Catalog excerpts

Consolidated* 1811 Series Safety Valve Overview The Consolidated Type 1811 safety valve from GE is a cost-effective, high- capacity, flanged steel safety valve designed for steam service. Features and Benefits • variety of pressure/temperature classes, orifice sizes and inlet/ A outlet combinations provide a flexible selection of safety valves to meet industrial needs at the lowest cost. • ow spindle bearing point and concentric spindle loading L virtually eliminate the natural tendency for the disc to assume a horizontal position during the opening and closing cycle of the valve. • he mechanical flexibility of the Thermodisc* allows the system T pressure to assist in sealing the contact surface between the valve seat and Thermodisc.. • eal welding the seat bushing into the base assures no leakage of S steam past the threaded area of the seat bushing. • ual ring adjustments allow fine tuning of the safety valve D performance characteristics needed to meet the steam system conditions that vary at each installation. A sharp, clean opening assures long valve seat life and reduced maintenance costs . Consistent opening and closing pressures contribute to efficient steam system operation. Because the 1811 valve is not totally enclosed, upon actuation the system media will escape from the following locations: 1. The valve outlet that is the main discharge area. 2. The open yoke, which will also allow a small amount of steam to exhaust vertically. 3. The drain hole at the base of the valve. fact sheet

Open the catalog to page 1

fact sheet Features and Benefits Specifications Seat Bushing INLET SIZES 1.25” (31.75 mm) through 6” (152.4 mm) flanged INLET RATINGS ANSI Class 300 & 600 OUTLET SIZES 1.5” (38.1 mm) through 8” (203.2 mm) flanged Flat Seat Design OUTLET RATINGS ANSI Class 150 ORIFICE SIZES sizes: F through Q Ten TEMPERATURE RANGE -20°F (-28.9°C) to 1000°F (537.8°C) MATERIALS Alloy and carbon steel cast body with stainless steel trim is standard. Thermodisc™ Seat Design CERTIFICATION ASME B & PVC Section I and VIII Upper Adjusting Ring BLOWDOWN 4 percent BACK PRESSURE LIMIT percent of Set Pressure 20 Lower...

Open the catalog to page 2All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

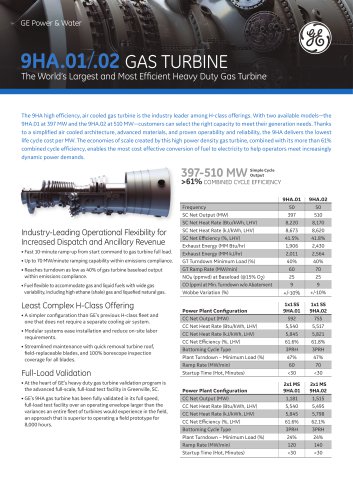

9HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages