Catalog excerpts

GE has been setting the standard in generator manufacturing for over 130 years.

Open the catalog to page 2

GE created and implemented the first fundamentals of large-scale electrical generation. Today we continue to deliver innovative power generation solutions to the world. We continue to innovate with product quality Generators are designed and manufactured to operate efficiently and reliably in challenging applications and severe environments where ease of maintenance is critical. Standards and Certifications We‘ve designed rotating machines that comply with global standards and certifications, including but not limited to IEC, NEMA, API, CSA, Lloyds, DNV, ABS, ATEX, IEC ExN, and ExP. Zone 1 or 2...

Open the catalog to page 3

Generator Products 4-Pole Synchronous Gas and Steam Turbine Applications Our range of 4-pole generators provide a reliable product which is based on a modular construction concept utilizing the latest design and manufacturing techniques. All generators include Vacuum Pressure Impregnation (VPI) insulation systems (for both the stator and rotor components) and a unique vent stator technology for maximum heat dissipation. Stators are either mounted in a box-frame with end-shield mounted bearings or in a base frame with pedestal bearings. Up to 20 MW a laminated rotor is used. Above 20 MW...

Open the catalog to page 4

4-Pole Synchronous Gas and Steam Turbine Generator Beta Diesel and Gas Turbine Generators

Open the catalog to page 5

Generator Products Reciprocating Engine Driven (Delta) Diesel and Gas Reciprocating Engine Applications Wind Turbine Applications This design has the stator mounted into a base-frame with pedestal bearings to support the rotor. These are used in many applications from Prime and Emergency Power to Marine Power. Although these machines employ the same insulation systems as other generators, they tend to be more specifically designed for the application or project. The speed can range from 17 to 1800 RPM depending on the generator type required. The speed range for these machines is very wide....

Open the catalog to page 6

Delta Diesel and Gas Turbine Generator Wind Turbine Generator

Open the catalog to page 7

Rotors Laminated Pole Laminated cruciform assembly Wire-on-Edge field windings Coils wound directly on poles Cooling vee-block designs Advanced ventilation and fan designs This rotor has a laminated cruciform assembly and a wire-on-edge field winding. Each pole face has a set of damper bars brazed to a copper segment at each end, and coil support bars to prevent the ends of the coils from moving in service. After winding and vacuum pressure impregnation treatment, the rotor assembly is shrunk on to the shaft to ensure a positive fit. The heating process is computer controlled with a number of...

Open the catalog to page 8

Rotors Integral Tip Solid Pole The pole tips or shoes on this rotor are machined from the single rotor forging. All other features are the same as the bolted tip rotor. Solid poles hold a strip-on-edge field winding. These types of rotors are used in special 60 Hz applications or otherwise specified by customers requiring maximum durability. Cylindrical Wound This rotor is used in applications where a distributed winding is required. The rotor body is made from laminations with slots to take the windings. The windings are placed into slot-liners when inserted and wedged in at the surface,...

Open the catalog to page 9

Stators Two Layer Lap Winding Low-loss lamination grade No core-pack welding Individual slot wedging Thermal vent technology Global VPI with rotate cure The stator core assembly consists of varnished laminations of cold-rolled low-loss silicon steel, clamped between compression plates. The laminations are supplied in the finally annealed condition, and are insulated to reduce eddy current losses. The core is built around a central mandrel, to enhance the bore profile. There are radial ventilation ducts at intervals along the core length, formed by spacers welded to laminations, with similar...

Open the catalog to page 10

Vacuum Pressure Impregnation (VPI) Void free insulation is vital for the life of medium and high voltage insulation systems. The stator is heated in an oven to dry out any moisture. Then it is placed into a pressure vessel where the lid is vacuum sealed. Then resin, at varying temperature, is pumped into the chamber to fill all voids on the stator. After a period of time, dry air is pumped into the top of the vessel creating a “pressure blanket” over the resin, “pushing” it into all remaining voids. The pressure is then released and the stator is placed in an oven for the resin to cure. The...

Open the catalog to page 11

Typical Enclosures Open Vented Enclosure ODP, WPI, WPII IP00-44, ICOA1 Duct Ventilated Enclosure

Open the catalog to page 12

Analysis Tools Finite Element Modern analysis tools such as finite elements make predictions regarding performance more accurate. Before integrating the generator with an engine, we calculate all the natural frequencies of the machine in order to avoid exciting them. Through a particularly advanced mathematical simulation we can calculate the effects of an explosion in a terminal box due to an electrical fault. This allows us to optimize the integrity of the terminal box during a very rare fault condition. Fluid Dynamics We analyze our generator designs to improve their ability to not run...

Open the catalog to page 13

Training & Service Generator Controls Global Service Capability The GEPC RVD Mk III system uses a Programmable Logic Controller (PLC) to perform all the control functions and fire a power stack for the excitation. These are generally part of a “turnkey” type system where many other controls functions are being supplied by GE. These systems are most common in large, utility-type generators. GE’s full global service network delivers fast initial response and follow-up on all warranty and service issues including: Controls Training GE can supply comprehensive training in controlling generators...

Open the catalog to page 14

Global Expertise Rotating Machine Factories Converter Factories Business Centers Complete Product Offering Proven Experience Few manufacturers can claim the depth and breadth of experience that GE has in building and delivering electrical and mechanical solutions for customers. GE offers a complete portfolio of rotating machines. Innovative Technology World-Class Service GE has the global resources and capabilities to enhance the performance and reliability of your machines. s n GE is constantly innovating product technologies to meet and exceed customer expectations.

Open the catalog to page 15All GE Motors catalogs and technical brochures

-

Stock Inventory DC Motors

1 Pages

-

MD800 Armored Mill Motor

6 Pages

-

Buyers Guide

174 Pages

-

Oil & Gas

8 Pages

-

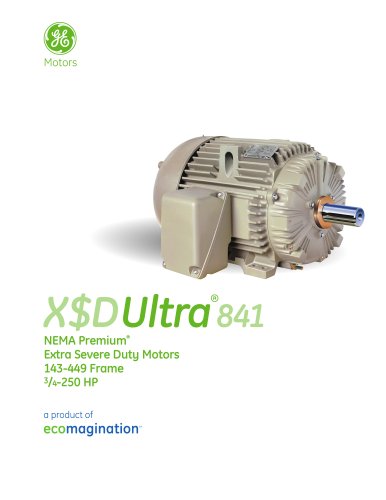

XSD Ultra®

4 Pages

-

Quantum® LMV

4 Pages

-

Mining and Minerals

8 Pages

-

XSD Ultra® 661

4 Pages

-

X$D Ultra® 841

4 Pages

-

X$DUltra® 841 IEC

8 Pages

Archived catalogs

-

MV7000 Flat Pack (FP)

16 Pages

-

Power Conversion

91 Pages

-

LV 7000-6 and 8

2 Pages

-

case study

1 Pages

-

MV7-Series

5 Pages

-

N37

12 Pages

-

D_Harnessing the Power of Wind

20 Pages

-

SVC and STATCOM fact sheet

4 Pages

-

Low Voltage Motors

8 Pages

-

MV6 Medium Voltage Drive

20 Pages

-

LV 7000 Drives

4 Pages

-

X$D Ultra 841 VSS

6 Pages

-

DC2100e

4 Pages

-

Genuine Parts

6 Pages

-

Synchronous Hydro Generators

10 Pages

-

ProSolar Power Station

3 Pages

-

A new direction for DP

12 Pages

-

Energy $aver

2 Pages

-

X$D Ultra ? 841 VSS

6 Pages

-

MV7000

16 Pages

-

MV4 Series

9 Pages

-

Onduleur Central ProSolar

3 Pages

-

A$DUltra

2 Pages

-

GEA18201A X$D IEC

6 Pages

-

AC and DC Excavator Solution

12 Pages

-

Series 9000-RCM

2 Pages

-

Motors Product Line Brochure

8 Pages

-

2008 Standard Products Catalog

248 Pages

-

GE Motors - Product Line

6 Pages