Catalog excerpts

Series 9000-RCM Large Synchronous Reciprocating Compressor Motor The Series 9000-RCM electrical design is based on I EC or NEMA standards. The mechanical design is based on International standards including ISO, ANSI, and CSA. These motors are built to API 546 Standards, meeting structural and testing requirements. In hazardous areas, NFPA and I EC standards Series 9000-RCM motors are specifically designed for reciprocating compressor drives in the petrochemical industry. Fast Commissioning • Shipped fully assembled when requested to minimize installation time • Self-enclosed, sturdy frame and core design • Purged and pressurized for hazardous locations • Soleplates available for easy alignment • Factory-proven no load running tests • GE designed, manufactured and tested excitation control systems • Optional rotor telemetry system providing world-class Easy Maintenance • A proven design that allows for easy maintenance and accurate alignment without any major disassembly • Improved environmental protection eliminates the need for multiple enclosure seals • Additional maintenance features are available to allow form wound coils ore used for medium and high voltage stotors. A modularized pre-wound core design provides superior strength and rigidity to the stator assembly. Stator laminations are precision punched from high-quality low loss electrical sheet steel that are coated with a thermally-stable insulation film (C5 coating) to minimize eddy current losses. accurate alignment outside the frame. The core is clamped under high uniform pressure to provide stiffness. The resulting assembled stator core has superior strength and rigidity, which promotes quiet performance, long life and trouble free operation. Low speed synchronous rotors are simple in design and rugged in designs typically include a forged steel shaft along with a fabricated steel hub, pole and winding. The rim diameter and thickness is selected to suit the inertia requirements as well as to mechanical design plays a critical role in achieving high technology provides high

Open the catalog to page 1

Ventilation & Enclosures meet the electrical and mechanical performance requirements of the designs. Extra inertia can be added as required to meet the specified current pulsation limit. The field windings are optimized to suit the application utilizing rectangular copper wire or copper strip—all provided with our well-proven Class F insulation system. The amortisseur winding design, a key to reliability, is also optimized to suit the specific starting The fabricated steel plate stator frame consists of two or more side plates continuously welded to the wrapper plates and rectangular steel...

Open the catalog to page 2All GE Motors catalogs and technical brochures

-

Stock Inventory DC Motors

1 Pages

-

MD800 Armored Mill Motor

6 Pages

-

Buyers Guide

174 Pages

-

Oil & Gas

8 Pages

-

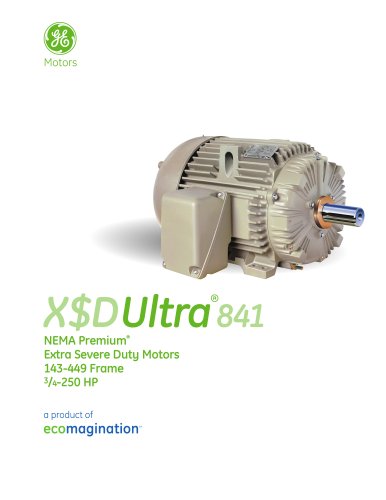

XSD Ultra®

4 Pages

-

Quantum® LMV

4 Pages

-

Mining and Minerals

8 Pages

-

XSD Ultra® 661

4 Pages

-

X$D Ultra® 841

4 Pages

-

X$DUltra® 841 IEC

8 Pages

Archived catalogs

-

MV7000 Flat Pack (FP)

16 Pages

-

Power Conversion

91 Pages

-

LV 7000-6 and 8

2 Pages

-

case study

1 Pages

-

MV7-Series

5 Pages

-

N37

12 Pages

-

D_Harnessing the Power of Wind

20 Pages

-

SVC and STATCOM fact sheet

4 Pages

-

Low Voltage Motors

8 Pages

-

MV6 Medium Voltage Drive

20 Pages

-

LV 7000 Drives

4 Pages

-

Generators Brochure

16 Pages

-

X$D Ultra 841 VSS

6 Pages

-

DC2100e

4 Pages

-

Genuine Parts

6 Pages

-

Synchronous Hydro Generators

10 Pages

-

ProSolar Power Station

3 Pages

-

A new direction for DP

12 Pages

-

Energy $aver

2 Pages

-

X$D Ultra ? 841 VSS

6 Pages

-

MV7000

16 Pages

-

MV4 Series

9 Pages

-

Onduleur Central ProSolar

3 Pages

-

A$DUltra

2 Pages

-

GEA18201A X$D IEC

6 Pages

-

AC and DC Excavator Solution

12 Pages

-

Motors Product Line Brochure

8 Pages

-

2008 Standard Products Catalog

248 Pages

-

GE Motors - Product Line

6 Pages