – depending on the end connection – only approx. e 160 to e 200. Testing Steam Traps

Open the catalog to page 1

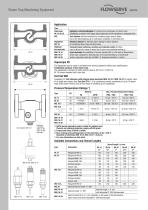

Steam Trap Monitoring Equipment Application Type Vaposcope VK 14, VK 16 VKE Vapophone VKP 10 TRAPtest VKP 40/VKP 40Ex Sightglass mit Borosilikatglas for checking heat exchangers and steam traps (installation up-stream of the traps). Visual supervision of flow conditions in condensate lines. Test chamber with level electrode for monitoring steam traps to detect loss of live steam/banking-up of condensate. Installation in horizontal lines. Ultasonic detector for detecting steam leakage in steam systems; for monitoring steam traps and stop valves. Computer-based monitoring, recording and...

Open the catalog to page 2

Steam Trap Monitoring Equipment System VKE Remote monitoring with Universal Test Chamber* TE Screened cable max. 50 m long Screened cable max. 50 m long Remote monitoring Rhombusline* Test station NRA 1-3 Test station NRA 1-3 max. 16 test chamber VKE 16-1/16A max. 16 steam traps type Rhombusline, e.g. MK 45-1 or BK 45 Alarm Electrode NRG 16-28 * Combination possible Vapophone VKP 10 The VKP 10 is used to detect sound in the ultrasonic range as caused by flowing steam through a steam trap. The ultrasonic vibrations are detected by a probe and converted into electric signals which are...

Open the catalog to page 3All GESTRA AG catalogs and technical brochures

-

STEAM-TRAP-MONITORING

2 Pages

-

BAE46-47

2 Pages

-

BK35A7-MK35A7-DK36A7

2 Pages

-

VKP40PLUS

2 Pages

-

MPA46

2 Pages

-

HERZLICH-WILLKOMMEN

2 Pages

-

GESTRA-INFORMS-UNA45-46-46A

2 Pages

-

STEAMTRAPS-BROCHURE

24 Pages

-

ZK-FLYER

7 Pages

-

FLYER-SPECTORMODUL

2 Pages

-

FLYER-NRGS15-1-LRGS15-1

2 Pages

-

CONTROL-VALVES-ZK

26 Pages

-

CHECK-VALVES

28 Pages

-

Thermodynamic Steam Traps DK

2 Pages

-

NAF

2 Pages

-

UNA

5 Pages

-

Control Valves ZK

4 Pages

-

Ball-Float Traps UNA

5 Pages