Catalog excerpts

Positive Displacement Compressors Oil-free rotary screw

Open the catalog to page 1

Oil-free rotary screw Single-source solutions For applications where process gas conditions and gas composition may vary, oil-free rotary screw compressors offer the best of both worlds – the reliability and rotary motion of centrifugal compressors plus the surge-free performance of positive displacement (reciprocating) compressors. Screw compressors are also the best choice for applications in which no other compressor can operate economically. They can easily handle dirty, polymerforming process gases and process gases with entrained liquids. How it works Compression is achieved by the...

Open the catalog to page 2

1 Precise rotors and shafts • Machined from carbon steel forgings or special-use rotor materials • Optimized rotor profile • Critical internal clearances maintained by seal strips machined on each rotor lobe tip • Dynamically balanced rotors 2 Shaft seals that isolate and protect • Each of four journal bearings is isolated from the compression chamber • Seals prevent outward leakage of process gas and inward leakage of lubricant • Space for floating carbon ring, labyrinth, dry gas or mechanical contact seals (with or without buffer) • Seals are carefully selected to properly handle the...

Open the catalog to page 3

Oil-free rotary screw compressor features Standard Design Parameters • Multiple internal volume ratios: 1.34, 1.64, 2.19, 2.69, 3.16 • Pressure differential: L models, 10 to 150 psi; 0.7 to 10.3 bar S models, 10 to 250 psi; 0.7 to 17.2 bar • Casing design pressure: Cast steel, 225 to 300 psig; 15.5 to 20.7 barg • Molecular weights: 2 to 140 • Inlet temperature: -50° to 250°F; -45.5° to 121°C • Maximum temperature: 550°F; 288°C • Rotor tip speed: 150 to 550 ft/s; 45 to 168 m/s Custom designed. Precision built. Optional design parameters • Multi-staging compressor frames can increase overall...

Open the catalog to page 4

Successful in the most demanding applications With 12 basic models and a range of flow and pressure configurations, GE’s oil-free screw compressors are the top choice for hundreds of the most demanding compression applications. The screw compressor combines the advantages of positive displacement (like a reciprocating compressor) with the rotary motion of a centrifugal compressor to provide a wide range of operating capabilities. Oil-free rotary screw compressors are designed for maximum reliability and efficiency in challenging operating conditions. Their rugged design allows them to...

Open the catalog to page 5

Unique characteristics of oil-free screw compressors Process control The design of the screw compressor can accommodate for run-in on air or nitrogen. For practical purposes, aside from small changes in volumetric and adiabatic efficiencies, the flow of an oil-free screw compressor is proportional to speed. Installation flexibility Discharge connections are located vertically on the casing and may be arranged in an “up” or “down” position. When both connections are in a vertically “up” position, the compressor/driver may be located on grade, reducing foundation costs and facilitating...

Open the catalog to page 6

Comprehensive pre-installation testing ensures peak performance in the field Rigorous testing to ensure field performance Every oil-free screw compressor we manufacture must pass stringent testing and inspection procedures. Every component is thoroughly tested before assembly, then the entire assembled compressor goes through a comprehensive testing and inspection process. Rotating elements Each rotor is assembled with the timing gear and thrust collar subassemblies, then dynamically balanced to ensure top performance upon installation. Rotors • Physical and chemical properties are verified...

Open the catalog to page 7

Oil & Gas Global Services Our Global Services teams provide a complete spectrum of services for the oil and gas industry from installation to maintenance, refurbishment and uprates. We support the entire product value chain from large gas and steam turbines to pumps and valves for both our own and multivendor equipment. We offer an extensive portfolio of proactive and interactive service products such as Conversions, Modifications & Uprates, Condition-based Maintenance and Contractual Service Agreements. These complement our traditional service product offerings of OEM-quality spare parts,...

Open the catalog to page 8

Nuovo Pignone S.p.A. Via Felice Matteucci, 2 50127 Florence, Italy T +39 055 423 211 F +39 055 423 2800 GE Oil & Gas 1333 West Loop South, Suite 800 Houston, Texas 77027-9116 USA T +1 713 803 0900 F +1 713 803 0499 GE Oil & Gas Operations, LLC 3300 Medalist Drive Oshkosh, Wisconsin 54902 USA T +1 920 237 6000 F +1 920 237 6195 The information contained herein is general in nature and is not intended for specific construction, installation or application purposes. GE reserves the right to make changes in specifications or add improvements at any time without notice or obligation. ©2008...

Open the catalog to page 9All GE Compressors catalogs and technical brochures

-

Iron & Steel

8 Pages

-

2018 Power Services Catalog

111 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

Virtual Natural Gas Pipeline

5 Pages

-

Dresser? Turbine Meters

8 Pages

-

Portable diagnostics

3 Pages

-

Flexibility & performance

3 Pages

-

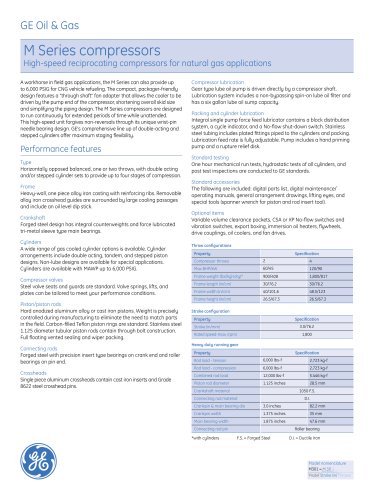

M Series compressors 2013

12 Pages

-

Roots Type H

11 Pages

-

M Series compressors 2010

12 Pages

-

High-speed solutions

6 Pages

-

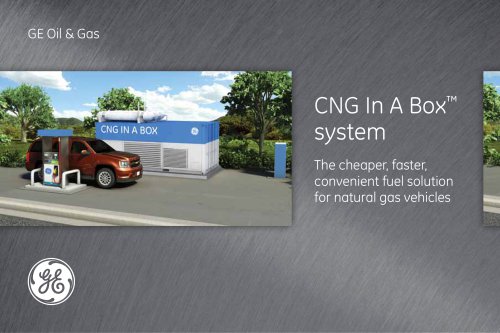

CNG In A Box ? system

16 Pages

-

HE-S

2 Pages

-

API 618

2 Pages

-

Reciprocating Compressors

5 Pages

-

Roots * Turbo Blower

8 Pages

-

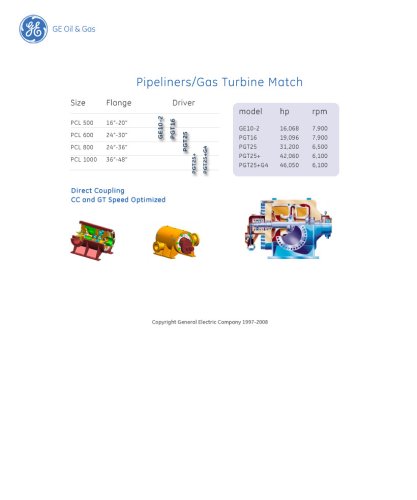

Pipeliners-Gas Turbine Match

1 Pages

-

global service

16 Pages

-

Centrifugal Compressors SRL

20 Pages

-

Centrifugal & Axial Compressors

28 Pages