Catalog excerpts

I General view of the AN250 testing facilities at the GE Nuovo Pignone Florence plant. NUOVO PIGNONE SUCCESSFULLY TESTS NEW AN250 AXIAL COMPRESSOR Greater Capacity for Use in LNG Applications By Roberto Chellini GE’s Oil & Gas Business has been specializing in the design and manufacture of centrifugal and axial compressors used in LNG refrigerating plants since 1985. In some cases, mainly tied to the volume of gas to be handled by a refrigerating line, the choice of a centrifugal or axial machine is left to customer preferences. Several LNG lines in the range of 3.8 million t/y (million tons per year) feature an AN200 axial compressor, designed to handle 7.7 million cfh (220,000 m 3 /h) of gas, as a first mixed refrigerant (MR) compression stage. A new machine with 20% increased capacity was designed for plants in the range of 4.1 million t/y steam. The AN200 was used as a starting point by adding a 0 stage on the front and removing the last stage at the end of the flow path. This results in an axial compressor with a design capacity of 8.7 million cfh (249,000 m3/h). The acquisition of the order for the Tangguh LNG job in Indonesia, which will be jointly operated by BP on behalf of BPMIGAS (Indonesian Government) and another production sharing DECEMBER 2005 company, was the occasion to begin The second train consists of an the new project. FR7EA gas turbine driving the 3MCL1405 centrifugal compressor The Tangguh 4.1 million t/y project (propane cycle) + BCL804 (HP MR) is using the Air Products APCI process and finally the starter-helper steam scaled up from the Bintulu LNG lines turbine. where the AN200 are performing the The AN250 was built similarly to first stage MR job. the AN200 with a welded 3.5 Ni steel In Tangguh, the layout of the two casing for low temperature operarefrigerating cycles (propane and mixed refrigerant) is slightly different from Bintulu layout, where the refrigerating process is subdivided into three cycles to better utilize the power of the Frame 7 gas turbine drivers and their steam turbine starterhelper units. One train features an FR7EA gas turbine driving the AN250 axial compressor (for LP MR) + MCL1002 centrifugal compres- I The new AN250 axial compressor assembled on the test bed dursor (for MP MR). At ing the validation test. This axial compressor is driven by an FR7EA the end of the string gas turbine and coupled, on the opposite end, to the MCL 1002 cenis the starter-helper trifugal compressor. This train serves the mixed refrigerant (MR) steam turbine. service of a 4.1 million t/y LNG line.

Open the catalog to page 1

I The AN250 rotor instrumented for the validation test. tion. After heat treatment, this casing can operate at temperatures as low as -148°F (-100°C) [design point -139°F (-95°C)] although the MR refrigerant gas will have an operating temperature at the compressor inlet around -22°F (-30°C) [-49°F (-45°C) during transients]. Stator and rotor blading are made out of 17-4-PH, also resistant to low temperatures. Variable stator vanes (VSV) are provided on the first seven stator rows — the angle of which can be adjusted from -35° to +10°. The system allows the flow to vary from 6.3 million to...

Open the catalog to page 2All GE Compressors catalogs and technical brochures

-

Iron & Steel

8 Pages

-

2018 Power Services Catalog

111 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

Virtual Natural Gas Pipeline

5 Pages

-

Dresser? Turbine Meters

8 Pages

-

Portable diagnostics

3 Pages

-

Flexibility & performance

3 Pages

-

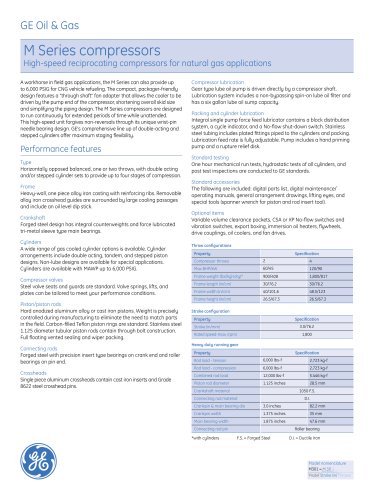

M Series compressors 2013

12 Pages

-

Roots Type H

11 Pages

-

M Series compressors 2010

12 Pages

-

High-speed solutions

6 Pages

-

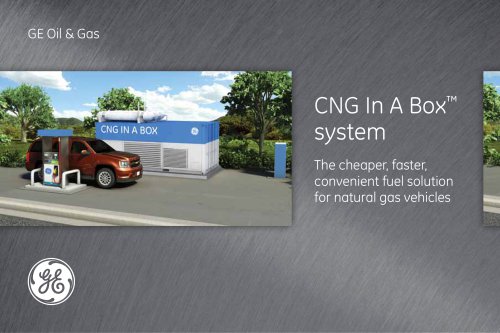

CNG In A Box ? system

16 Pages

-

HE-S

2 Pages

-

API 618

2 Pages

-

Reciprocating Compressors

5 Pages

-

Roots * Turbo Blower

8 Pages

-

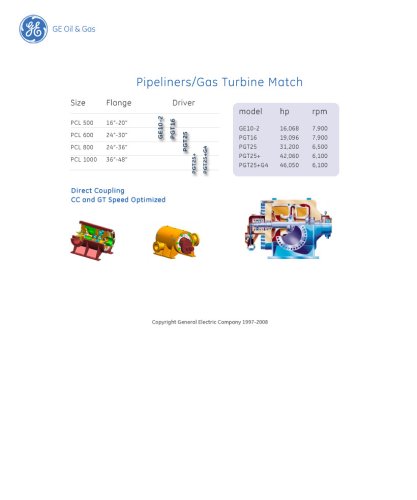

Pipeliners-Gas Turbine Match

1 Pages

-

global service

16 Pages

-

Centrifugal Compressors SRL

20 Pages

-

Centrifugal & Axial Compressors

28 Pages