Catalog excerpts

Fuel Gas System A typical gas fuel configuration employs shutoff valves for safety reasons and metering valves to control the machine load and CO/NOx emissions. Depending on the level of DLN performance requested, two or three metering valves are needed in order to control gas injection in the various parts of the combustion chamber. operation of the unit is supplied, including: • Unit control panel (on GT skid) • Motor control center (on GT skid) • VFD for gas turbine starting • Generator control and protection panel • DC panel & battery charger Unit Control Panel The GE10 control system is standardized to assure a high degree of integration between the turbine and the generator. The system is based on the GE Fanuc RX3i PAC System platform with remote I/O modules. The Bently Nevada 1701 is installed for the acquisition of data from seismic probes and for humming detection. The control, monitoring and tuning of unit parameters can be performed remotely. Remote data acquisition does not interfere with normal site operations. Control CAB An integrated control cab containing all electrical panels for control and • Batteries • On site monitoring system The cab is provided with an air conditioning system, normal and emergency lighting, a smoke detection system and manual fire suppression bottles. Air Filter The air filtration system consists of a self-clearing vertical cartridges filter house, an inlet duct and a silencer. This system also provides an anti-icing function without any additional hardware. Filter inspection and replacement of filter cartridges are facilitated by gangways and ladders that are included as part of the scope of supply. Package Arrangement The gas turbine enclosure consists of a separate structure and panels mounted on a base plate. Access doors are included for normal maintenance operations and inspections. The ventilation system for internal cooling of the package consists of two 100% axial fans. The enclosure includes fire & gas detection systems and an automatic CO2 -type fire fighting system. The enclosure guarantees a sound pressure level lower than 85 dBA at 1 m. An 80 dBA version is available upon request. The GE10-1 package is designed specifically for power generation applications and is optimized to minimize plant dimensions and to reduce maintenance cost and time. The single lift architecture minimizes the site installation and commissioning lead time. The integrated control cab eliminates civil works for the control room and site wiring activities. Available Options • Dual Fuel DLN version (liquid + gas fuel) • 6.0 kV Electric Generator • 80 dBA sound pressure level package • Indoor version • H2O oil cooler • STD exhaust duct (12 m) • Lubrication stand-by pump • Control cabinet located alongside the unit • Additional Pre-Engineered BN1701 for complete vibration monitoring

Open the catalog to page 1

Nuovo Pignone S.p.A. via F. Matteucci, 2 50127 Florence - Italy T +39 055 423211 F +39 055 4232800 www.ge.com/oilandgas GE imagination at work COMK/MARK 839/II - Designed by: Studio Tre Fasi Printed by: Sagraf - 11-2006 ©2006 Nuovo Pignone S.p.A. all rights reserved

Open the catalog to page 2

Axial Compressor The compressor is a high Performance, eleven-stage axial flow design with a 15.5:1 pressure ratio derived from GE Aircraft Engine transonic flow aero design technology. The rotational speed is 11000 rpm with a mass flow of 47 kg/s. The antisurge margin exceeds 25%. Advanced 3D airfoils are used for vanes and blades, and the first three rows of stator blades are adjustable to optimize operability. Being a cold-end drive configuration guarantees reduced flange movement during gas turbine thermal transients. A patented GECC-1 aluminum ceramic coating is provided for...

Open the catalog to page 4

The GE10 is a heavy-duty gas turbine in the 12MW range, available in either a single or a two-shaft configuration. It is the evolution of the field proven PGT10 and incorporates the latest in aerodynamic design, and compact and versatile package arrangements. The GE10 engine design has been highly refined based on the extensive experience gained operating in all types of environments. There are over two hundred PGT10A/GE10 units running under conditions ranging from the cold of Alaska and Siberia to the heat of the desert and the humidity of the tropics. Its efficiency and operational...

Open the catalog to page 5

Engine Characteristics The well proven GE10-1 gas turbine is a heavy duty single shaft engine that has accumulated a large number of fired hours, and has leveraged the experience of the previous PGT10. The cases are horizontally split and the rotor has a disk architecture. The combustion system consists of a horizontally positioned single can. The GE10-1 is available in both Diffusion Combustion System and DLN (Dry Low NOx) versions (15/25 ppmvd NOx) and is able to burn a wide range of liquid and gas fuels, including Low BTU gas and hydrogen.

Open the catalog to page 6

GE10-1 Gas Turbine SPECIFICATIONS Axial Compressor • 11-Stage Axial Flow • 15.5:1 Pressure Ratio Combustion Chamber • Single Can Combustor • Pollution prevention: DLN Gas Fuel at 25 ppmvd NOx DLN Gas Fuel at 15 ppmvd NOx DLN Dual Fuel Gas Fuel at 25 ppmvd NOx DLN Dual Fuel Liquid Fuel at 85 ppmvd NOx Turbine GE10-1 Nominal Rating - ISO • 3-Stage HP Turbine 11000 rpm At 15 °C, Sea Level, No External Pressure Losses, Relative Humidity 60%, Natural Gas Fuel with LHV = 32 to 44 MJ/Nm3 GE10-1 ELECTRICAL OUTPUT (kW) ELECTRICAL EFFICIENCY (%) EXHAUST FLOW (kg/sec) EXHAUST TEMPERATURE (°C) GE10-1...

Open the catalog to page 7

Maintainability GE10 maintenance can be carried out either “on-site” or at an authorized shop. An engine exchange maintenance approach can be adopted to maximize the unit availability. Enclosure doors, and flexible piping and electrical connectors permit the engine to be easily removed, and a back-up engine quickly installed to minimize the plant down time. The engine is provided with borescope holes for periodic inspection of the internals, and the combustion chamber can be disassembled without removal of any of the engine casings. GE gives the highest priority to engineering and field...

Open the catalog to page 8All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

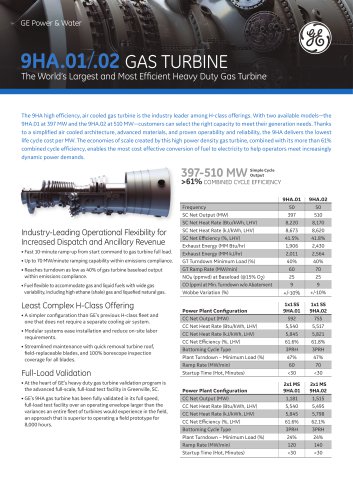

9HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages