Catalog excerpts

GE installed emPact on one of WBI Energy’s Waukesha L7044GSI engines at the Baker Booster station in Montana. Performance has exceeded expectations. Seven weeks after emPact was operational, it was still maintaining emissions below 0.10 g/bhp-hr for both NOx and CO—without manual adjustment—even as site conditions changed. Quarterly source testing performed ten weeks after installation showed no change in emission levels. GE Power & Water’s Distributed Power portfolio of innovative solutions gives businesses and communities around the world the ability to generate reliable and efficient power at or near the point of use, anytime—on the grid or off. Our product portfolio features Aeroderivative gas turbines, Jenbacher gas engines, and Waukesha gas engines ranging from 120 kW–100 MW. Distributed Power provides customers of all types—including industrial businesses, developing communities, government agencies managing disaster relief, and other emergency power situations—the ability to generate reliable, sustainable power whenever and wherever it is needed. Learn more at www.ge-distributedpower.com. Says WBI Maintenance Supervisor David Wedel, "emPact uses an O2 sensor that is specifically set up for natural gas. That is a huge strength. It helps us get the right mixture to the catalyst to help it convert. It requires less babysitting to meet emissions and holds the engine on-target better, which is an obvious need in meeting your air/fuel emission standards. emPact adjusts through varying conditions—both load and ambient—so it’s certainly much better than what we’ve had in the past.” The emPact emission control system is one trusted solution, from one trusted source. GE Power & Water 1101 West St. Paul Avenue Waukesha, WI USA 53188-4999 Phone: +1 (262) 547-3311 Fax: +1 (262) 549-2795 The emPact Emission Control System installed at WBI Energy's Baker Booster Station in Montana. ©2014 General Electric Company All Rights Reserved GEA31169 03/14 (77257) GE Power & Water Distributed Power The all-in-one emissions solution that’s changing everything. GE's Waukesha* emPact Emission Control

Open the catalog to page 1

7 With the emPact emission control system for Waukesha VHP gas engines, GE effectively combines all the emissions-related components of an engine into one comprehensive control system that can keep your emissions in compliance. The system is factory-designed to optimize the interaction between components, resulting in excellent system performance. emPact means advantages The emPact system is comprised of a Waukesha VHP engine, GE-supplied 3-way catalyst and air/fuel ratio control. Oxygen (O2) sensors read post-catalyst exhaust composition to automatically adjust the engine’s air/fuel ratio,...

Open the catalog to page 2

GE installed emPact on one of WBI Energy’s Waukesha L7044GSI engines at the Baker Booster station in Montana. Performance has exceeded expectations. Seven weeks after emPact was operational, it was still maintaining emissions below 0.10 g/bhp-hr for both NOx and CO—without manual adjustment—even as site conditions changed. Quarterly source testing performed ten weeks after installation showed no change in emission levels. GE Power & Water’s Distributed Power portfolio of innovative solutions gives businesses and communities around the world the ability to generate reliable and efficient...

Open the catalog to page 3

GE installed emPact on one of WBI Energy’s Waukesha L7044GSI engines at the Baker Booster station in Montana. Performance has exceeded expectations. Seven weeks after emPact was operational, it was still maintaining emissions below 0.10 g/bhp-hr for both NOx and CO—without manual adjustment—even as site conditions changed. Quarterly source testing performed ten weeks after installation showed no change in emission levels. GE Power & Water’s Distributed Power portfolio of innovative solutions gives businesses and communities around the world the ability to generate reliable and efficient...

Open the catalog to page 4All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

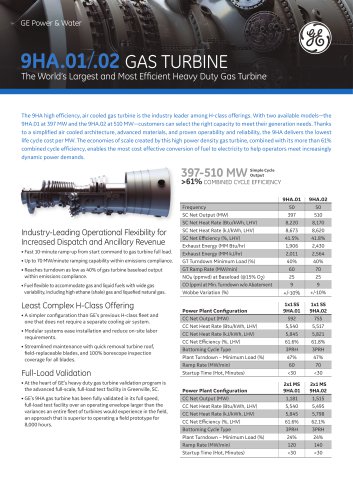

9HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages