Catalog excerpts

Large Synchronous Machines > Up to 15,000 VoltsUp to 100,000 HP (75,000 kW) 4 Pole and Above Motors and Generators size="-1">

Open the catalog to page 1

GE Motors has the capability to design and manufacture electrical rotatingmachines up to 100,000 HP, and have supplied over 800,000 HP of motors for variable speed applications. This century of achievement has built a rich tradition of technical excellence, quality and reliability. > GE has the capability to design electrical rotating machines that comply with global standards and certifications, including but not limited to NEMA, IEC, API, Lloyds, ABS, ATEX and PTB. Imperial (english) or metric systems compliant components are available per customer specification. Our manufacturing...

Open the catalog to page 2

Weather Protected Enclosure(WPI, WPII, IP24, IC-01)Totally Enclosed, Force Ventilated Enclosure(TEFV, IP54, IC-37) Totally Enclosed, Water-to-Air Cooled Enclosure(TEWAC, IP54, ICW-86)Totally Enclosed Air-to-Air Cooled Enclosure(TEAAC, IP54, IC-48) EnclosureNEMAIP CodeIC Code Open Open IP00 IC-01 Drip Proof DP IP12 IC-01 Drip Proof, Fully Guarded DPFGIP22 IC-01 Drip Proof, Guarded DPG IP22 IC-01 Splash Proof SP IP23 IC-01 Weather Protected I WPI IP23 IC-01 Weather Protected II WPII IP24 IC-01 Totally Enclosed, Water to Air Cooled TEWAC IP54 ICW-81 Totally Enclosed, Air to Air Cooled TEAAC...

Open the catalog to page 3

Stator Bracket Frame Stator Insulation is Key > The fabricated steel plate statorframe consists of two or more side plates continuously welded to the wrapper plates and rectangular steel block feet to provide a rigid stator support. The strength of this frame maintains a uniform air gap under all operational stresses. Stator laminations are precision-punched from high-quality low-loss electrical sheet steel which are coated with a thermally stable insulation film (C5 coating) to minimize eddy current losses. The laminations are assem- bled in accurate alignment within the stator frame to...

Open the catalog to page 4

High speed rotors need maximumstrength and stiffness to provide a long life. GE Motors makes its high speed rotor from a solid cylindrical forging and machines out the pole bodies and pole tips. The field wind- ings are edge wound copper strips with dimensionally stable insulation material bonded between the turns. Every turn has mechanically locked and brazed corner joints for maxi- mum strength and every other turn is larger for more efficient cooling. Medium speed machine shafts are manufactured of forged or rolled steel and machined to exact applica- tion specifications. The shaft ends...

Open the catalog to page 5

For grinding mill applications,GE has developed a drive using two, high efficiency, synchronous motor driven pinions on one bull gear. A Quadramatic load sharing drive uses a special winding in addition to the amortisseur winding to dynami- cally alter the rotor flux. These continuous adjustments maintain the load sharing between the two pinions reducing wear and improving performance. This arrangement is generally used across all segments of industry as it requires minimal maintenance and is well suited for hazardous or contami- nated environments. The solid state components utilized are...

Open the catalog to page 6

Cylindrical, two lobe or four lobe sleeve bearingsՕTilting pad bearings Axial thrust bearings - horizontal and vertical Both pedestal and bracket bearingmachines are available based on application requirements. ՕPartial Discharge Sensor KitsAir RTD (Resistance Temperature Detectors)ՕSpace Heaters 50/60 Hz,up to 550 voltsLarge oversized fabricated steel main terminal box - frame mounted or freestanding arrangements are both available.ՕSurge arrestors and/or Surge CapacitorsCurrent and Potential Transformers ՕVibration monitoring equipment Couplings ՕEvery machine is equipped with Resistance...

Open the catalog to page 7

Systems ModelingٕOn-site Research and Development Quadramatic Load Sharing ՕSolid Integral Pole Tip High Speed Rotor Design50 MVA of test capabilities ՕHigh Efficiency Designs Pro-Engineer ՕPower Solutions Team > Experienced application engineers are available to solve your toughest motor or generator systems problems. Call us, we can help! ҕLarge Motors Services Team > Do you have equipment over 20 years old? Do you need more from existing motors? Would you like to know what condition your motors are in? Application Engineering Team > New equipment & installations GE MotorsFort Wayne, IN...

Open the catalog to page 8All GE Motors catalogs and technical brochures

-

Stock Inventory DC Motors

1 Pages

-

MD800 Armored Mill Motor

6 Pages

-

Buyers Guide

174 Pages

-

Oil & Gas

8 Pages

-

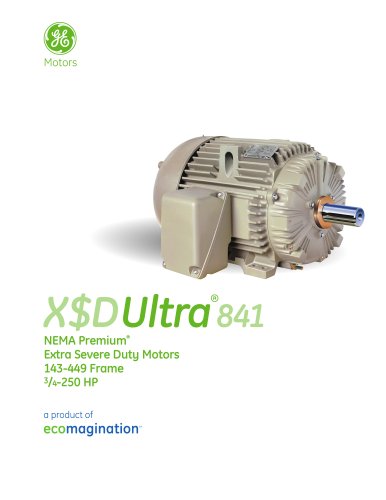

XSD Ultra®

4 Pages

-

Quantum® LMV

4 Pages

-

Mining and Minerals

8 Pages

-

XSD Ultra® 661

4 Pages

-

X$D Ultra® 841

4 Pages

-

X$DUltra® 841 IEC

8 Pages

Archived catalogs

-

MV7000 Flat Pack (FP)

16 Pages

-

Power Conversion

91 Pages

-

LV 7000-6 and 8

2 Pages

-

case study

1 Pages

-

MV7-Series

5 Pages

-

N37

12 Pages

-

D_Harnessing the Power of Wind

20 Pages

-

SVC and STATCOM fact sheet

4 Pages

-

Low Voltage Motors

8 Pages

-

MV6 Medium Voltage Drive

20 Pages

-

LV 7000 Drives

4 Pages

-

Generators Brochure

16 Pages

-

X$D Ultra 841 VSS

6 Pages

-

DC2100e

4 Pages

-

Genuine Parts

6 Pages

-

Synchronous Hydro Generators

10 Pages

-

ProSolar Power Station

3 Pages

-

A new direction for DP

12 Pages

-

Energy $aver

2 Pages

-

X$D Ultra ? 841 VSS

6 Pages

-

MV7000

16 Pages

-

MV4 Series

9 Pages

-

Onduleur Central ProSolar

3 Pages

-

A$DUltra

2 Pages

-

GEA18201A X$D IEC

6 Pages

-

AC and DC Excavator Solution

12 Pages

-

Series 9000-RCM

2 Pages

-

Motors Product Line Brochure

8 Pages

-

2008 Standard Products Catalog

248 Pages

-

GE Motors - Product Line

6 Pages