Catalog excerpts

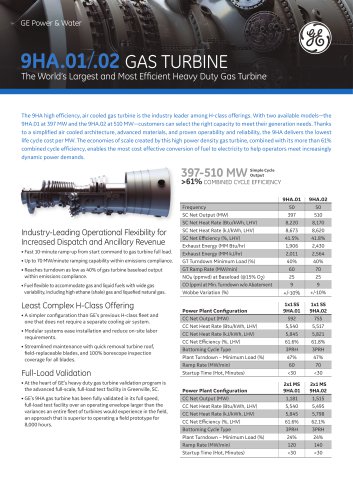

The World’s Largest and Most Efficient Heavy Duty Gas Turbine The 9HA high efficiency, air cooled gas turbine is the industry leader among H-class offerings. With two available models—the 9HA.01 at 397 MW and the 9HA.02 at 510 MW—customers can select the right capacity to meet their generation needs. Thanks to a simplified air cooled architecture, advanced materials, and proven operability and reliability, the 9HA delivers the lowest life cycle cost per MW. The economies of scale created by this high power density gas turbine, combined with its more than 61% combined cycle efficiency, enables the most cost effective conversion of fuel to electricity to help operators meet increasingly dynamic power demands. Simple Cycle Output >61% COMBINED CYCLE EFFICIENCY Industry-Leading Operational Flexibility for Increased Dispatch and Ancillary Revenue • Fast 10-minute ramp-up from start command to gas turbine full load. • Up to 70 MW/minute ramping capability within emissions compliance. • Reaches turndown as low as 40% of gas turbine baseload output within emissions compliance. • uel flexible to accommodate gas and liquid fuels with wide gas F variability, including high ethane (shale) gas and liquefied natural gas. Least Complex H-Class Offering • simpler configuration than GE’s previous H-class fleet and A one that does not require a separate cooling air system. • odular systems ease installation and reduce on-site labor M requirements. • treamlined maintenance with quick removal turbine roof, S field-replaceable blades, and 100% borescope inspection coverage for all blades. Full-Load Validation • t the heart of GE’s heavy duty gas turbine validation program is A the advanced full-scale, full-load test facility in Greenville, SC. • E’s 9HA gas turbine has been fully validated in its full speed, G full-load test facility over an operating envelope larger than the variances an entire fleet of turbines would experience in the field, an approach that is superior to operating a field prototype for 8,000 hours. Power Plant Configuration CC Net Output (MW) CC Net Heat Rate (Btu/kWh, LHV) CC Net Heat Rate (kJ/kWh, LHV) CC Net Efficiency (%, LHV) Bottoming Cycle Type Plant Turndown – Minimum Load (%) Ramp Rate (MW/min) Startup Time (Hot, Minutes) Power Plant Configuration CC Net Output (MW) CC Net Heat Rate (Btu/kWh, LHV) CC Net Heat Rate (kJ/kWh, LHV) CC Net Efficiency (%, LHV) Bottoming Cycle Type Plant Turndown – Minimum Load (%) Ramp Rate (MW/min) Startup Time (Hot, Minutes) Frequency SC Net Output (MW) SC Net Heat Rate (Btu/kWh, LHV) SC Net Heat Rate (kJ/kWh, LHV) SC Net Efficiency (%, LHV) Exhaust Energy (MM Btu/hr) Exhaust Energy (MM kJ/hr) GT Turndown Minimum Load (%) GT Ramp Rate (MW/min) NOx (ppmvd) at Baseload (@15% O2) CO (ppm) at Min. Turndown w/o Abatement Wobbe Variation (%)

Open the catalog to page 1

Efficient, Flexible, Reliable Power GE offers the world's largest range of heavy Product Platform Evolution H-Class Gas Turbine Orders First 9H GasTurbine Enters Commercial Operation Full Speed, No Load Testing of the 7H GasTurbine Full Speed, No Load Testing of the 9H GasTurbine H System* Tech no logy Introduced F-Class Technology First First 7H GasTurbine Enters Commercial Operation GE Launches the FlexEfficiency 50* Combined Cycle Power Plant for 50 Hz Regions that Can Provide More than 61%Combined Cycle Efficiency GE Launches the FlexEfficiency 60* Combined Cycle Power Plant for 60 Hz...

Open the catalog to page 2All GE Gas Turbines catalogs and technical brochures

-

LM6000

1 Pages

-

STEAM POWER SERVICES CATALOG

94 Pages

-

NUCLEAR POWER PRODUCT CATALOG

28 Pages

-

STEAM POWER PRODUCT CATALOG

61 Pages

-

2018 POWER SERVICES CATALOG

111 Pages

-

7E POWER PLANTS

1 Pages

-

LMS100®

7 Pages

-

LMS100 POWER PLANTS

1 Pages

-

LM2500 POWER PLANTS

1 Pages

-

LM6000 POWER PLANTS

1 Pages

-

6B POWER PLANTS

2 Pages

-

9E & GT13E2 POWER PLANTS

2 Pages

-

6F POWER PLANTS

2 Pages

-

7F POWER PLANTS

2 Pages

-

9F.04, 9F.05, 9F.06

2 Pages

-

Reciprocating Engines

2 Pages

-

69663_aftermkt_bro

4 Pages

-

1483_1112.indd

1 Pages

-

18900_5_15

8 Pages

-

66535_reman_bro_redo_FINAL

6 Pages

-

1212_1012

12 Pages

-

Powering the world 2016

72 Pages

-

raising the bar

8 Pages

-

Waukesha* gas engines

12 Pages

-

6 F. 01 Gas Turbine

4 Pages

-

7HA.01 / .02 GAS TURBINE

2 Pages

-

Dresser? Turbine Meters

8 Pages

-

HSR line

6 Pages

-

CNG In A Box? system

16 Pages

-

Becker? T-Ball? Anti-Surge Valve

12 Pages

-

Becker V0 Control Valves

12 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

7E.03 HDGT

15 Pages

-

Baghouse Accessories

12 Pages

-

Fabric Filter Bags & Cages

2 Pages

-

GE10 15 ppm combustor

3 Pages

-

GE10-1 Gas Turbine

8 Pages

-

GE10-2 15 ppm combustor

3 Pages

-

Frame 6 Gas Turbine

3 Pages

-

GE10 Gas Turbine

6 Pages

-

Heavy Duty Gas Turbine Products

24 Pages

-

Product Structuring

5 Pages

-

Gas Turbines Catalog

31 Pages

Archived catalogs

-

7HA gas turbine

4 Pages

-

9HA Gas turbine

4 Pages