Website:

GE Compressors

Website:

GE Compressors

Group: GE Energy

Catalog excerpts

An operator in Alaska wanted a more efficient way to install cased-hole completions without compromising wellbore cleaning. Jeopardizing the completion installment would be detrimental to a successful development of the wellbore. The Wellbore Intervention team from Baker Hughes, a GE company (BHGE), proposed a one-trip completion installment using the TRAILBLAZER™ wellbore preparation tool. The TRAILBLAZER is an integrated, cost-effective tool deployed as part of the downhole bottomhole assembly (BHA) to provide additional cleaning during wellbore installation. The tool is designed with a large inside diameter to accommodate high flow rates for effective cleaning and optimized production flow once the well is online. Dedicated wellbore cleanup (WBCU) runs are customary prior to the installment of completion equipment to ensure the chances of a successful completion. When deploying the TRAILBLAZER tool in an integrated completion string, this dedicated WBCU may be eliminated. Various optional connections allow the TRAILBLAZER tool to be fitted into the completion string, minimizing the need for crossovers. Chosen for this job was the 5 7/8-in. OD TRAILBLAZER tool that incorporated four technologies, including: • Scraper blades with 360° coverage • Magnets that collect and capture ferrous debris • Brushes that assist the scraper in removing debris from the casing ID and polish packer setting area • Stabilizer to maintain and centralize the tool, and ensure that captured debris at the magnets cannot fall off The completion BHA was spaced out to position the TRAILBLAZER tool at the bottom of the BHA and run past the perforations. The completion equipment was installed successfully eliminating a clean-up trip and providing a one-trip completion. Challenges • Debris was encountered while installing the completion • Various perforations to pass that could damage the packing elements of the completion Results • Installed cased-hole completion in one trip • Eliminated a clean-up trip • Reduced risks of having debris in the lower completion and jeopardizing further operations • Mitigated costs associated with post-job activities relating to rental tools • Saved 12 hours rig time by eliminating dedicated cleanup operation

Open the catalog to page 1

This successful installment led to the operator incorporating the TRAILBLAZER tool into the completion string as a standard practice going forward, saving the operator more than 12 hours of rig time per installment. Total projected savings per well are $100,000 USD. The TRAILBLAZER™ wellbore preparation tool can be fitted with custom-made connections to accommodate a customer’s need. bhge.com Copyright 2018 Baker Hughes, a GE company, LLC (“BHGE”). All rights reserved. The information contained in this document is company confidential and proprietary property of BHGE and its affiliates. It...

Open the catalog to page 2All GE Compressors catalogs and technical brochures

-

Iron & Steel

8 Pages

-

2018 Power Services Catalog

111 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

Virtual Natural Gas Pipeline

5 Pages

-

Dresser? Turbine Meters

8 Pages

-

Portable diagnostics

3 Pages

-

Flexibility & performance

3 Pages

-

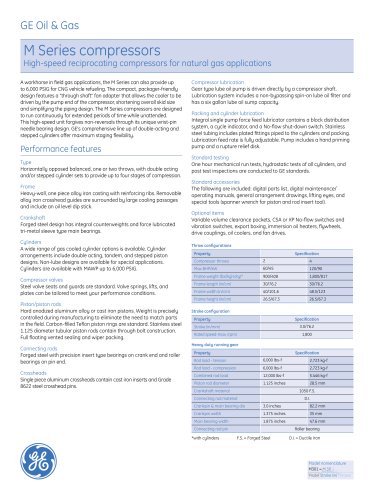

M Series compressors 2013

12 Pages

-

Roots Type H

11 Pages

-

M Series compressors 2010

12 Pages

-

High-speed solutions

6 Pages

-

CNG In A Box ? system

16 Pages

-

HE-S

2 Pages

-

API 618

2 Pages

-

Reciprocating Compressors

5 Pages

-

Roots * Turbo Blower

8 Pages

-

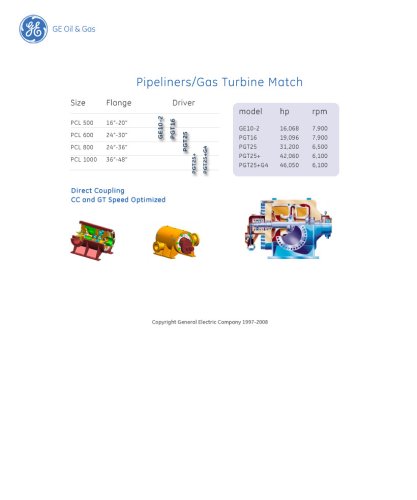

Pipeliners-Gas Turbine Match

1 Pages

-

global service

16 Pages

-

Centrifugal Compressors SRL

20 Pages

-

Centrifugal & Axial Compressors

28 Pages