Website:

GE Compressors

Website:

GE Compressors

Group: GE Energy

Catalog excerpts

Integrated Turbine-Compressor Control

Open the catalog to page ١

Integrated Turbine-Compressor Control Maximize your turbo-machinery and process reliability and efficiency with GE’s Oil & Gas integrated control solution for turbines and compressors. The GE Integrated Turbine-Compressor Control (ITCC) system is the OEM solution designed to provide complete integrated control, protection and monitoring for optimum protection of the compressor from harmful surge conditions, while enhancing the process system efficiency and availability. It is already installed on more than 150 TurbineCompressor units in operation worldwide. This integrated control solution...

Open the catalog to page ٢

Significantly Improved Compressor Station Efficiency & Reliability ITCC is a fully digital control that delivers enhanced machinery performance. The independent actions of separate turbine and compressor controls can adversely impact the process, and in turn, diminish the overall efficiency of the machinery. By integrating the compressor and turbine controls into one common system, the GE ITCC can optimize performance and maintain the necessary degree of reliability. The ITCC simplifies operations and provides more accurate operating data faster. By providing access to a variety of types of...

Open the catalog to page ٣

Main Features — General Purpose I/O Discrete I/O Analog I/O Temperature Monitoring GE has a heritage of over 30 years of successful operation of electronic turbine control systems. The SPEEDTRONIC™ Mark VI turbine control system is the current state-ofthe-art control for GE turbines. It is designed as a complete integrated control, protection, and monitoring system for generator and mechanical drive applications of gas turbines and steam turbines. — Application Specific I/O Speed (Pulse Rate) Inputs Flame Detection Servo Valve Interface Vibration / Proximitor Inputs Dynamic Pressure Inputs...

Open the catalog to page ٤

Operator Interface Software Maintenance Tools The operator interface is commonly referred to as the Human-Machine Interface (HMI). It is a PC with a Microsoft® Windows® operating system supporting client/server capability, a CIMPLICITY® graphics display system, a Control System Toolbox for maintenance, and a software interface for the Mark VI and other control systems on the network. It can be applied as: The Mark VI is a fully programmable control system. Application software is created from in-house software automation tools that select proven GE control and protection algorithms and...

Open the catalog to page ٥

Turbocompressor Control Application The Mark VI / Mark VIe controllers and GE Fanuc PLC’s can integrate in one common platform all the sequencing, controls and protection functions that are necessary to provide coordinated and safe operation of a turbocompressor unit. This capability typically includes: — Gas turbine and associated auxiliaries control and protection — Centrifugal compressor anti-surge control — Centrifugal compressor load sharing control — Centrifugal compressor dry gas seals control — Process valve sequencing — Process gas cooler control — Process gas scrubber level...

Open the catalog to page ٦

Faster Response to Minimize Surge Events Combining turbine and load compressor control in a single platform provides numerous advantages to the end-user: Operating compressors on the verge of surge can increase process operating range and overall efficiency, but the practice also contains inherent risk. The GE integrated control system minimizes — Common spares for both turbine and that risk utilizing proprietary algorithms, precision compressor control systems reduces overall instrumentation, and fast-acting valves thereby spares inventory requirements. enabling the compressor to be...

Open the catalog to page ٧

Nuovo Pignone S.p.A. via F, Matteucci, 2 50127 Florence - Italy T +39 055 423211 F +39 055 4232800 www.geoilandgas.com GE imagination at work COMK/MARK 876/II - Designed by: Studio Tre Fasi Printed by: Sagraf - 12-2005 ©2005 Nuovo Pignone S.p.A. all rights reserved

Open the catalog to page ٨All GE Compressors catalogs and technical brochures

-

Iron & Steel

8 Pages

-

2018 Power Services Catalog

111 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

Virtual Natural Gas Pipeline

5 Pages

-

Dresser? Turbine Meters

8 Pages

-

Portable diagnostics

3 Pages

-

Flexibility & performance

3 Pages

-

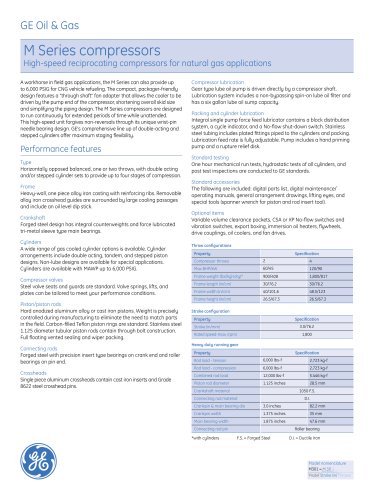

M Series compressors 2013

12 Pages

-

Roots Type H

11 Pages

-

M Series compressors 2010

12 Pages

-

High-speed solutions

6 Pages

-

CNG In A Box ? system

16 Pages

-

HE-S

2 Pages

-

API 618

2 Pages

-

Reciprocating Compressors

5 Pages

-

Roots * Turbo Blower

8 Pages

-

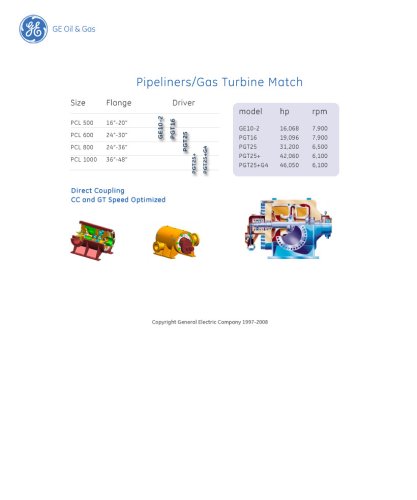

Pipeliners-Gas Turbine Match

1 Pages

-

global service

16 Pages

-

Centrifugal Compressors SRL

20 Pages

-

Centrifugal & Axial Compressors

28 Pages