Catalog excerpts

Consolidated* 1900/P Series Safety Relief Valve Overview The Consolidated 1900/P series safety relief valve from GE is designed to easily adapt to a wide variety of application requirements. Features & Benefits • Low cost of ownership. Heavy duty construction provides longer valve service life, reduced maintenance costs, and easy valve conversions. • Simplified conversion. Design flexibility and parts interchangeability accommodate process changes by simplifying conversion to a variety of designs. • Improved leak protection and safety. A soft seat design feature helps keep the valve leak free at 95 percent of set pressure over 100 psig., while a backup metal seat provides additional safety. • Enhanced seat tightness: The patented Thermodisc* Seat (standard on the 1900/P1 and 1900/P3 series valves) delivers enhanced seat tightness. • Compliance to API Standard 526-2002. These valves comply with API Standard 526 Fifth edition, 2002. When required for replacement , Consolidated 1900/P series valves are also available with connections and dimensions in accordance with supplanted API Standard Third edition 1984 and prior editions. fact sheet

Open the catalog to page 1

fact sheet 1900/P Scope of Design The Consolidated 1900/P series safety relief valves are designed for ASME B and PVC, Section I steam and flashing water applications and organic vapor service applications only. Standard in all three types, the Thermodisc* Seat feature of these valves provides a high degree of seat tightness for steam service or organic fluid applications. INLET SIZES inch (25.4 mm) through 1 8 inch (203.2 mm) Note: The 1900/P1 and 1900/P3 series designs are not intended for ASME B and PVC, Section I boiler drum, superheater or reheater applications. 1900/P1 Series...

Open the catalog to page 2All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

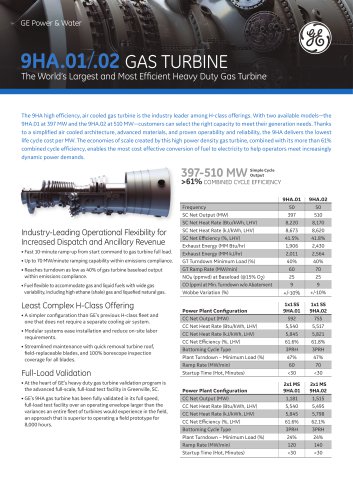

9HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages