Catalog excerpts

Dynamic positioning (DP) is a computer-controlled system used to maintain a vessel‘s position and heading by automatically activating propellers and thrusters to counteract the displacing effects of the external environment. Sensors provide information to the control system which incorporates a mathematical model of the vessel including information about the vessel’s dynamics, its machinery and its responses to environmental and other displacing forces. The model information together with the sensor data enables the DP system to calculate the required output for each thruster and propeller...

Open the catalog to page 2

The experience to redefine DP We know DP, deeply. Since the 1970’s we’ve built more than 800 systems, from joystick maneuvering and “simple” DP to multi-redundant DP and Thruster Assisted Mooring Systems (TAMS). Our technological range is coupled with front-line, hands-on expertise in all vessel types. No one is better positioned to develop the DP system you need. By applying our engineering intelligence, and understanding your maritime operations, we’ve evolved DP to the next level. The result: a new range of DP systems developed to deliver the reliability, efficiency and effectiveness you...

Open the catalog to page 3

Unprecedented flexibility for effective maritime operations Putting the Operator in Control GE’s latest range of DP systems is a mariner-focused solution, enhancing situational awareness and rebalancing attention from system management to true seamanship. It delivers the following benefits: • nprecedented flexibility U for effective maritime operations. • n energy-efficient nautical system A to reduce operational costs and emissions. • fully integrated system configured A for optimum power & propulsion performance. GE’s new direction in DP control systems sets new standards of excellence in...

Open the catalog to page 4

Intuitive graphic interface Easy to use – quick to learn for DP operators switching from other DP systems 26-inch touch sensitive multi-touch screen Reduced need for data processing by operator; increased focus on seamanship Configurable displays show data in clear and uncluttered form Easier and faster system navigation Operator/task specific information prioritization Improved focus on positioning the vessel rather than manipulating the control system Screen tilt angle adjustable Enables standing or seated operation Helps reduce screen reflections and glare Screen display available in...

Open the catalog to page 5

An energy-efficient nautical solution GE’s expertise in DP and in power and propulsion systems has prompted the development of DP capabilities which impact on fuel economy, emissions, machinery wear, and machinery maintenance (time/cost). Operational costs are reduced and overall system up time/availability may be increased. Mode Operation Energy Efficient Mode A utomatic position and heading control. Using predictive software to anticipate position variation and to limit thrust changes if the vessel is predicted to remain within the ‘soft’ operating window. the vessel is predicted to move...

Open the catalog to page 6

Simulated drillship example of fuel usage Fuel used in Fuel used in Energy Efficient Fuel used in Energy Efficient "Normal DP" (kg/hr) ; mode - fixed heading (kg/hr) mode - optimum head" (kg/hr] Table 1: Simulated fuel usage at different wind speeds. 3600kW non DP load included Winds eed (m/s) NOx in "Normal DP" NOx in Energy Efficient ! NOx in Energy Efficient mode (kg/hr) mode - fixed head (kg/hr) - optimum head" (kg/hr) Table 2: Simulated NOx emissions at different wind speed. 3600kW non DP load included Table 1 and Table 2 use the probabilities of the different wind speeds to produce a...

Open the catalog to page 7

GE as a full system integrator Positioning DP in the Big Picture At GE, we see the whole ship. That’s because we engineer and supply so much of it, from gas turbines and diesel engines to rotating machines, variable speed drives, drilling systems and automation and control. We power, propel and position the industry. As engineers with broad vision, we understand the role of the DP control system relative to the entire vessel’s operations; its integrated role in a network involving power generation and distribution equipment, propulsion and maneuvering machinery, digital controllers,...

Open the catalog to page 8

Tracking • utotrack – High precision A automatic tracking and heading control along a pre-defined track line using all selected thrusters. • utosail – High speed automatic A tracking and heading control along a pre-defined track using the main propulsion and steering system. R • OV Follow – Automatic tracking and heading control to follow a mobile beacon attached to an underwater vehicle or other object. • hip Follow – Automatic tracking S and heading control to enable the DP vessel to track the relative movement and relative heading of another ship or other mobile structure. • nhanced Ship...

Open the catalog to page 9

And more: A focus on availability We understand the vital importance of vessel availability—and our service focus keeps us actively engaged, both when things are going right, and when they go wrong. Diagnostics and Trending GE’s DP is engineered for high fault tolerance and incorporates: • Self-diagnostic routines • Operator guidance and support to identify and resolve system errors • Standard features such as an inbuilt multi-channel chart recorder and an optional dedicated history station/black box logger Remote Support ViSor Connect is GE’s remote diagnostic and support system based on...

Open the catalog to page 10

By Kind Permission Seacor Marine LLC

Open the catalog to page 11

MAIN OFFICES Australia, Botany Tel: +61 (0) 2 8313 9980 Brazil, Minas Gerais Tel: +55 31 3330 5800 South Africa, Midrand Tel: +2711237 0000 South Korea, Busan Tel: +82 51 710 9015 UK, Rugby (DP Center of Excellence) Tel: +44 1788 563 563 www.gepowerconversion.com Copyright © 2013 General Electric Company and/or its affiliates. All rights reserved. GEA12345 A new direction for DP

Open the catalog to page 12All GE Motors catalogs and technical brochures

-

Stock Inventory DC Motors

1 Pages

-

MD800 Armored Mill Motor

6 Pages

-

Buyers Guide

174 Pages

-

Oil & Gas

8 Pages

-

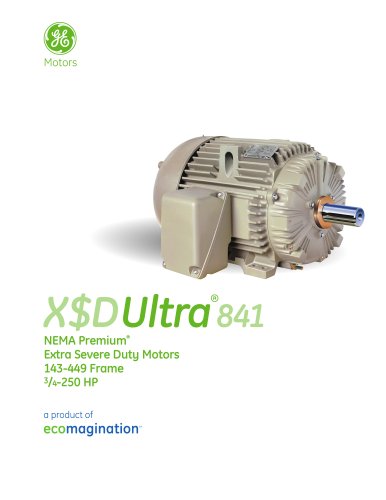

XSD Ultra®

4 Pages

-

Quantum® LMV

4 Pages

-

Mining and Minerals

8 Pages

-

XSD Ultra® 661

4 Pages

-

X$D Ultra® 841

4 Pages

-

X$DUltra® 841 IEC

8 Pages

Archived catalogs

-

MV7000 Flat Pack (FP)

16 Pages

-

Power Conversion

91 Pages

-

LV 7000-6 and 8

2 Pages

-

case study

1 Pages

-

MV7-Series

5 Pages

-

N37

12 Pages

-

D_Harnessing the Power of Wind

20 Pages

-

SVC and STATCOM fact sheet

4 Pages

-

Low Voltage Motors

8 Pages

-

MV6 Medium Voltage Drive

20 Pages

-

LV 7000 Drives

4 Pages

-

Generators Brochure

16 Pages

-

X$D Ultra 841 VSS

6 Pages

-

DC2100e

4 Pages

-

Genuine Parts

6 Pages

-

Synchronous Hydro Generators

10 Pages

-

ProSolar Power Station

3 Pages

-

Energy $aver

2 Pages

-

X$D Ultra ? 841 VSS

6 Pages

-

MV7000

16 Pages

-

MV4 Series

9 Pages

-

Onduleur Central ProSolar

3 Pages

-

A$DUltra

2 Pages

-

GEA18201A X$D IEC

6 Pages

-

AC and DC Excavator Solution

12 Pages

-

Series 9000-RCM

2 Pages

-

Motors Product Line Brochure

8 Pages

-

2008 Standard Products Catalog

248 Pages

-

GE Motors - Product Line

6 Pages