Catalog excerpts

The impact of new regulations Increasingly stringent emissions standards play a more prominent role in purchasing strategies for new engines. Ideally, anyone buying equipment today should think about regulatory compliance considerations as well as asset life, technological fit and mobility requirements. An effective buying strategy factors in the true cost of meeting current and future compliance standards as well as anticipating yet unknown standards. As new rounds of emissions regulations go into effect, the Environmental Protection Agency's (EPA) new emissions standards for nitrogen oxides (NOx), carbon monoxide (CO), volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) have challenged the natural gas industry to reduce levels of these substances during operation. Although new greenhouse gas (GHG) regulation isn't currently planned, the EPA intends to propose a revised ozone standard which could be implemented as early as 2014. This will indirectly affect regulation of NOx and VOC. Keep in mind EMISSIONS REGULATIONS • Mandated NOx levels are trending lower, reaching 0.5 g/BHP-hr and below. • The EPA intends to propose a revised ozone standard which could be implemented as early as 2014. • These restrictive emissions standards on NOx force lean-burn engines to increase the amount of air in the air/fuel ratio, which can deteriorate the quality of the combustion. GE Power & Water Gas Engines COST EFFICIENCY • Rich-burn engines operate with a wide margin for both knock and misfire, allowing a high tolerance for fuel composition • As NOx approaches 0.5 g/BHP-hr and below, rich-burn engines can operate more cost effectively than lean-burn engines. CARBON FOOTPRINT & HAPS • Methane is a significant greenhouse gas and rich-burn engines emit much less methane than lean-burn engines. • Using SCR technology, with urea as a reductant, to further lower NOx emissions from lean-burn engines can increase the carbon footprint. • Of all the Hazardous Air Pollutants, formaldehyde is one that should be addressed and minimized as much as possible. • Because lean-burn engines operate at lower combustion temperatures, up to 10 times more formaldehyde can be Much less of a percentage of NOx than lean burn. Current EPA Regulations were implemented in 2010 State requirements may exceed federal regulations Although current federal regulations are as shown above, some states will enact even more stringent requirements. For example, states that currently have severe non-attainment status have begun mandating NOx levels of 0.5 g/ BHP-hr and even lower. Companies with large fleets are particularly impacted, where mobility is critical, as is application flexibility. When you're talking larger horsepower applications, lean-burn engines offer good power density. Fuel efficiency has traditionally been an advantage for lean-burn engines. However, as emissions standards continue to mandate lower NOx levels, fuel consumption can increase in lean-burn engines. At NOx levels near 0.5 g/BHP-hr, the fuel consumption difference between lean-burn and rich-burn combustion types can become negligible. Get long-term results with GE's Waukesha gas engines We understand that engine purchases represent a considerable investment—one that you must weigh carefully. We welcome the opportunity to help plan for your future. For additional information, email marketing.department@ge.com or contact plan ahead. stay ahead. your Waukesha gas engines representative. GE Power & Water 1101 West St. Paul Avenue Waukesha, WI 53188-4999 P: 1.262.547.3311 F: 1.262.549.2759 How regulations, efficiency and carbon footprint affect engine choice. imagination at work 1278 11/12 GEA-19177

Open the catalog to page 1

Evaluating rich-burn and lean-burn engines GE’s Waukesha* gas engines are designed to perform reliably in isolated, mission-critical and demanding applications. Featuring durable design and greater efficiency In the course of working toward lower emissions, efficiency can be affected. More and more, achieving higher efficiency while reducing emissions is a key objective. carbon footprint Measuring the environmental impact of an installation involves many variables, with some factors playing a bigger role than others. Rich-burn engines use a Three-Way Catalyst (TWC), also known as Non-Selective...

Open the catalog to page 2All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

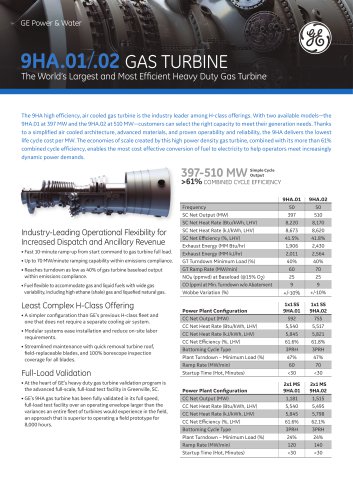

9HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages