Catalog excerpts

Dresser* Turbine Meters Above all - accuracy and reliability

Open the catalog to page 1

GE Oil & Gas’ innovative Dresser Turbine Meter helps reduce installation and maintenance costs while improving measurement accuracy Built with Operation in Mind Design Features Designed to measure gas velocity, the operating principle of the turbine meter incorporates an innovative method of conditioning flow in the meter body. A straightening section in the meter body conditions the gas flow by removing undesired swirl, and turbulence before it reaches the turbine rotor. The dynamic forces from gas flow initiate rotation of the turbine rotor. The precision machined rotor, mounted on an...

Open the catalog to page 2

This feature offers modular flexibility in terms of minimum and maximum capacity. In accordance with European Standard EN 12261, 6.4 Removable meter mechanism, 6.4.1 Integrity, 6.4.1.1 Requirements that states “the design and integrity of a meter with removable mechanism or cartridge shall not be affected by the removal or replacement of the measuring element or cartridge. A meter will be deemed to meet this requirement if it remains leak tight, as defined in 6.2.3, when subjected to the test given in 6.4.2”. For example, the 6” turbine meter body may be ordered with a Qmax of 650 m3/h,...

Open the catalog to page 3

Effective removal of dirt and dust along with oil refreshment enhances turbine meter accuracy. This is important in applications where gas quality is inferior. Some gas networks have locations where flowing gas includes increased levels of dirt, entrapped liquids and other foreign materials. For applications with inferior gas quality, conventional oil injection systems only add oil to bearings and other critical gears. Flushing dirty oil can significantly improve bearing and gear performance. The Dresser Turbine Meters incorporate an inventive oil refreshing and flushing lubrication system....

Open the catalog to page 4

Turbine Meter Advantages ■ Precision machined rotor, superior component parts, and robust body design provides long-term accuracy and reliability. Replaceable Measurement Cartridge (RMC) allows customers to design small metering stations when planning for future meter capacity increases. Low cost associated with government accuracy test directives by replacing the existing measurement cartridge with a new pre-calibrated cartridge. Reduce the need to replace the entire meter by replacing a measurement cartridge when it is necessary to perform important repair work. Multi-stage flow...

Open the catalog to page 5

Calibration Dresser Turbine Meters and removable cartridge assemblies are each supplied with a calibration certificate. The initial verification and calibration are carried out at the factory on an NMi and/or PTB approved calibration bench. All Dresser Turbine Meters are designed for outdoor installation. The index is IP65/IP55 approved. Gas pipes must be clean and free from foreign impurities such as sand, dirt, welding debris and other particles, as well as liquid. Where dirty gas exists, it is recommended to fit the meter with an automatic lubrication system and or a purge system. Note:...

Open the catalog to page 6

Size DN Meter Data Temperature Range -25 to 55° C Aluminum Body (other temperatures on request) -10 to 55° C Steel Body -25 to 55° C Cartridge Environmental Temperature -25 to 55 °C (other temperatures on request) Pressure Loss Flange/Pressure Ratings PN 10, 16 / ANSI 150, 300, 600 (other Flange Rating on request) Depending on Flange/Pressure Rating (on request) Refer to Price List Consult Factory 2 Each HF Turbine Wheel Consult Factory

Open the catalog to page 7

GE Oil & Gas 16240 Port Northwest Dr., Suite 100 Houston, TX 77041 P: 832.590.2303 F: 832.590.2494 7051HS Vasserveld The Netherlands P: +31 (0) 31527 1100 F: +31 (0) 31527 1105 Visit us online at: www.ge.com/energy 2011 General Electric Company All Rights Reserved *Denotes trademark of General Electric Company

Open the catalog to page 8All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

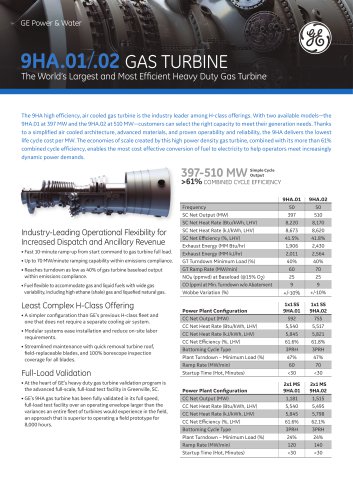

9HA.01 / .02 GAS TURBINE

2 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages