Catalog excerpts

fact sheet Fabric Filter Bags & Cages GE Energy delivers reliable and durable fabric filter bags and cages engineered to meet the needs of your unique system. GE Energy can deliver most any type of filter bag for your baghouse, regardless of OEM design and system conditions. The charts below specify the most popular styles, fabrics, and finishes, and the conditions they are most suited to handle. Other fabrics are available by request. Max. Continuous Operating Temperature Energy Absorbsion Filtration Properties Moist Heat Good Excellent Good Excellent Excellent Poor Excellent Good Excellent Good Excellent Good Fair Excellent Fair Excellent Alkalines Mineral Acids Oxygen (15%+) Excellent Excellent Excellent Fair Good Excellent Fair Fair Excellent Excellent Excellent Poor Good Fair Excellent Fair Good Excellent Fair Poor** Excellent Excellent Excellent Excellent *Sensitive bag-to-cage fit, ** Fair with chemical or acid resistant finishes, *** Must oversize bag for shrinkage for temperatures above 450°F (232°C). For capture of fine particulate, improved filtration efficiency, cake release, and airflow capacity Polyester, Aramid, Acrylic, Polypropylene (felt and woven), P84, PPS, Teflon/PTFE Recommended for improved cake release Polyester, Polypropylene, Acrylic, Aramid, PPS, P84 (felts) Provide short-term improvements for cake release (may impede airflow) Polyester, Polypropylene (felts) Aids initial dustcake development and provides limited water repellency Retards combustibility (not flame-proof) Improved filtration efficiency and cake release (may impede airflow in certain applications) Polyester (felt and woven) Flame Retardant Acrylic Coatings (Latex Base) Polyester, Polyproylene (felt and woven) Polyester and Acrylic felts Improved water and oil repellency: limited cake release Polyester, Aramid (felt), PPS Finish Purpose BHA-TEX® ePTFE Membrane For capture of fine particulate, improved filtration efficiency, cake release, and airflow capacity Cement/lime kilns, incinerators, coal-fired boilers, cupola, ferro silica/alloy, furnace Silicone, Graphite, Teflon® Protects glass yarns from abrasion, adds lubricity For non-acid conditions, primarily for cement and metal foundry applications Penetrating Finishes GE Energy can design any type of filter bag or element to enhance the performance of your dust collector. Finish Purpose BHA-TEX® ePTFE Membrane Acid Resistant Helps shield glass yarn from acid attack to Coal-fired boilers, carbon black, incinerators, extend life cement, industrial, and boiler applications Provides enhanced fiber to fiber resistance Industrial and utility base load boilers under to abrasion and limited chemical resistance mild pH conditions, cement and lime kilns Provides improved acid resistance and reduces fiber to fiber abrasion, resistant to alkaline attack, improved fiber encapsulation Coal-fired boilers (high and low sulfur) for peak load utilities, fluidized bed boilers, carbon black, incinerators

Open the catalog to page 1

fact sheet Properly engineered cages help protect your filter investment. Omni Cage The Omni cage top was developed to facilitate snap- A well-built cage is critical to the overall performance and band bag removal. It has a detachable top which durability of your filter bag. GE Energy cages feature evenly allows removal of the cage top first. With the cage spaced rings and wires, with a rounded bottom pan (never top no longer blocking access to the snap-band, the band can be snapped loose from the tubesheet, and cringed) to help ensure proper filter fit. Choose from a number of materials to...

Open the catalog to page 2All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

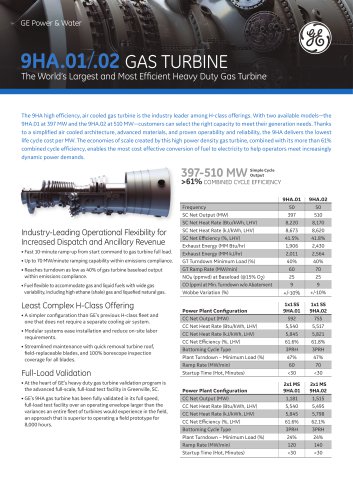

9HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages