Catalog excerpts

Synchronous Motors

Open the catalog to page 1

Experience Matters We've manufactured motors for over 125 years. In 1879, GE founder, Thomas Edison constructed the first electric motor for a 110 to 120 Volt line at Menlo Park, NJ. This device still exists and is operative! It is located in the Edison Historical Collection in New Jersey. Since 1987, GE has produced over 15,000 medium/high voltage machines. We've been a certified ISO 9001:2000 Quality System since 1992. Six Sigma processes have been hardwired into our manufacturing processes since 1995. And now we presently offer a full range of large motors and These motors are designed...

Open the catalog to page 2

Enclosures Designed for Performance This standard enclosure is suitable for most indoor industrial conditions. Cooling air enters through the end-shields at both ends, passes over the coil end-turns, the rotor and stator, then exits through openings in the sides of the frame. Louvered openings provide protection greater than required by NEMA standards. Air flow is designed carefully to eliminate hot spots and minimize noise. For larger ratings, or for special quieter operating designs, cooling air intake and discharge openings are located in an easily removed "top hat" enclosure. Cooling...

Open the catalog to page 3

Superior Construction Stator Frame And Magnetic Core • Long and Trouble Free Life Designed to provide opti- inspection. The heavy duty fabricated steel or cast-iron maintain alignment. Stator laminations are precision punched from high quality, low loss electrical sheet steel and coated with a thermally stable insulat- ing film. Most ratings are of rectangular frame construction, uti- lizing packaged cores. The magnetic core consists of laminations highly compressed for mechanical strength and completely wound before the core package is inserted into the frame. This construction permits...

Open the catalog to page 4

Rotors Squirrel Cage Rotor • • • • • Lower Rotor Inertia Greater Stall Time Strong Bar to End-Ring Joints Reduced Windage Noise Optimum Torque vs. Slip Design The squirrel cage induction motor is basically a rugged yet simple arrangement of shaft, magnetic circuit and electric winding. The magnetic circuit consists of discs punched from electrical grade thin sheet steel assembled to form a laminated magnetic core mounted on the shaft. The laminations are coated with a thermally stable insulating film to reduce magnetic losses and yet maintain dimensional stability in the face of the severe...

Open the catalog to page 5

Synchronous Rotor • Starting Winding Versatility • Brushless Excitation for Minimum Maintenance and Maximum Reliability Synchronous rotors are designed primarily for applications requiring highly efficient motors. Each pole assembly is made from high strength steel laminations with a DC field winding encircling the pole body. The field winding consists of a rectangular section of insulated copper wire wound directly on an insulated pole body and bonded by a high temperature, high strength insulating epoxy resin which, when cured, results in a coil impervious to dirt, moisture and other...

Open the catalog to page 6

Balancing After assembly, all rotors are dynamically balanced to the API 541 balancing grade to achieve quiet running and long bearing life. API 541 balancing grade is less than one-third of the ISO 2.5 balancing grade usually adopted by the industry. Step balancing techniques according to API 541 are applied to all 4-pole spider shaft designs and all 2-pole machines. All 2-pole flexible rotor designs have a central rotor balancing plane according API 541. The balancing machines are capable of balancing even the largest rotors prior to assembly. The completed motor is run at no-load rated...

Open the catalog to page 7

Vibration Equipment Seismic-type such as Robertshaw™ measures overall vibration. 1-6 units are located on the frame. Proximity-type such as Bentley Nevada™ measures the shaft vibration. 2-5 units are located on the bearing housing. Acceleration-type such as Metrix™ measures bearing housing vibration. 1-6 units are located on the bearing housing. Other Accessories Whenever required, the following accessories may be supplied: • Surge protection • Tachometers (capacitors and lightning arresters) • Overspeed switches • Current transformers • Slide rails • Pressure switch • Sole-plates • Space...

Open the catalog to page 8All GE Motors catalogs and technical brochures

-

Stock Inventory DC Motors

1 Pages

-

MD800 Armored Mill Motor

6 Pages

-

Buyers Guide

174 Pages

-

Oil & Gas

8 Pages

-

XSD Ultra®

4 Pages

-

Quantum® LMV

4 Pages

-

Mining and Minerals

8 Pages

-

XSD Ultra® 661

4 Pages

-

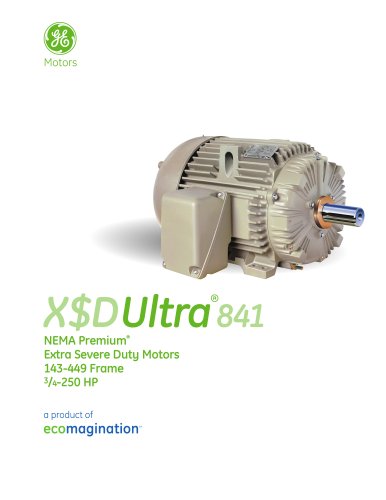

X$D Ultra® 841

4 Pages

-

X$DUltra® 841 IEC

8 Pages

Archived catalogs

-

MV7000 Flat Pack (FP)

16 Pages

-

Power Conversion

91 Pages

-

LV 7000-6 and 8

2 Pages

-

case study

1 Pages

-

MV7-Series

5 Pages

-

N37

12 Pages

-

D_Harnessing the Power of Wind

20 Pages

-

SVC and STATCOM fact sheet

4 Pages

-

Low Voltage Motors

8 Pages

-

MV6 Medium Voltage Drive

20 Pages

-

LV 7000 Drives

4 Pages

-

Generators Brochure

16 Pages

-

X$D Ultra 841 VSS

6 Pages

-

DC2100e

4 Pages

-

Genuine Parts

6 Pages

-

Synchronous Hydro Generators

10 Pages

-

ProSolar Power Station

3 Pages

-

A new direction for DP

12 Pages

-

Energy $aver

2 Pages

-

X$D Ultra ? 841 VSS

6 Pages

-

MV7000

16 Pages

-

MV4 Series

9 Pages

-

Onduleur Central ProSolar

3 Pages

-

A$DUltra

2 Pages

-

GEA18201A X$D IEC

6 Pages

-

AC and DC Excavator Solution

12 Pages

-

Series 9000-RCM

2 Pages

-

Motors Product Line Brochure

8 Pages

-

2008 Standard Products Catalog

248 Pages

-

GE Motors - Product Line

6 Pages