Catalog excerpts

Baghouse Accessories Designed to reduce maintenance, labor, and overall operating costs.

Open the catalog to page 1

Solving Challenges Solutions that solve problems in dust collectors and enhance system performance. GE Energy’s accessory products are solutions to real problems. Our products are designed to decrease maintenance time and labor costs, while adding value to your system. Our innovative accessories offerings include: • Neutralite® conditioning agent • Neutralite® SR (spark retardant) • Visolite® leak detection system • Conical spring • Tensionor® suspension system • AC Tensioning Tool® • U-Channel door seal • Clean-On-Demand™ • Photohelic® gauge Tensioning products applied properly in reverse...

Open the catalog to page 2

Efficiency Enhancers Transfer bulk materials easily with Vacutrans™ cleaning system. The Vacutrans system is an industrial strength tool specifically designed to convert your compressed air supply into a high powered vacuum and material transferring system. The benefits of the Vacutrans system include: • Reduced maintenance time - quick and easy cleanup • Extended bag life - reduces abrasion on the clean side of the fabric filter when used to remove particulate buildup from the clean air plenum • No manual handling of dust - dust flows directly into the collector’s hopper, eliminating the...

Open the catalog to page 3

Cages Bag-to-cage fit is critical for proper performance and collection efficiency. Rounded edges Maximize Filter Bag Life The type of cage you buy will affect the life of your filter bags. Cages should be designed to optimize filter performance and promote longer bag life. Poorly manufactured cages allow over-flexing of the fabric, abrasion, holes, and eventually lead to filter failure. Avoid crimped or scalloped bottom pans, tapered or bowed cages, and cages that have wires welded on the outside of collars or pans. Consistent diameter The GE Cage Difference GE Energy manufactures cages...

Open the catalog to page 4

Visolite® Leak Detection One of the brightest leak detection products available for baghouses—we invented it! Locate Leaks in Your Baghouse Quickly and Easily The Visolite Leak Detection System reduces the time plant personnel spend identifying tears, holes, and bad seals in bags. Visolite is a lightweight fluorescent powder that is injected into the baghouse. The powder follows the path of least resistance, accumulating around the source of leakage, whether it is a weak area in the filter media or a bad seal. A monochromatic light is then used to pinpoint the exact location of air leakage...

Open the catalog to page 5

Neutralite® Powder Creates a more efficient and porous dustcake. The Importance of Building a Protective Dustcake For a baghouse to operate efficiently, the fabric filters must capture and release particulate during the cleaning cycle. The effectiveness of this process depends on the development of the dustcake (initial control layer of dust) that protects the fabric interstices. A variety of particle sizes and shapes are needed to produce an efficient and porous dustcake. Particles that are similar shapes and sizes will form a very dense dustcake that restricts airflow. Neutralite® vs....

Open the catalog to page 6

Clamps Protection for your filter investment. When you buy new filters, buy new clamps. GE Clamps are Designed to Protect Your Filter Bags and Make Installation Easy Our clamps increase bag life by decreasing leakage and abrasion. Each clamp is designed specifically to ensure bag sealing and make filter installation simple. We offer a variety of designs and sizes engineered to meet your particular needs. They can be used with raw edge, cord, hem, or sleeve constructed bags and some 1 pleated filter elements. There are several reasons why clamps can fail: • Misapplication • Misplacement •...

Open the catalog to page 7

Tensioning Provides proper support to filter bags. Tensioning is Critical to Reverse Air Baghouse Operation Improper tensioning is one of the main causes of bag failure in reverse air baghouses. Excessive tensioning causes harmful stress on the fabric yarns and sewing threads and also prohibits movement necessary for dustcake release. We have developed many tensioning assemblies to best fit your application. The assemblies are available in chrome silicon steel for moderately elevated temperatures or 17-7 PH stainless steel for high temperature applications. Conical Spring Unlike a linear...

Open the catalog to page 8

Valves/Valve Kits Improve your baghouse cleaning system. The Efficiency of Your Pulse-Jet Cleaning System Relies on Proper Valve Operation Diaphragm and solenoid valves work together for efficient operation of the baghouse cleaning system. GE Energy can provide technical support, complete rebuild instructions, and an in-house engineering staff to assist your crews with site-specific valve problems. We supply a a wide variety of valves to accurately fit your application. • For extremely corrosive applications, valves can be coated in a variety of finishes • Integral solenoid valves are...

Open the catalog to page 9

Door Seal/Access Doors Help prevent outside air from leaking into the system. Avoid Corrosion, Emissions, and Production Loss by Keeping Access Doors Sealed Properly A door seal is one of the most overlooked issues in dust collector maintenance. If your doors are not sealed properly, many problems can occur within your system, including: • Corrosion of doors and walls • Fugitive emissions • Production losses • Maintenance problems • Reduction of airflow across filters due to condensation and blinding GE Energy has developed a variety of door seals to prevent leakage of outside air into your...

Open the catalog to page 10

Gauges Small changes now can mean big savings in the long run for your operation. Keep Differential Pressure in Check with Pressure Measurement Gauges High differential pressure in the baghouse can cause damage to filter bags, decrease airflow in your baghouse, and increase operating costs. You can monitor differential pressure with one of our pressure measurement gauges, and even allow your collector to clean on demand! Magnehelic® Gauge for Continuous Pressure Measurement The Magnehelic gauge is used to measure the differential pressure between the clean gas side and the dirty gas side of...

Open the catalog to page 11All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

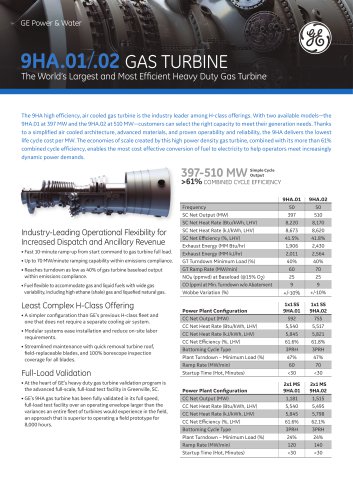

9HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages