Catalog excerpts

Centrifugal & Axial Compressors

Open the catalog to page 1

GE Centrifugal & Axial Compressors 3 Tradition, Experience and Innovation SRL Integrally Geared series Axial Compressors AN series Compressor Components Oil and Gas Seal Systems Control Systems Test Facilities Training Exploration and Production, Floating Production Units, LNG Pipeline and Storage Refinery and Petrochemicals Compressor Specifications Product Line Range GE Centrifugal & Axial Compressors

Open the catalog to page 2

Tradition, Experience and Innovation GE’s Oil & Gas Business manufactures a complete range of centrifugal compressors for all major compression applications. They are used in oil & gas production, gas transportation, refinery and petrochemical industries, fuel gas boosting and other similar processes. We hold the record of key milestones for centrifugal compressor applications having designed and manufactured the first high pressure compressors for ammonia and urea plants, the most powerful compressors for offshore applications (over 30,000 HP) and re-injection compressors with delivery...

Open the catalog to page 3

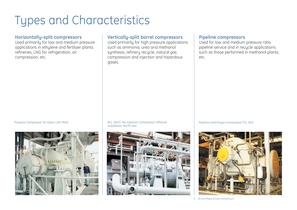

Types and Characteristics Horizontally-split compressors Vertically-split barrel compressors Pipeline compressors Used primarily for low and medium pressure applications in ethylene and fertilizer plants refineries, LNG for refrigeration, air compression, etc. Used primarily for high pressure applications such as ammonia, urea and methanol synthesis, refinery recycle, natural gas compression and injection and hazardous gases. Used for low and medium pressure ratio pipeline service and in recycle applications such as those performed in methanol plants, etc. Propane Compressor for Qatar LNG...

Open the catalog to page 4

Axial compressors Single stage overhung compressors Integrally geared compressors Used for low pressure, high flow applications such as catalytic cracking plants, air service, air separation, LNG, nitric acid and GTL applications. Used as boosters or recycle compressors in many petrochemical applications, such as polyethylene, polypropylene, ethylene oxide, chlorine, sulfuric acid plants, MVR. Used for low and medium pressure air, steam and inert gas, and fuel gas service and in petrochemical applications. Mixed Refrigerant Compressor for LNG Plant DH Single Stage overhung compressor for...

Open the catalog to page 5

MCL / V series 2MCL Horizontally split compressor being machined MCL compressors are designed in several sizes and pressure ratings to cover different applications. The compressor casing is either cast (cast-iron, cast steel) or fabricated. The diaphragms are cast-iron, cast steel or fabricated. The impellers and diffusers are selected from a wide range of standard stages in accordance with the application and desired performance. The radial and thrust bearings are of the tilting pad type. Shaft-end seals are mainly dry gas seals but can be labyrinths or oil film seals. Inter-stage leakages...

Open the catalog to page 6

Double stage models (2MCL) are used when intermediate cooling is required or when a process calls for two separate compression stages. 2MCL compressors have the same general features as the MCL type with the two compression stages in a back-to-back arrangement. Additional side stream nozzles can be provided with the 3MCL model for special requirements such as in refrigeration applications, particularly for propane in LNG plants. All connections can be oriented upward or downward to meet plant layout needs. 7 GE Centrifugal & Axial Compressors

Open the catalog to page 7

BCL, RB, VH series These compressors are designed to cover a wide range of applications and pressures (hydrogen mixtures, hazardous gases, high pressure). Casings can be rolled steel or forged with one or two end covers bolted or secured by shear rings. For improved performance, diaphragms are, when practical, 100% machined. Radial and thrust bearings are of the tilting pad type. Active Magnetic Bearings are also available as an option. End seals are of the dry gas type and other sealing solutions are also available. In addition to conventional labyrinths, inter-stage seals can be abradable...

Open the catalog to page 8

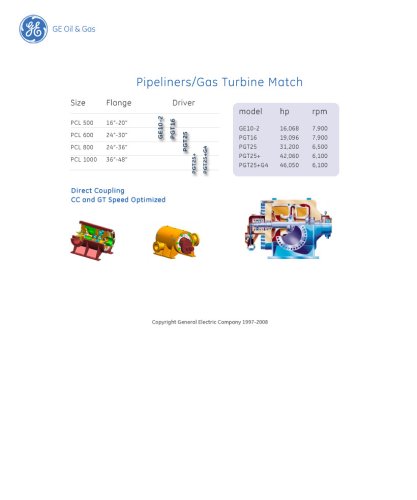

PCL series These compressors have been designed to meet the range of flow and compression ratios required by gas pumping stations. A variety of standard casing sizes are available to cover a wide range of gas flow. The same casing can house different numbers of impellers to optimize performance in terms of efficiency, compression ratio and operating range. Field modification of the impeller configuration can be made to accommodate changes in operating conditions. The compressor casings are made of forged steel to provide maximum material strength and metallurgical stability. Vibration-free...

Open the catalog to page 9

SRL Integrally Geared Series Integrally Geared Compressors are used in several petrochemical applications, either for low-flow/high pressure, or high-flow/low pressure conditions. This type of compressor has a bull gear and from one to four high speed pinions. One or two impellers can be mounted on each pinion-shaft. Optimal impeller speed and the ability to inter-cool compression stages guarantee very high efficiency. Due to its rugged mechanical design, this type of machine has very high reliability and is easy to maintain. A large variety of gases can be handled by this compressor line...

Open the catalog to page 10

SRL / DH series Overhung compressors are mainly used as boosters in petrochemical applications or for recycle in polypropylene and polyethylene plants. The single-stage overhung configuration is simple and easy to maintain. Almost all gases can be handled by this type of compressor with appropriate construction materials and seal systems. GE Centrifugal & Axial Compressors

Open the catalog to page 11

Blowers D series The Blower compressor is a low-pressure, single-stage overhung design typically utilized where a tough process gas application requires a relatively high flow of gas at a moderate differential pressure. It features a compact, efficient design and the ability to handle a wide range of applications. Features like three-piece casing construction, horizontally split bearing housing and our exclusive impeller balance ring are examples of how this compressor is designed from the ground up to provide maximum reliability and serviceability to its operators. These compressors offer...

Open the catalog to page 12All GE Compressors catalogs and technical brochures

-

Iron & Steel

8 Pages

-

2018 Power Services Catalog

111 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

Virtual Natural Gas Pipeline

5 Pages

-

Dresser? Turbine Meters

8 Pages

-

Portable diagnostics

3 Pages

-

Flexibility & performance

3 Pages

-

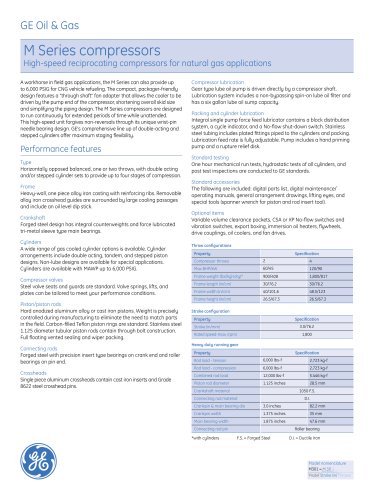

M Series compressors 2013

12 Pages

-

Roots Type H

11 Pages

-

M Series compressors 2010

12 Pages

-

High-speed solutions

6 Pages

-

CNG In A Box ? system

16 Pages

-

HE-S

2 Pages

-

API 618

2 Pages

-

Reciprocating Compressors

5 Pages

-

Roots * Turbo Blower

8 Pages

-

Pipeliners-Gas Turbine Match

1 Pages

-

global service

16 Pages

-

Centrifugal Compressors SRL

20 Pages