Catalog excerpts

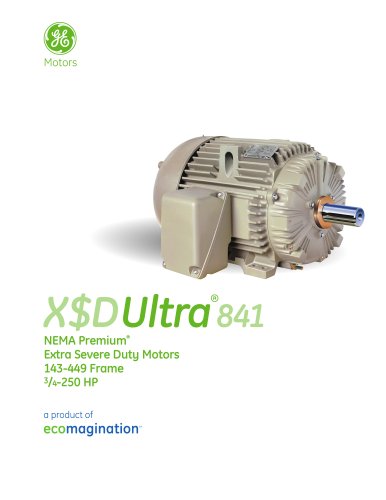

X$D Ultra 841 IEC Extra Severe Duty Motors (IP55) ®

Open the catalog to page 1

Expect More From Your GE Motor GE’s X$D Ultra® 841 IEC motors build on more than 20 years of industry experience in extra severe duty motor applications. They are specifically designed with features that meet or exceed the intent of IEEE 841-2009, the “gold standard” for the petrochemical and process industries. • Inverter duty capability • GEGARD2400™ insulation system • Six Star Bearing System™ • Low vibration / provisions for vibration monitoring • Low Class B temperature rise • Cast iron construction • 5 Year Warranty • 4-point Cast-in lifting lugs • Extended grease fittings What is the...

Open the catalog to page 2

Get More For Your Application Maximizing your investment means getting the most from the motors you choose. More than just getting the job done, motors must be dependable, rugged and built to last. Your application demands the best, and GE delivers. • Petrochem / Oil & Gas • Utilities & Power Generation • Pulp & Paper • General Process Industries • Fans, Pumps • Compressors, Conveyors • And many others • The steel reinforced recessed slinger, integrated into the drive end and non-drive end, ensures IP55 protection of the bearing system. • Low temperature rise designs help increase bearing...

Open the catalog to page 3

X$D Ultra 841 IEC Motors Built To A Higher Standard Six Star Bearing System™ Bearings, the life force of a motor, are what keep the X$D Ultra 841 IEC running smoothly. These features protect and lubricate the bearings, adding to the durability and longevity of the X$D Ultra 841 IEC. • Oversized bearings on both ends of the motor offer optimum performance. • Cast-iron bearing caps with gaskets retain lubrication and protect the bearing system from contaminants. • Safer lifting is possible with a four point lifting system versus a single eyebolt. Cast-in lifting lugs eliminate eyebolts that...

Open the catalog to page 4

Severe Duty Construction Gives More Assurance The X$D Ultra 841 IEC has a rugged, all cast iron construction with corrosion resistant ISO Grade 8.8 metric hardware. A recessed steel reinforced neoprene slinger is used on both the drive end and opposite drive end for better protection from outside elements and ensures IP55 protection. Terminal block and bronze ground terminal inside the terminal box provides quick and easy connection of the lead wires to the connection block with removable gland plate. Oversized, gasketed IP-56 conduit box with lead separation gasket and conduit box cover...

Open the catalog to page 5

Premium Energy Efficient Motors Deliver More Bottom Line Savings IE3 Premium Efficiency One of the greatest benefits of the X$D Ultra 841 IEC is its efficiency rating. X$D Ultra 841 IEC motors exceed all IE3 minimum guaranteed efficiency levels and GE guarantees the minimum efficiency levels stamped on the nameplate. In addition to meeting the IE3 Premium Efficiency Standards, the X$D Ultra 841 IEC motors meet World Zone 2, which includes ATEX, IEC Ex Zone 2 and Class 1, Div. 2, CE Mark.The GE Premium Efficiency design lowers annual energy cost and extends motor life without any sacrifice...

Open the catalog to page 6

GE Reliability Means More Uptime Operation Insulation System GEGARD2400™ insulation systems feature Class H insulation materials and exceeds IEC TS 60034-25 requirements by 60% at 400V. All motors are 100% tested to verify the corona inception voltage prior to shipment. • Trickle treat varnish system provides a reliable and consistent encapsulation of the stator winding and utilizes a fully automated computer controlled process. • Low temperature rise designs provide more thermal margin than industry-standard designs and maximize the bearing and winding life of the motors. Optional AEGIS...

Open the catalog to page 7

Access has never been easier! Motor Catalog View updated information about standard motors on your mobile device. It can also be viewed offline and printed. Find a distributor. Download datapacks. Access support library. Type keyword “gemotorswolong” News Follow us on LinkedIn The latest developments, new product introductions and special industry events. X$D Ultra®, GEGARD2400™, and Six Star Bearing System™ are trademarks of General Electric Company.© 2012 General Electric Company. All rights reserved. GEA18014B (

Open the catalog to page 8All GE Motors catalogs and technical brochures

-

Stock Inventory DC Motors

1 Pages

-

MD800 Armored Mill Motor

6 Pages

-

Buyers Guide

174 Pages

-

Oil & Gas

8 Pages

-

XSD Ultra®

4 Pages

-

Quantum® LMV

4 Pages

-

Mining and Minerals

8 Pages

-

XSD Ultra® 661

4 Pages

-

X$D Ultra® 841

4 Pages

Archived catalogs

-

MV7000 Flat Pack (FP)

16 Pages

-

Power Conversion

91 Pages

-

LV 7000-6 and 8

2 Pages

-

case study

1 Pages

-

MV7-Series

5 Pages

-

N37

12 Pages

-

D_Harnessing the Power of Wind

20 Pages

-

SVC and STATCOM fact sheet

4 Pages

-

Low Voltage Motors

8 Pages

-

MV6 Medium Voltage Drive

20 Pages

-

LV 7000 Drives

4 Pages

-

Generators Brochure

16 Pages

-

X$D Ultra 841 VSS

6 Pages

-

DC2100e

4 Pages

-

Genuine Parts

6 Pages

-

Synchronous Hydro Generators

10 Pages

-

ProSolar Power Station

3 Pages

-

A new direction for DP

12 Pages

-

Energy $aver

2 Pages

-

X$D Ultra ? 841 VSS

6 Pages

-

MV7000

16 Pages

-

MV4 Series

9 Pages

-

Onduleur Central ProSolar

3 Pages

-

A$DUltra

2 Pages

-

GEA18201A X$D IEC

6 Pages

-

AC and DC Excavator Solution

12 Pages

-

Series 9000-RCM

2 Pages

-

Motors Product Line Brochure

8 Pages

-

2008 Standard Products Catalog

248 Pages

-

GE Motors - Product Line

6 Pages