Catalog excerpts

Consolidated* 13900 Series Pilot-Operated Safety Relief Valve Overview The Consolidated 13900 series pilot-operated safety relief valve from GE is designed specifically for high capacity steam applications and contributes to the overall efficiency and profitability of plant operations. Features and Benefits For system applications that require large discharge releasing capacities, GE’s 13900 valve series provides very reliable working economy and a simple, efficient valve design. In addition, its valve configuration simplifies valve installation and in-line valve maintenance. Greater Total System Efficiency main valve can handle extremely large relieving capacities, in The excess of 3 million pounds of steam per hour (1,360,777 kg/hr). It has a seven-to-one discharge capacity over a “T” type orifice, and a two-toone discharge capacity over a “W” type orifice. Improved Design total valve external configuration is considerably smaller in size, The and the valve is lighter in weight than a comparable spring-loaded valve. Because of these features, less space is required for valve installation. simple, efficient, and reliable direct acting valve design with few A components eliminates the need for excessive spare parts inventory and reduces maintenance time. Easy Installation and Maintenance Valve configuration is considerably smaller in size and lighter in weight than a comparable spring-loaded valve. This simplifies installation, field handling, testing, and valve maintenance. Valve maintenance is relatively simple and straightforward. The simple valve design means fewer parts, so less can go wrong, malfunctions can be readily diagnosed, and maintenance cost and process downtime can be very limited. To simplify valve maintenance, all main valve components are removable through the top bonnet of the valve. The pilot valve can be field tested and repaired without breaking inlet and outlet piping connections on the main valve. The pilot valve opening and closing is easily adjusted on a small test facility. Description The 13900 series pilot-operated safety valve is an ASME Section VIII-approved valve intended for use on compressible fluids. The valve design is simple. It consists of a small, conventional, fail-safe pilot safety valve and main valve. The metal-to-metal contact bearing surfaces between the disc and bushing eliminate overcompression of the main valve seat O-ring, located between the disc and bushing. By removing the pressure from behind the O-ring via two small slots when the valve is open and flowing, O-ring seal blowout is eliminated. A condensate drain hole in the disc facilitates drainage of any accumulated moisture in the upper disc cavity. The spring-loaded U-shaped Teflon® guide seal provides increased seat tightness as system pressure increases. The Teflon© material greatly lessens friction on the main disc and allows for reliable, dependable, and repeatable disc action. The seal spring load ensures sealing at all times. Teflon® guide rings eliminate metal-to-metal contact between the disc and guide, and eliminate friction. Main valve disc action is repeatable and reliable. The pilot valve action directly controls the pressure forces on the main valve disc and eliminates the need for a transfer valve. System pressure that actuates the pilot valve is transmitted through a simple, full-flow-design sensing tube. The sensing tube eliminates small orifice control parts and their possible clogging characteristics and is enclosed within the valve body, which protects it from damage and freezing. Pilot valve blowdown adjustment can be set independently of the main valve. The pilot valve can be adjusted and set before it is installed on the main valve. fact sheet

Open the catalog to page 1

fact sheet • The 13900 series valve can be used on any compressible fluid within the pressure and temperature limits of the valve, provided the fluid media exhibits characteristics similar to saturated steam. For applications other than steam, the open-lift lever cap should be reviewed for adequacy. If another cap design is required, it should be so stated. Four sizes of 13900 series valves are available: 114, 143, 176 and 200 in2 (735, 923, 1135 and 1290 cm2). For all sizes except the 200 in2 (1290 cm2), the largest possible relieving capacity is supplied for the valve inlet size...

Open the catalog to page 2All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

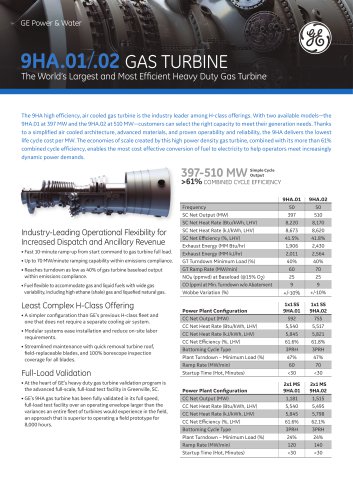

9HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages