Catalog excerpts

Masoneilan* High Capacity Control Ball Valve Instruction Manual GE Data Classification : Public

Open the catalog to page 1

b | GEOil&Gas © 2014 General Electric Company. All rights reserved.

Open the catalog to page 2

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECT-SPECIFIC REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL OPERATION AND MAINTENANCE PROCEDURES. SINCE OPERATION AND MAINTENANCE PHILOSOPHIES VARY, GE (GENERAL ELECTRIC COMPANY AND ITS SUBSIDIARIES AND AFFILIATES) DOES NOT ATTEMPT TO DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND REQUIREMENTS CREATED BY THE TYPE OF EQUIPMENT PROVIDED. THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL UNDERSTANDING OF THE REQUIREMENTS FOR SAFE OPERATION OF MECHANICAL AND ELECTRICAL...

Open the catalog to page 3

Contents Important : Safety Warning1 1.0 Introduction Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2.0 Installation 2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2.2 Pipeline Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Open the catalog to page 4

WARNING Safety Information Important - Please Read Before Installation Masoneilan 36005 Series instructions contain DANGER, WARNING, and CAUTION labels, where necessary, to alert you to safety related or other important information. Read the instructions carefully before installing and maintaining your control valve. DANGER and WARNING hazards are related to personal injury. CAUTION hazards involve equipment or property damage. Operation of damaged equipment can, under certain operational conditions, result in degraded process system performance that can lead to injury or death. Total...

Open the catalog to page 5

1.0 Introduction The following instructions are designed to assist maintenance personnel in performing most of the maintenance required on the 36005 V-Max* valve and if followed carefully will reduce maintenance time. GE Masoneilan has highly skilled Service Engineers available for start-up, maintenance and repair of our valves and component parts. In addition, regularly scheduled training programs are conducted to train customer service and instrumentation personnel in the operation, maintenance and application of our control valves and instruments. Arrangements for these services can be...

Open the catalog to page 6

V-Max Valves Actuator Model 33, Size AC Actuator Position in Relation to Valve Body Numbering System: 1 to 8 Actuator Model 33, Sizes B and C © 2014 General Electric Company. All rights reserved. Masoneilan 36005 Series High Capacity Control Ball Valves | 3

Open the catalog to page 7

2.1.1 Unpack valve carefully to avoid damage to valve, accessories, or tubing. 2.1.2 Record all valve and accessory serial plate data for future reference. Always provide serial and model numbers when ordering spare parts. CAUTION Do not remove button head screw (9) and washer (10) during installation. The function of these parts is to hold the retainer (3) and seal ring (8) in place and should be removed only when the valve is to be disassembled for maintenance (Figure 2). A. Before installing the valve in the line, clean pipe and valve of all foreign materials such as welding chips,...

Open the catalog to page 8

CAUTION CAUTION Before proceeding determine valve action (air to open/air to close), refer to the appropriate figure (Figure 10 to open, Figure 11 to close). To obtain proper alignment, the lever must be oriented on the shaft so that the slot in the end of the shaft and arrows or indicator lines are aligned as shown; with the ball in the closed position, the distance between the top of the bracket and the top of the pivot pin must be as shown. G. lide lever (32) and lever arm (64) back onto shaft in S desired position. Slide indicator arm (35) back onto shaft. Align bracket and slide back...

Open the catalog to page 9

CAUTION removal of the bracket is not required. CAUTION Before proceeding determine valve action (air to open/air to close). G. lide lever (32) back onto shaft in desired position. S Slide indicator arm (35) back onto shaft. Align bracket and slide back onto mounting studs (26) and packing flange studs (25). Replace mounting stud nuts (24) and washers (18). Slide packing flange (23) back onto packing flange studs (25) and replace packing flange stud nuts (24). H. Remount actuator onto housing and replace actuator mounting hex nuts (75) and washers (76). Position lever (32) so that rod end...

Open the catalog to page 10

figure (Figure 10 to open, Figure 11 to close). To obtain proper alignment, the lever must be oriented on the shaft so that the slot in the end of the shaft and arrows or indicator lines are aligned as shown; with the ball in the closed position, the distance between the top of the bracket and the top of the pivot pin must be as shown. F. lip lever (32) and lever arm (64) and replace on shaft F 90 away from original position. Replace indicator arm (35). Slide bracket back onto bracket mounting studs (26), replace washers (18) and nuts (24) and tighten. Slide packing flange (23) back over...

Open the catalog to page 11

CAUTION adjustment as noted in step I above. Return ball plug (2) to open position. CAUTION Do not exceed maximum air supply pressure. Keep hands clear of actuator stem and linkage. Loosen rod end bearing locknut (93) and adjust rod end bearing (94) so that holes in lever (32) and rod end bearing (94) line up. Insert pivot pin (39) and replace retaining rings (40). I. For both air to open and air to close action, stroke valve fully to ensure proper closure of ball plug and operation of valve. It may be necessary to readjust rod end bearing slightly by loosening locknut and rotating stem....

Open the catalog to page 12

replace clevis pin (66), retaining clips (63), and pivot pins (72). H. et and lock indicator arm (35) to indicate plug position. S I. heck that handwheel operates valve through full range C of travel. There is a 1/2" adjustment available at the end of the handwheel extension. Retract handwheel, remove end cap (51) and cap screw (55B). Rearrange stop (55A) and/or spacer (55C) to obtain desired extension. 3.2 Bracket Subassembly – Model 33, size AC only. Refer to section 3.1 for sizes B & C 3.2.1 Disassembly CAUTION When disconnecting actuator rod end bearing from shaft arm, the ball is...

Open the catalog to page 13All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

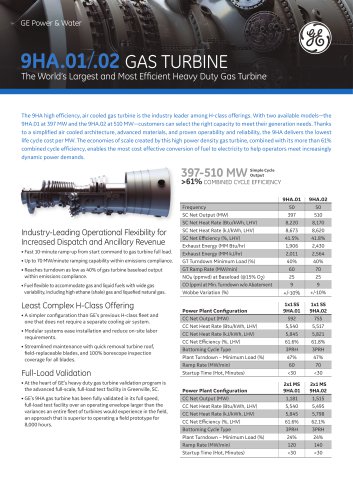

9HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages